Date: 21 March 2011

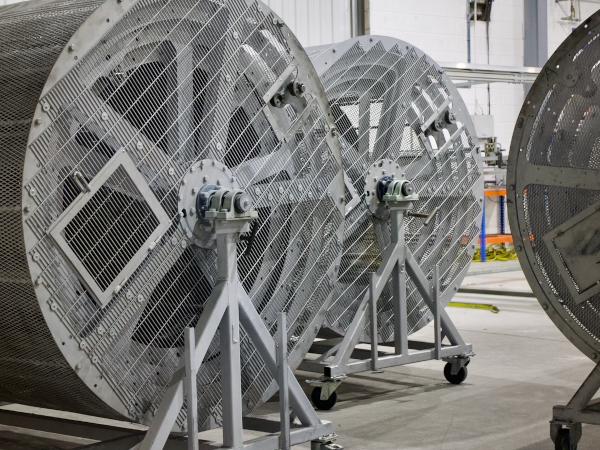

Therefore a complete revamp of the product and equipment for manufacturing the same has been invented and is now available under license for manufacturers to make their own foam spacer in house.  Glasslam has developed a fully inline spacer manufacturing system that uses less than ten percent of the energy and labor costs of the old, outdated methods. By computer control and patent-applied technology, sizes of spacer can be changed in seconds with no down time. Glasslam will supply desiccated silicone pellets and adhesives to the licensees.

Glasslam has developed a fully inline spacer manufacturing system that uses less than ten percent of the energy and labor costs of the old, outdated methods. By computer control and patent-applied technology, sizes of spacer can be changed in seconds with no down time. Glasslam will supply desiccated silicone pellets and adhesives to the licensees.

Glasslam will utilize this process in high volume at its own facilities and continue to produce and supply Air-Tight S and Air-Tight T, the industryʼs highest quality, highest desiccant, and most durable warm edge foam spacer products to customers all over the world.

There are videos and plant tours available for this new concept. Several orders are already in the pipeline, and the new system will be exhibited at future worldwide industry events, including Glasstec Dusseldorf in 2012.

Glasslam, based in Pompano Beach, FL is a world leader in laminated glass technology and quality window components.

For more information about Glasslam, please visit www.glasslam.com or call (954) 975-3233. Air-Tight™ is a trademark of Glasslam N.G.I., Inc. 1601 Blount Road, Pompano Beach, FL 33069 (954) 975-3233 FAX (954) 975-3225 www.glasslam.com

Add new comment