Date: 8 May 2006

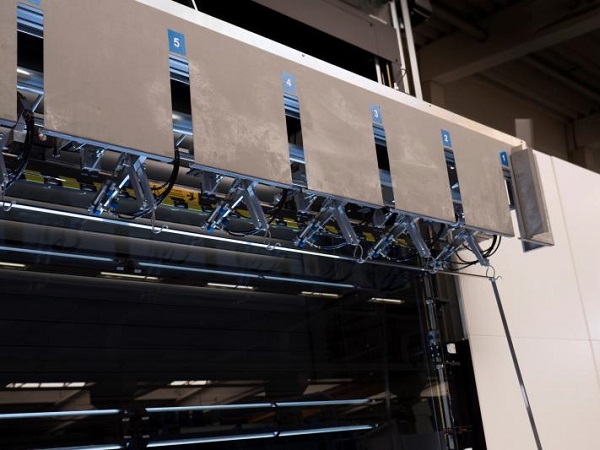

The Easy-Lift-CNC is the first handling device that can be used to put the glass sheets directly in the machine bed.

Compared to standard loading methods, the utilisation of the Easy-Lift-CNC not only results in significant time savings: according to product developer Horst Wiedemann, the new loading concept is also considerably more gentle on materials.

"With our Easy-Lift-CNC the glass sheet is taken from the glass rack and moved in via the integrated slide rails into the CNC processing centre where it is deposited directly into the machine bed. As a consequence, we are able to largely exclude damage to work pieces caused by glass dust and glass splinters as they commonly occur on loading tables.

Up to now, glass finishers loading CNC processing centres that are closed at the top have had to make use of an interstation. The glass plates are generally firstly loaded onto an adjacent, mobile roller table before being loaded into the CNC centre by hand. This interstation is now no longer required, thanks to the new vacuum lifting device from Bystronic.

The Easy-Lift-CNC is carried by a lightweight craneway system which may also form part of the scope of supply. However, the handling device can also be integrated into an existing double bridge crane system. A standard 7 to 8 bar compressed air connection is sufficient for operation.

The benefits of the established Easy Lift series also guarantee optimal handling characteristics with this special product. The Easy-Lift-CNC is mostly made of aluminium. The low own weight in combination with rigid guidance and stepless adjustable hoisting tube mean that it is possible for one operator to move also large glass formats and position them precisely.

The Easy-Lift-CNC is suitable for glass sheets with dimensions of 2.30 metres x 3.20 metres and a maximum weight of 150 kg.

Further information can be obtained from Bystronic technology centre Armatec.

Add new comment