Date: 24 February 2015

And now, companies who are looking to gas fill for the first time can benefit from an enhanced version of the Firstfill machine.

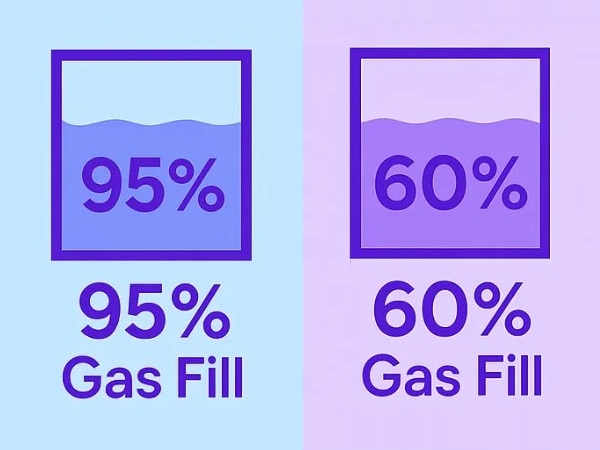

Originally launched as the perfect introductory machine, the enhanced Firstfill benefits from a compact size, with an improved rate of gas flow into the unit of 10 litres per minute. The new version has been brought into line with the Inagas suite of machines with the addition of the latest touch screen technology to allow full operator control over the gas filling process. It additionally benefits from adjustable gas fill percentages – the only entry level machine on the market to offer this - alongside a low gas supply alert, time to fill cycle, a unit counter to record the number of units filled per shift and semi-automated calibration.

Chris Kemp, Director at Inagas explains: “With ever rising efficiency standards in our industry, we at Inagas maintain that it is more important than ever for gas filling to be completely inclusive, regardless of the size and scale of those companies wishing to do so.

“We constantly invest in our solutions to ensure we can offer the very latest next generation technology and gas filling options to satisfy every level of production. We also appreciate that an investment in gas filling for the first time can be something of a daunting prospect, and with the enhanced Firstfill machine and our specialist support and advice, we can make the transition as simple as possible for our customers.”

Add new comment