Date: 16 November 2007

/strong>

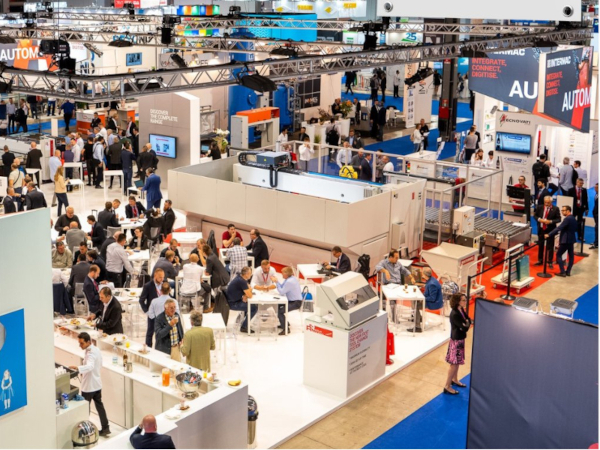

The outstanding feature of the Fiera Milano venue, the glass roof and “fair pole” designed by the architect Massimiliano Fuksas, is built entirely in glass and steel and has presented an innovative, functional, and unique example of the limitless applications and use of glass. An imposing exhibition area of over 1200 m² demonstrated For.El’s commitment to the many current and potential clients that For.El. will not only continue with innovative technology, but present its products in a precise and readily understood manner, in a comfortable and relaxing environment.

It is now 30 years since For.El. first participated in a specialised fair for glass working machines and at Vitrum 2007, the “heart and sole of For.El.” was open and visible to the entire trade.

The floor plan featured a sole entrance door giving access to a large enclosed space surrounded by ‘domestic walls’ created by the structural double-glazing line, the “Super Spacer®” line and the vertical laminated glass cutting line. As the entire range of For.El. products was on display, notably entirely and proudly produced in Italy, the clients were treated to a complete display of the latest developments and technological innovations presented during the fair.

The primary new presentation was For.El’s technical solution for a glass lamination line - “after two years of development, we have introduced this great innovation that is characterised by the combination of the most advanced technology and the best automation available today for the production of laminated glass of the highest quality. Proven reliable solutions that For.El. can personalise for every customers’ type of production demand, without exception” – this is the comment of the President Fortunato Vianello, who also emphasized one of the particular characteristics of the plant: The recognition of laminated glass for both safety and aesthetic purposes.

The demand for laminated glass of varying glass types with dimensions, shapes, and characteristics incorporating high added value (Low-E, toughened, silk-screened, painted, reflecting etc.) is easily matched and exceeded due to the For.El. plant’s unique high levels of performance, combined with extreme flexibility, especially when compared to the other current plants available on the market.

It is not surprising to note that the visitors responded with great interest to the presentation of a selection of special glass panes produced with this new plant and exhibited in front of a 2800 mm capacity autoclave present in the centre of the stand. “I am pleased to note that the glass sector of our industry continues to increasingly consider the For.El. brand as the reference for the double-glazing glass world. This leadership has matured thanks to over thirty years of experience and strong research that allowed us to supply high performance, reliable, and innovative machinery,” continues Mr. Vianello who pointed out the characteristics of the additional new releases presented at the Vitrum fair.

Featured among the many new releases were the improvements offered with the vertical cutting line for laminated glass. After 10 years since its introduction, this machinery is experiencing ever increasing demand when increased productivity, finished size precision and reliable technology is required. Important features such as: the quality of the evenly stretched PVB membrane; the precision in the cut edges of each finished glass piece; the very efficient optimisation and the level of automation that permits a single operator to autonomously manage the production of about 800-1000 m² in the eight hours. These unique features continue to be honed and improved and resulted in very high levels of interest by both existing and many new clients. This is a further demonstration of For.El’s policy of incessant research and development resulting in a continual stream of new solutions and new technologies.

In the insulating glass field, For.El. continues to present unique, proven solutions among the leading companies in its sector, easily meeting the demands of a most technological and performance oriented market with the supply of :

• the Super Spacer® automatic line, completely automatic in the application of the warm-edge spacer, gas filling and in the automatic sealing with hot-melt.

• line for structural glazed frames for buildings, extremely versatile in its ability to offer variable offsets (up to 100 mm), gas filling and automatic structural sealing, capable of executing the final sealing of the single or double interspace and staggered double-glazing glass sheet panels, with squeegee coating of the offset up to 70 mm wide.

![]() All the above is testimony to the ongoing search for solutions that can increase the competitive advantage of For.El’s. clients compared to the competition, the creation of personalised machinery and the immediate technical assistance on site through For.El. Service, are particular advantages offered by For.El. through constant growth over many years that confirms the importance of a cordial trusting dialogue and a confidential relationship with all clients. “At our house the world feels safe”.

All the above is testimony to the ongoing search for solutions that can increase the competitive advantage of For.El’s. clients compared to the competition, the creation of personalised machinery and the immediate technical assistance on site through For.El. Service, are particular advantages offered by For.El. through constant growth over many years that confirms the importance of a cordial trusting dialogue and a confidential relationship with all clients. “At our house the world feels safe”.

Add new comment