Date: 16 May 2011

The production line for direct glazing integrates the manufacture of insulating glass units into the production process of the window sashes. A separate insulating glass production is eliminated – this saves time and reduces costs.

Glass plates are directly bonded to the corresponding window sashes and gas-filled on the automatic, vertical production line. In doing so, the processing of different glass sizes in a variable sequence as well as diverse window profiles is possible. "Our customers save up to 20 percent in production costs compared to the conventional glazing of window sashes with insulating glass", explains Klaus Puschmann, Product Manager at the Bystronic glass Technology Center Bystronic Lenhardt GmbH, which developed the sash’line. "As a result, the invest- ment in the line can pay for itself in less than a year."

Alan Levin, CEO and President of Northeast Building Products, in front of the press that was exclusively developed for the sash’line.

Tested and rated as good

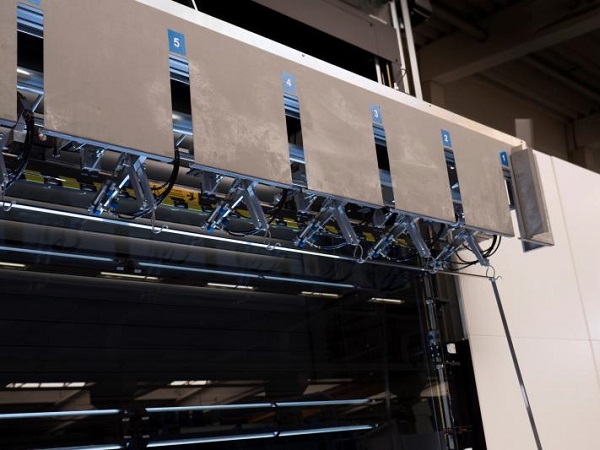

Bystronic glass presented the first sash’line for integrated window production at the GlassBuild America 2009 Exhibition. The window manufacturer Northeast Building Products based in Philadelphia (USA) purchased the first line and is still extremely satisfied with it today. "On average, we can produce up to 720 integrated sash profiles in mixed sequence, per shift on the sash’line. Previously we were only able to produce about half this amount. Even the previously extremely laborious inert gas filling is now completely automated. Thanks to the higher output, we can save one shift in production and can now guarantee our customers significantly lower delivery times", explains Alan Levin CEO and President of Northeast Building Products. In addition to the productivity, Northeast Building Products is still particularly impressed by the constant quality of the end products: "Our previous production that was primarily collaborative was defined by separate processing procedures and no continuous work sequence. Now, we place glass and window sash on the production line in a parallel manner and a staff member is able to remove the completely glazed window sash at the end of the processing procedure. No further user intervention is required during the production", explains Alan Levin whilst describing the main advantage of the integrated window production. On the side of the sash’line that processes the window sashes, the SashDri™ applicator precisely inserts desiccant into the respective recess of the profile via a circumferential desiccant matrix. The SashSeal™ applicator then coats the profile webs from both sides with reactive hotmelt in a circulation process. At the same time, a glass plate washing machine located on the glass processing side of the line ensures clean and dry glass plates. The result of the cleaning process can be subsequently checked with the aid of a visual inspection system.

A swivelling conveyor connects the two production sides and ensures that the cleaned glass plates and the corresponding window sashes – that have been prepared with desiccant and adhesive sealant – are both transported into the press. In the final stage, the press that was exclusively developed for the sash’line merges the glass and profile into a window sash and simultaneously fills the unit with inert gas during this process. The field of application of the sash’line are window systems that are to be directly glazed such as the Sashlite™.

Alan Levin and the SashSeal™ applictor of his sash'line

sash’line receives Crystal Achievement Award

In September 2010 Bystronic glass received the „Crystal Achievement Award“ of the American glass magazine „Window & Door“. A panel of judges representing all segments of the industry crowned the sash’line being the most innovative machine in the field of glass processing / insulating glass production. The award recognizes significant innovations and achievements in window and door technology, manufacturing and marketing.

Add new comment