Date: 13 September 2007

It is super wearability and strong strength but elastic. The metal compounds allow super cutting ability. The ultra rigidity allows long lasting with high grinding efficiency.It is extensively used in vertical edging machine and horizontal double edging machine. Mostly it is cup wheel.

œ 10S - When 10S comes in contact with water coolant, its surface becomes soft allowing the cutting material and cerium oxide resulting in excellent grinding and polishing capabilities. The elasticity allows the wheel in full contact with the whole glass edge surface giving thoroughly polishing but meanwhile, allowing easy discharging of polishing scrap leaving no flaw on glass. It could also reduce pressing pressure and thus, avoiding burning. The cerium oxide give excellent bright satin finish.

œ BD - The elasticity of BD allows the wheel in full contact with the whole glass edge giving thoroughly polishing but meanwhile, allowing easy discharging of polishing scrap leaving no flaw on glass. It could also reduce pressing pressure and thus, avoiding burning. Thanks to its rigidity, the shape shall not deform nor crack despite of glass edge cutting defect, machine vibration and improper operation. The fine powder gives excellent bright satin finish.

œ BK - It is compose of high molecular material with a mixture of aluminium oxide and silicon carbide etc. The high molecular material is carefully selected such that the wheel is high elastic but meanwhile, with super wearability and high strength. The metal compounds allow super cutting ability. The elasticity allows the wheel in full contact with glass edge for complete polishing in any kind of edge profile leaving no flaw on glass. Thanks to its rigidity, the shape shall not deform nor crack despite of glass edge cutting defect, machine vibration and improper operation.

œ X5000 - X5000 is a subsitution of felt wheel with cerium oxide powder. When X5000 gets in contact with water coolant, the cerium oxide will slowly detach from the wheel and mix with water giving the glass excellent clarity. X5000 mostly comes with cup wheel. It is always used in the last step of polishing. The common edge processing is to use firstly metal bond diamond wheel, then secondly resin bond diamond wheel, thirdly 10S or 9R and finally X5000 wheel.

œ Engraving / grooving - The elasticity allows the wheel in full contact with glass for complete polishing in any kind of grooving profile leaving no flaw on glass and thus, giving remarkable satin finish with the extra help of fine polishing powder. Thanks to its rigidity, the shape shall not deform nor crack despite of glass edge cutting defect, machine vibration and improper operation. The common edge processing is to use firstly metal bond diamond wheel, then secondly resin bond diamond wheel and finally engraving wheel.

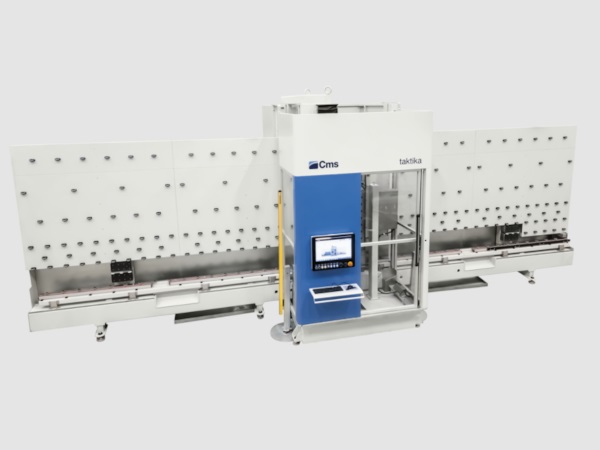

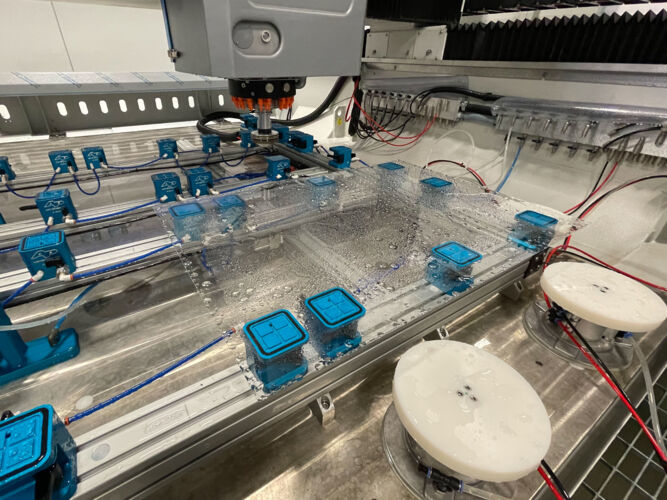

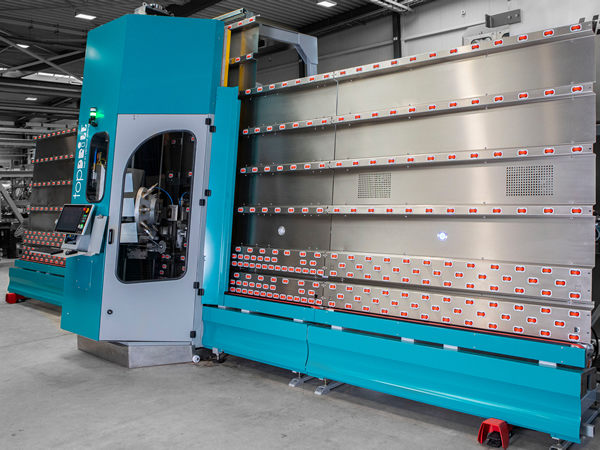

Our polishing tools are applicable for manual, semi-automatic, automatic and CNC machines.

If glass polishing is a headache to glass fabricator when polishing wheels are choosen improperly, our series of polishing wheel would be your Panadol.

Add new comment