Date: 3 February 2009

As well as the TPS® applicator for encapsulating filmless thin-layer modules, visitors at the approximately 150-sqm stand F4 in hall C2 will also be able to view the Glass Plate Washing Machine GW-D, which is being used in the production of thin-layer modules and in the field of wafer-based modules. .jpg)

Proven machine technology with new application

Over ten years ago, Bystronic Lenhardt GmbH developed a process, during which the metallic spacer frame normally used in the insulating glass production between the two lites was replaced by a thermo plastic spacer. Due to its great flexibility and its excellent sealing properties, this TPS® material is ideally suited for use in the photovoltaic industry:

a) For encapsulating filmless thin-layer modules

The TPS® applicator can generate spaces between 0.7 and 6 millimetres. Opposed to vacuum lamination, this encapsulating method uses considerably less energy as it operates without any heating or cooling. Depending on the module size, the cycle times are approximately 30 to 45 seconds. .jpg)

b) For sealing of semi-conductor systems

TPS® is suitable for sealing of modules based on copper-indium- diselenide (Cis) or copper-indium-gallium-diselenide (Cigs) and cadmium telluride (CaTe). The machine is available in both horizontal and vertical options. Depending on the film thickness, the application thickness of the thermo plastic spacer® varies between 0.5 and 0.76 millimetres - with the most precise application. Integration into complete back-end lines and existing plants is possible. Thanks to a dual drum pump system, the machine is able to operate 24 hours a day, seven days a week.

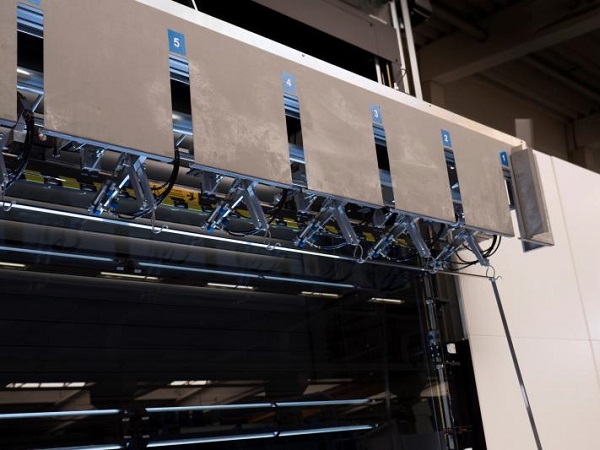

Perfect performance for a clear view

The Glass Plate Washing Machine GW-D is environmentally friendly with its unique energy-saving water treatment. A gravel aggregate filter is used in the production of thin-layer modules as well as in the field of wafer-based modules. The machine, made entirely of stainless steel, is also available as an integral part of a back-end line or as a stand-alone solution which is supplemented by a robot for supply and discharge. .jpg)

The facts:

- continuous washing of different glass thicknesses

- up to 15 millimetres - three seperate brush pair drives

- chainless brush and conveyor drives

- infinitely adjustable conveying speed

- seperate washing an rinsing zone

- alternating directions of brush rotation

- for optimum cleaning effect

- vertical design

- can be extended by adding a scanner for

- quality assurance

Add new comment