Date: 11 February 2015

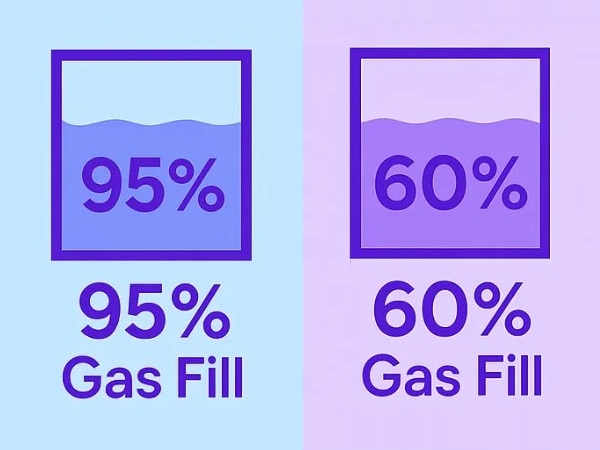

With 30 years’ experience in the glass industry, Allenby boasts a wide product range from replacement greenhouse glass and cut to size mirrors, to made-to-measure double glazed sealed units for windows and doors.Quality is key .jpg) and the company gas fills using Argon for its great insulation properties, and has recently streamlined its production process thanks to the purchase of a Smartfill 2 machine from Inagas.

and the company gas fills using Argon for its great insulation properties, and has recently streamlined its production process thanks to the purchase of a Smartfill 2 machine from Inagas.

The Smartfill 2 is an Argon gas filling machine with 250mm touch screen controls, and the latest technology to enhance control and improve productivity, including the Smart Start filling lance, which provides the operative with control, without having to return to the machine. The machine is capable of 30 litres per line per minute and is designed for dual line production – making it ideal for enhancing productivity.

Dave Harris, Owner of Allenby Glass comments: “We are really pleased with the Smartfill 2, it is really simple to use and has helped smooth our IGU production process no end. We have always made it our business to ensure that everything leaves our factory at the highest standard and so we only use top quality products from companies who lead their field. When it comes to service we are also very happy with Inagas, if we ever need a part we can send it straight back and always get a prompt response.”

Add new comment