Date: 9 October 2013

SCHOTT researcher and optics expert Dr. Peter Hartmann has developed a model that allows for the very accurate prediction of the strength and service life of ZERODUR® components that are used in high stress environments, such as astronomy or microlithography, for instance. This means even higher reliability, security and efficiency for customers and applications. Hartmann was awarded the 2013 SCHOTT R&D Prize for his work.

.jpg)

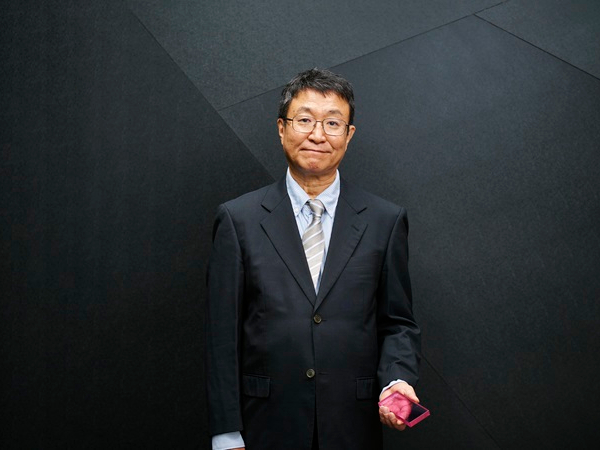

Optics expert Dr. Peter Hartmann received the SCHOTT R&D Prize for developing a model for precisely predicting the strength of ZERODUR® glass-ceramic.

Due to their strong atomic bonds, glass and glass-ceramic materials theoretically resist high bending stress. In reality, however, these capabilities deteriorate quite considerably under stress. This can be attributed to microcracks in the surface, which, if deep enough, can lead to breakage and thus complete component failure. It is therefore all the more important for developers and engineers to gain a more accurate understanding of the strength of components in more difficult applications. Ideally, the probability of failure under maximum stress is to be minimized as much as possible.

The technology group SCHOTT is capable of providing customers with detailed information on the strength and service life of mechanical and optical components made of the temperature resistant ZERODUR® glass-ceramic. Accurate predicting of component strength is possible using a new scientific approach taken by optics expert Dr. Peter Hartmann, who has been awarded the SCHOTT R&D Prize. His work proves that the conventional approach for determining the strength of glass and glass-ceramic, the so-called "two-parameter Weibull distribution," no longer suffices, rather it needs to be enhanced by a modified approach. This approach provides a minimum strength value for defined surface conditions and enables the calculation of the service life under specified stress while considering material fatigue under stress. Yet another advantage: this model reduces statistical uncertainties and allows for considerably higher mechanical stresses to be applied to ZERODUR® components than in the past.

"This work documents a high degree of scientific and technical professionalism and demonstrates the outstanding material and technological expertise SCHOTT has," explained SCHOTT Board member Dr. Hans-Joachim Konz at the award ceremony. "Furthermore, this work underscores our goal of offering benefits to our customers through our profound understanding of materials. This is thus an example of the successful link between science on the one hand and technical marketing on the other," he adds.

.jpg)

Carving out the backside of ZERODUR® creates truly lightweight mirror substrates. Thanks to up to 90 percent weight reduction and even higher strength, these lightweight mirrors are ideally suited for use in space telescopes and satellites. Photo: SCHOTT

SCHOTT is an international technology group with more than 125 years of experience in the areas of specialty glasses and materials and advanced technologies. SCHOTT ranks number one in the world with many of its products. Its core markets are the household appliance, solar power, pharmaceuticals, electronics, optics, transportation and architecture industries. The company is strongly committed to contributing to its customers’ success and making SCHOTT an important part of people’s lives with high-quality products and intelligent solutions. SCHOTT is committed to managing its business in a sustainable manner and supporting its employees, society and the environment. The SCHOTT Group maintains close proximity to its customers with manufacturing and sales units in 35 countries. Its workforce of around 16,000 employees generated worldwide sales of approximately 2 billion euros for the 2011/2012 fiscal year. SCHOTT AG, with its headquarters in Mainz (Germany) is owned by the Carl Zeiss Foundation.

Add new comment