Date: 18 September 2014

Porous glass is an often unsung hero in fields as diverse as medicine, aerospace, defense, and oil and gas.

The glass is created through a special process in which borosilicate glass is melted, rapidly quenched, and then phase separated in a carefully controlled environment. The method triggers separation of individual glass components, and creates a sodium borate phase and a silicate phase. At the end of the process, special chemicals dissolve the sodium borate phase to yield an interconnected microstructure with open porosity — known as porous glass.

This newly created glass boasts high chemical and mechanical stability. Additionally, since the material consists of 95-97 percent silica, it has a low thermal expansion coefficient. The thermal resistance is so great, in fact, that the glass is used as a heat-resistant coating on spacecraft. It’s increasingly used in electrode junctions, desiccants, coatings, chromatography, and substrate separations.

With the help of Pennsylvania State Senator John Blake and State Representative Mike Carroll, and local Luzerne County and Duryea Borough officials, SCHOTT obtained funding from the state of Pennsylvania that, combined with SCHOTT’s significant investment, facilitated the commercialization of the production of SCHOTT’s CoralPor high-performance porous glass in Duryea, Pennsylvania.

To thank the legislators and the community for their continued support, SCHOTT was joined by U.S. House of Representatives Congressman Matt Cartwright at a SCHOTT-hosted event. State Senator Blake and State Representative Carroll were joined by various members of the local community and Chamber of Commerce at the Duryea facility to highlight the plant’s new production capabilities and showcase SCHOTT’s commitment to job stability and growth in the region. The event was a great success, but in case you missed it, here’s a picture recap of the day’s activities.

.jpg)

CoralPor nanoporous glass has a wide range of applications.

.jpg)

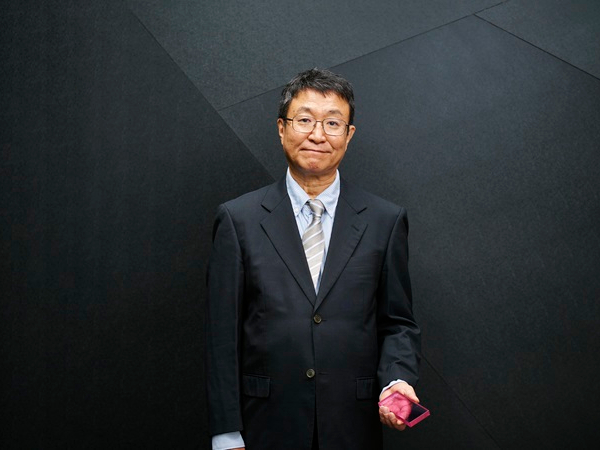

Dr. Bill James, Supervisor of Materials Development at RD for SCHOTT North America, Inc., presents CoralPor nanoporous glass and its broad spectrum of applications.

.jpg)

Shown from left to right: Brianne Morgan (Research and Development Engineer II at SCHOTT North America, Inc.), State Representative Mike Carroll, Dr. Bill James (Supervisor, Materials Development at SCHOTT North America), Donna Sedor (Executive VP of Greater Wilkes-Barre Chamber of Commerce), Dr. Eric Urruti (VP R&D and Business Development, SCHOTT North America, Inc.), Congressman Matthew Cartwright, Ed Hart (Product Manager for CoralPor at SCHOTT North America, Inc.), State Senator John Blake, Robert Durkin (President of the Greater Scranton Chamber of Commerce), Lois Morreale (Duryea Borough Manager), Keith Moss (Mayor, Duryea Borough).

Thanks again to State Senator Blake and State Representative Carroll, and we look forward to expanding our production capabilities for porous glass in the future.

If you have any questions about CoralPor porous glass, please contact me at ed.hart@us.schott.com.

Add new comment