Date: 16 March 2009

o:p>

By treating your water with a Reverse Osmosis (RO) process to remove contaminants and dissolved solids you can remove your requirement for resin and help to improve the quality of your production process.

RO is the most convenient and effective method of water filtration, forcing water through a membrane which is rated at 0.0001 micron (equals to 0.00000004 inch!). This is the technology used to make bottled water. It is also the only technology capable of desalinating sea water, making it into drinking water. Improved quality water in your glass washing machine helps to extend its service life and the quality of your finished IG units. It is ideal for processing soft coat glass and means that you don’t need demineralising resin.

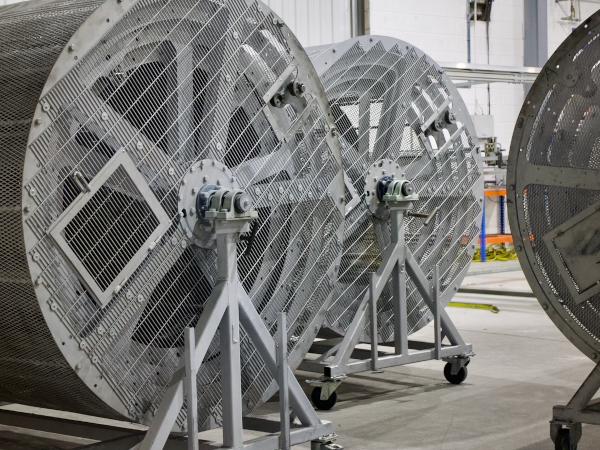

Mark Hickox, sales director at Thermoseal Group says: “The quality of water used in IG manufacturing can have a significant effect on the quality of the sealed units that you produce. With this in mind, we have manufactured a Water Purification/Treatment Plant which carries out the reverse osmosis process and is capable of feeding purified water to multiple glass washing machines. At a purchase cost from as little as £6995 + vat, if you currently use just one sack of demineralising resin per week, this machine will save you resin costs of approximately £4,000 per year. This is a significant saving and means that the machine will easily pay for itself in less than 2 years!”

For further details and specification for the Water Treatment Plant visit the Group’s website on www.thermosealgroup.com. Direct link to the machine on: www.thermosealgroup.com/machine-range.

Alternatively, call Thermoseal Group on 0845 331 3950 (International +44 121 331 3950) or e-mail sales@thermosealgroup.com and see how this supplier can help you to reduce your sealed unit and manufacturing material costs.

Add new comment