Date: 13 April 2015

Eager to share its expertise, Arkema organized the first webinar of its Web Academy on 24 March 2015.This session introduced the basic facts of the Hot End and Cold End Coating technologies. The webinar involved a presentation of some twenty minutes with commentary and explanations by our top technicians, followed by a Q&A session. It was a great success with connections from around the world.

This online training programme is open to anyone involved in the world of the glass container industry, namely glass manufacturers, bottlers, brewers, and the returnable glass industry. This first training session was part of Arkema’s Certin® T certification programme which aims to guarantee to the sector’s players an optimum standard of protection for their bottles. Upcoming sessions of the Web Academy will soon be open for registration.

Do sign up on line without delay or contact our local representatives if you require further information.

Arkema offers world-unique expertise for the protection of bottle glass:

- To glass manufacturers

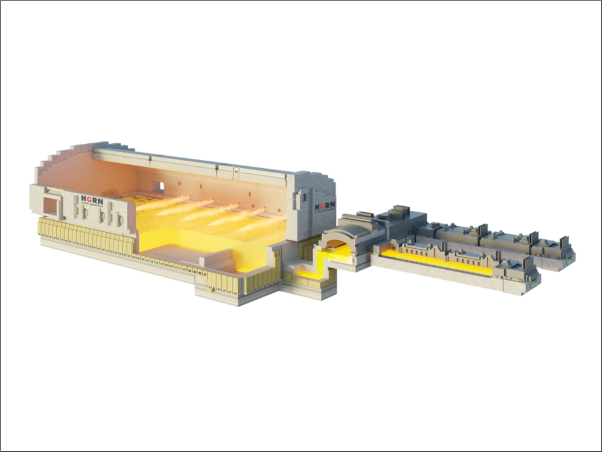

Arkema has developed hot end and cold end spray technologies with CertinTM Hood and CertinTM Spray equipment, as well as CertinTM Coat and CertinTM Top Coat coating products that provide high quality coatings, therefore making the glass tougher. This is the CertinAdvance® range

- To bottlers

The Kercoat® and Opticoat® solutions help delay the onset of scuffing and mask it when it eventually appears. These solutions include technical support services and are supplied on the basis of turnkey installations. They afford cost savings for the maintenance of returnable bottle stocks.

Find out more

Add new comment