Date: 12 August 2015

Planned is the construction of a 1.200m² large machine hall and a 950m² office wing. The future exhibition and training hall with state-of-the-art plants serves for presentation purposes as well as for the training of customers and the service technicians of all subsidiaries.

„With its finger on the pulse of the time, the new service and training center which is equipped with the latest infrastructure meets the global requirements of our customers”, explains Peter Rattinger – Head of the Service Department. The completion is planned until the end of 2015 in order to enable a complete use of the new service and training center already in January 2016.

.jpg)

About LiSEC

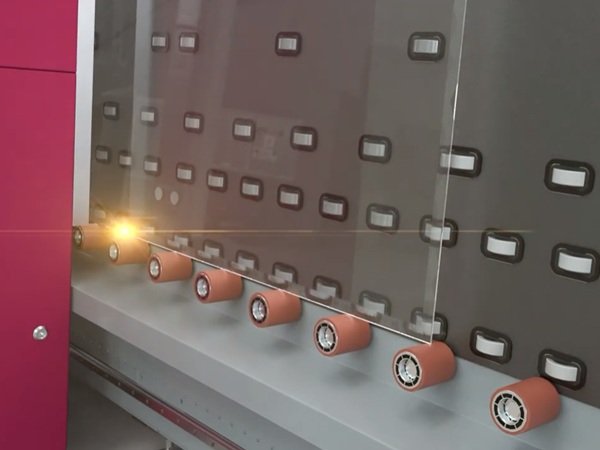

LiSEC based in Hausmening/Amstetten is a globally active group which has been offering innovative individual and overall solutions in the field of processing and refining of flat glass for more than 50 years. LiSEC’s service portfolio comprises machines, automation solutions and services. In 2013, the group with its approximately 1500 employees and more than 20 locations generated an aggregate turnover of about 200 million Euros at an export rate of more than 90 percent. LiSEC develops and produces glass cutting and sorting systems, individual components and entire production lines for the production of insulating and laminated glass as well as machines for the processing of glass edges and tempering systems. With a reliable technology and intelligent automation solutions, LiSEC sets standards in terms of quality and technology and makes a substantial contribution to the success of its customers.

Add new comment