Date: 10 January 2012

The main drawback to this method is that the diamond particles are randomly distributed throughout the segment and each individual particle, therefore, is not subjected to the same cutting force throughout the cutting operation.

2.Where particles are too closely clustered, the leading particles do most of the ‘work’ whereas the following ones are not contributing fully to the cutting mechanism. This leads to premature pullout of the leading particles. Similarly, where large gaps between particles exist, the bond is being exposed to the workpiece which leads to erosion of the bond.The overall effect on blade performance was lower tool lives and slower cutting speeds.

3.Ideally, diamond particles should be evenly distributed throughout the bond which means they are all subject to the same cutting forces and the segment is operating at its optimum efficiency.Up till now this has only been possible to achieve by using time consuming manual labour - a situation which is clearly unacceptable in mass production manufacture.

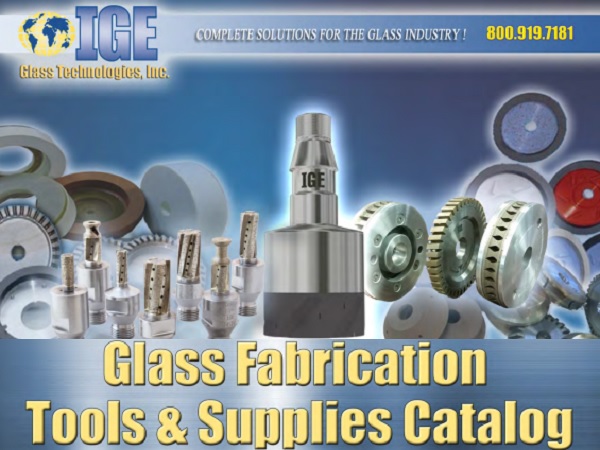

4.This situation has now changed though with a new development called ARIX – an automatic array system of segment

5.The Manufacturer is Hangzhou JDR DIAMOND TOOLS CO., LTD.

Add new comment