Date: 9 January 2008

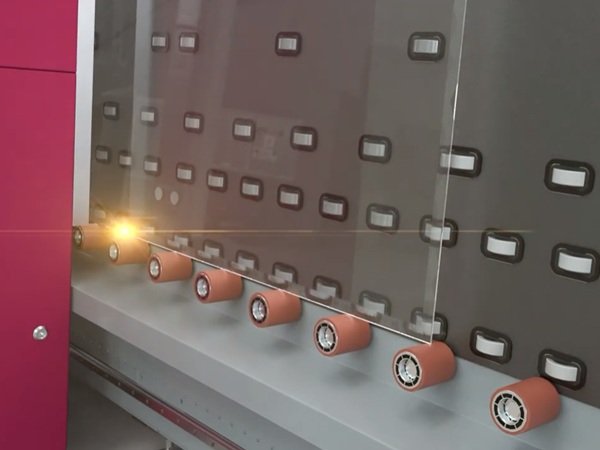

Standard Accu-Cure units can accommodate glass panels of varied thicknesses and up to 102 inches (259 cm) wide, with larger capacities available through custom orders. Accu-Cure’s computer-designed cooling system safely cures all types of UV inks and coatings while minimizing the heat transmitted to the substrate.

“The Accu-Cure line is another highly advanced component in our complete modular system for glass makers creating decorative or other printed glass products,” said Michael Green, A.W.T. president. “For example, by adding our Accu-Print High-Tech V™ line of screen printers, cooling units and additional conveyor modules, glass producers can easily configure a complete largeformat glass-decorating operation. Equally important, we can custom design any of the modules to meet a user’s specialized needs.”

Drawing on more than 30 years' experience in UV curing technology, A.W.T. combines performance with safety in the Accu-Cure UV curing unit. An operator can adjust gate height on the curing head module to accommodate varied stock thicknesses and to eliminate light leakage. The operator also may adjust the UV lamp output from 100 to 300 or 400 watts, depending on the Accu-Cure model, to meet production requirements, conserve energy and prolong lamp life. In addition, the Accu-Cure™ Ultraviolet Curing Unit has an ozone removal system to safely vent ozone and hot air out of the working area.

In addition to the complete conveyorized UV curing system with exhaust, the Accu-Cure™ is also available system as a retrofit package consisting of a curing head and light guard assembly. Also available are additional conveyor sections, sold in one-foot (30 cm) increments, as well as standalone conveyor units. Accu-Cure models include the standard configuration, the Accu-Cure Compact UV and the Accu-Cure 3-D.

Add new comment