Date: 15 May 2008

SCHOTT Igar Glass in Indonesia is the pharmaceutical packaging center of SCHOTT forma vitrum in Asia. It ranks as the largest manufacturer of primary pharmaceutical packaging products in Southeast Asia and mainly supplies its products to Asia and Australia. The site was built in 2002 and produces around 750 million ampoules, vials and pipettes per year.

The “TopLine department” in Indonesia produces tailor-made product solutions for the highest requirements. The state-of-the-art manufacturing lines are equipped with the latest technology and provide six-sigma quality for dimensional parameters and zero defects for critical cosmetic aspects. High quality standards are assured with ISO 9001:2000 and full compliance with GMP (Good Manufacturing Practice). Quality assurance is not dependent on human inspection but relies on sophisticated visual inspection technology which is far more reliable.

The Automated Inspection System (AIS) by SCHOTT forma vitrum is a proprietary, highly sensitive visual inspection technology, developed in close cooperation with a leading Swiss university over more than a decade. It assures the reliable classification of smallest defects by type, size and even the position of the defect on all key surfaces of the container. AIS is a validated and fully integrated system for inline process control and optimization.

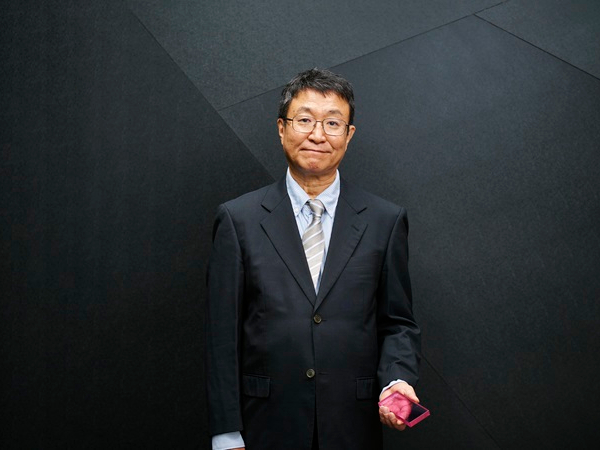

To ensure that the demands of the exigent Asian customers are understood and executed correctly, Hiro Maruyama, Quality Manager from Japan, was hired. “With the support of a specially-trained team”, says Maruyama, “we will ensure consistently high quality, stable processes and a service philosophy oriented towards Japanese business practices.”

1.909 characters

SCHOTT Pharmaceutical Packaging is one of the world’s leading suppliers of parenteral packaging for the pharmaceutical industry. More than 500 production lines in 11 production sites worldwide produce more than 6 billion syringes, vials, ampoules, cartridges and special articles made of tubing glass or polymer. Excellent raw materials, state-of-the-art manufacturing, the use of the latest technologies, continuous research and development combine to enable the development of innovative product solutions that meet the high demands of their customers. The back-up possibilities offered by production sites situated all over the world provide flexibility, reliability and security to the partners. All production sites of Business Segment SCHOTT Pharmaceutical Packaging operate in a GMP environment and the products comply with the international standards USP, EP and JP.

SCHOTT is an international technology group that sees its core purpose as the lasting improvement of living and working conditions. To this end, the company has been developing special materials, components and systems for nearly 125 years. The main areas of focus are the household appliances industry, pharmaceuticals, solar energy, electronics, optics and the automotive industry. The SCHOTT Group is present in close proximity to its customers with production and sales companies in all its major markets. The Group’s approximately 16,700 employees generate worldwide sales of approximately 2.1 billion euros. The company's technological and economic expertise is closely linked with its social and ecological responsibility. The parent company of the SCHOTT Group is SCHOTT AG, whose sole shareholder is the Carl-Zeiss-Stiftung (Foundation).

Add new comment