Date: 2 August 2011

With the sharp increase in demand for photovoltaic applications, particularly in recent years, the requirement for suitable glasses and the automatic processing of them has also significantly increased. The handling and processing of glass are important process steps for the photovoltaic industry where it can learn and profit from the tried and trusted applications from the glass industry. For instance, the Bystronic glass Group, one of the leading providers of system solutions for machines and plants for the processing of architectural and automotive glass, specifically contributes its experience and technologies for applications in the solar industry – in areas for example, such as loading, storage systems and especially in the field of glass cutting.

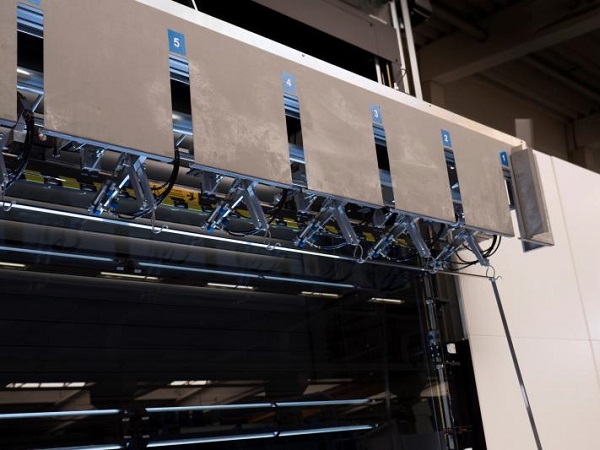

The establishment of cutting centres that are exclusively oriented towards the processing of special glasses is an emerging trend in the photovoltaic industry. These centres have to economically and efficiently process all common glass types and sizes to some extent with their highly sensitive precoating. For the start of the production chain, Bystronic glass offers flexible loading systems that are available for all common raw glass formats with individual stock dimensions and ensure a safe glass loading. The cutting of the glasses to the desired dimensions with automated X, Y and Z breaking as well as subsequent rotation and turnover of the glasses depending upon the coating, then follows.

Bystronic glass cutting convinces with flexible equipment

Bystronic glass rises to the high standards and requirements of these cutting centres with the speed’cut, the most recent new generation machine presented for glass cutting. The modular concept enables the customer to appropriately configure the machine to their individual requirements in the project planning stage, for example based upon the cutting table: Large glass format sizes (7000 x 3300 mm) are processed with a single cutting bridge whereas small formats (2130 x 1600 mm) are achieved with two cutting bridges operating in parallel. "One of the excellent properties of the speed’cut – as its name already implies – is the speed," says Lorenz Buri, head of sales for machines and applications for the processing of architectural glass as well as for the solar industry. The cutting head moves at a speed of up to 300 metres per minute and accelerates at up to 6 metres per square second. Lorenz Buri explains: "As a result, our customers obtain extremely short cycle times and are in the position to process their cutting plans as quickly as possible."

Quick, precise and low-maintenance thanks to linear drive technology "The speed’cut belongs to a new generation of machines that work with a modern linear drive technology. Previous common and maintenance-prone machine parts such as racks and sprockets are no longer necessary. This reduces maintenance outlay, replacement part costs as well as possible downtimes," Lorenz Buri clarifies. The cutting bridge with its lightweight construction offers a further potential for saving: thanks to its honeycomb structure, the bridge is significantly lighter than conventional cutting bridges, can be started and accelerates more easily, therefore it reduces energy consumption.

Despite the speed and level of saving, precision is a decisive topic, especially in the solar industry. The customer obtains highly precise results with regard to the desired glass dimensions thanks to the measuring system used on the speed’cut. At the same time, this reduces the necessary grinding tolerances to a minimum. The requirement for manual interventions by an operator is reduced substantially thanks to its automated tool changer and the establishment of multiple cutting oil circuits for various glasses.

Software with an ultra-modern operating concept – even online

The controls connected to the network simplify the preparation and monitoring of the production on the speed’cut: various cutting plans can be loaded onto the machine with the aid of the ByFlow software. Furthermore, it records production data complete with details concerning cut glass plates, information concerning the wear of cutting wheels and details concerning cutting parameters as well as the operating state of the unit. The head of sales explains: "The software for quality control also registers important data, such as which photovoltaic glass was cut with which raw glass for example. A continuous traceability is guaranteed as a result." The graphical interface of the touch operated screen as well as the tailored user procedures support the user-friendly operation of the unit.

In combination with the ByStore storage management software, the user also obtains online information concerning the content of the glass warehouse complete with details concerning the glass amount, glass dimensions and the lot numbers of the raw formats located in the warehouse. The integration of visual inspection systems guarantees the panel quality in each phase of the value creation chain and prevents additional costs over the course of the entire processing procedure.

In order to track the individual photovoltaic modules online, the ByLine software is available together with the machine: the online tracking begins with the cutting of the raw glass. The data is then constantly sent to each production process step or to the subsequent conveyor unit. For example, as a result, an emptying of the conveyor units when starting up the unit at the beginning of the shift is no longer required.

Conclusion

Lorenz Buri summarises: "The mentioned properties underline that the speed’cut is an extraordinary cutting table for glass that is used in the preparation of the insulating glass and is also convincing within the solar industry– with properties such as economy, flexibility, constant availability, high product output and reliability."

www.bystronic-glass.com

About Bystronic glass

Bystronic glass is the most competent and reliable partner for services, machinery, plants and systems in the glass processing sector. Bystronic glass supplies its well-proven machine technologies also in important areas of the photovoltaic industry. This includes preprocessing and front-end and back-end solutions. Bystronic glass is an international brand with globally operating companies that support their customers on site and through own sales and service companies. Since 1994, Bystronic glass is part of the Conzzeta AG, a renowned Swiss industrial holding company.

Add new comment