Date: 22 September 2009

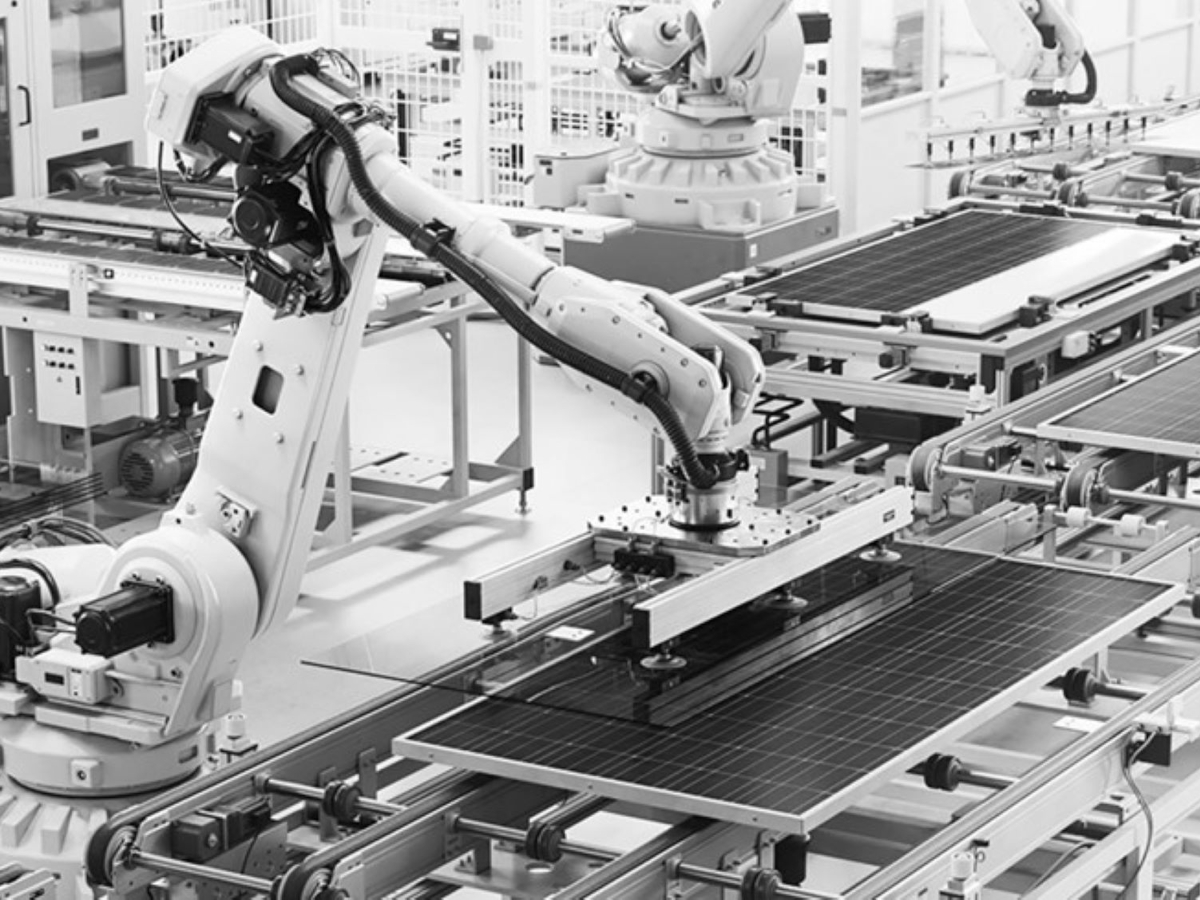

By increasing the efficiency and yield of solar cells, PV power can become more cost effective versus other forms of energy. “We’re working with innovative suppliers like DuPont to integrate highly customized material formulations with our leading-edge solar manufacturing systems to drive down the cost per watt of solar energy,” said Charles Gay, president of Applied Solar at Applied Materials. “By using our Baccini back-end systems equipped with Esatto Technology™ and DuPont™ Solamet® photovoltaic metallization paste, customers can achieve the precision alignment, repeatability and process control that enables successful multiple printing.” “This collaborative technology will optimize the efficiency of solar cells and meet the needs of the market by ultimately lowering total system cost,” said Marc Doyle, global business director – DuPont Photovoltaic Solutions. “By working together, we can deliver photovoltaic materials and technologies to our customers better and faster.” The collaboration reflects DuPont’s recently announced commitment to focus on meeting four emerging global trends, one of which is decreasing dependence on fossil fuels. Photovoltaic metallization pastes are screen-printed onto the surface of solar cells in a pattern of grid lines which collect electricity produced by the cell and transport it out. To maximize efficiency in the solar cell, the multiple printing technology will reduce the shadowing effect of wide grid lines on solar cells and improve electrical conductivity. Applied Baccini Esatto Technology™ together with DuPont™ Solamet® photovoltaic metallization pastes enables narrower and taller grid lines to be precisely printed in two or more layers. In addition to demanding precise alignment of the patterning system, multiple printing requires the paste to be finely tuned to perform consistently during all printing passes.DuPont and Applied Materials, Inc., are collaborating to advance multiple printing technology expected to increase the absolute efficiency of crystalline silicon (c-Si) photovoltaic (PV) solar cells. By increasing the efficiency and yield of solar cells, PV power can become more cost effective versus other forms of energy.

“We’re working with innovative suppliers like DuPont to integrate highly customized material formulations with our leading-edge solar manufacturing systems to drive down the cost per watt of solar energy,” said Charles Gay, president of Applied Solar at Applied Materials. “By using our Baccini back-end systems equipped with Esatto Technology™ and DuPont™ Solamet® photovoltaic metallization paste, customers can achieve the precision alignment, repeatability and process control that enables successful multiple printing.”

“This collaborative technology will optimize the efficiency of solar cells and meet the needs of the market by ultimately lowering total system cost,” said Marc Doyle, global business director – DuPont Photovoltaic Solutions. “By working together, we can deliver photovoltaic materials and technologies to our customers better and faster.”

The collaboration reflects DuPont’s recently announced commitment to focus on meeting four emerging global trends, one of which is decreasing dependence on fossil fuels.

Photovoltaic metallization pastes are screen-printed onto the surface of solar cells in a pattern of grid lines which collect electricity produced by the cell and transport it out. To maximize efficiency in the solar cell, the multiple printing technology will reduce the shadowing effect of wide grid lines on solar cells and improve electrical conductivity.

Applied Baccini Esatto Technology™ together with DuPont™ Solamet® photovoltaic metallization pastes enables narrower and taller grid lines to be precisely printed in two or more layers. In addition to demanding precise alignment of the patterning system, multiple printing requires the paste to be finely tuned to perform consistently during all printing passes.

Add new comment