Date: 15 February 2008

This is a huge time saver.”

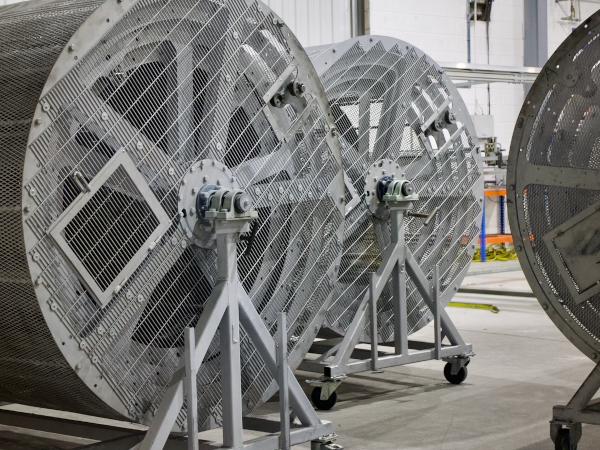

E-Z RAD is a vertical work station developed through a partnership between Edgetech I.G. and Nupro Products, Inc. First introduced in 2007, E-Z RAD drastically reduces production time for starburst, sunburst and combination patterns with up to seven spokes. The entire system is made up of three main components, including the E-Z RAD table, specially engineered muntin clamping rings and Edgetech’s IntelliClip™ muntin end clip technology.

Other benefits of the E-Z RAD system include:

• Reduced time and material waste

• Reduced application time

• Precise muntin placement

• Maximum desiccant activity inside the IG

• Compact design for easy mobility (24” wide x 96” long x 84” high)

• Contamination prevention (grids can be assembled before glass is washed)

“The ability to install grid patterns on unwashed glass is a great advantage of the E-Z RAD system because installers do not need to worry about smudges and fingerprints,” Miller said. “By lessening the number of hands on washed glass, you are lessening the chances for contamination of the end product.”

Edgetech provides free technical training with E-Z RAD. The system is easy to install with no assembly, power or air required. In addition to the 60 standard patterns available for E-Z RAD, custom pattern capabilities are also available.

Add new comment