Date: 1 June 2016

The company’s glass wafers and substrates serve as key materials in the fields of IC packaging, radio frequency (RF) components, and micro-electromechanical systems (MEMS). SCHOTT is presenting its industry-leading thin and ultra-thin glass wafers, and sheets for semiconductors and optoelectronics, at the Electronic Components and Technology Conference (ECTC) from May 31 to June 6 in Las Vegas (booth #220).

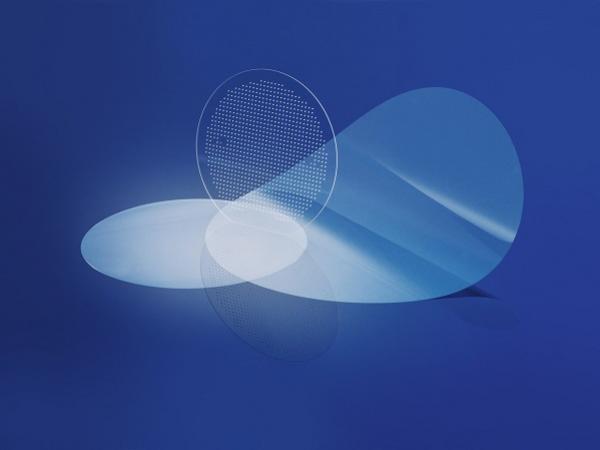

Backed by more than 130 years of experience in developing and manufacturing specialty glass, SCHOTT’s broad portfolio of glass wafers and substrates is known for its chemical and thermomechanical properties and surface qualities. The wafers and substrates are available in different sizes (wafer diameters up to 12 inches; sheet sizes up to 510 x 510 mm2) and thicknesses (from 1.1 mm down to ultra-thin 25 µm). Additionally, SCHOTT offers extensive application support in the field of handling technologies and formation of glass wafers with through glass vias (TGV), which cover a wide spectrum of feature sizes.

.jpg)

SCHOTT’s photo-sensitive FOTURAN® II glass wafers can be structured and processed in three or four steps: UV-exposure, tempering, etching and ceramization. Photo: SCHOTT

“With these technologies, SCHOTT can support the emerging ‘More-than-Moore’ trends throughout the electronics industry,” said Dr. Rüdiger Sprengard, Director New Business Ultra-Thin Glass at SCHOTT AG. “Ultra-thin glass wafers and substrates are enabling consumer electronics to be even thinner, and help make possible the high-performance computing necessary for applications like self-driving cars. Because of the versatility and unique properties of these materials, the engineering and design possibilities stretch far beyond the traditional electronics and into new industries.”

Main Photo: SCHOTT’s thin and ultra-thin glass wafers and substrates are made of different materials in sizes up to 12˝ with different surface qualities and customized features. Photo: SCHOTT

SCHOTT recently expanded its wafer portfolio with FOTURAN® II, a photo-structurable glass that is significantly more advanced in quality, such as material homogeneity, than its 30-year-old predecessor. The material’s unique properties enable high aspect ratio and small feature sizes in RF components and MEMS systems. FOTURAN® II wafers can be structured and processed in three steps: UV-exposure (with standard lithography equipment, but without the use of photo-resist), tempering, and etching; additional ceramization is an option when higher temperature stability is required.

Enabling innovation with customized processing

In addition to continuously growing its materials portfolio for the electronics industry, SCHOTT also strives to optimize and expand its processing technologies. SCHOTT often works with customers and a network of partners to develop application-specific and customized solutions for complex manufacturing processes.

For example, while developing laser structuring technologies for thin and ultra-thin glass, SCHOTT established an ultrasonic lapping process for the coarse structuring of mass produced glass wafers featuring tight tolerances.

“Superior materials, like ultra-thin glass wafers, give engineers the ability to pack more power into smaller forms,” said Sprengard. “The next innovations in semiconductor and optoelectronics technologies, such as MEMS and driverless car components, are made possible with specialty glass. These materials are helping create new innovations and opportunities across many industries because of their chemical properties and strength.”

Further information:

http://www.us.schott.com/advanced_optics/english/products/wafers-and-thin-glass/glass-wafer-and-substrates/glass-wafer-and-substrates/index.html

http://www.us.schott.com/advanced_optics/english/products/optical-materials/thin-glass/foturan-2/index.html

FOTURAN® is a registered trademark of SCHOTT AG

About SCHOTT

SCHOTT is a leading international technology group in the areas of specialty glass and glass-ceramics. The company has more than 130 years of outstanding development, materials and technology expertise and offers a broad portfolio of high-quality products and intelligent solutions. SCHOTT is an innovative enabler for many industries, including the home appliance, pharmaceutical, electronics, optics, automotive and aviation industries. SCHOTT strives to play an important part of everyone’s life and is committed to innovation and sustainable success. The group maintains a global presence with production sites and sales offices in 35 countries. With its workforce of approximately 15,000 employees, sales of $2.24 billion were generated in fiscal year 2014/2015. us.schott.com

600450

600450

Add new comment