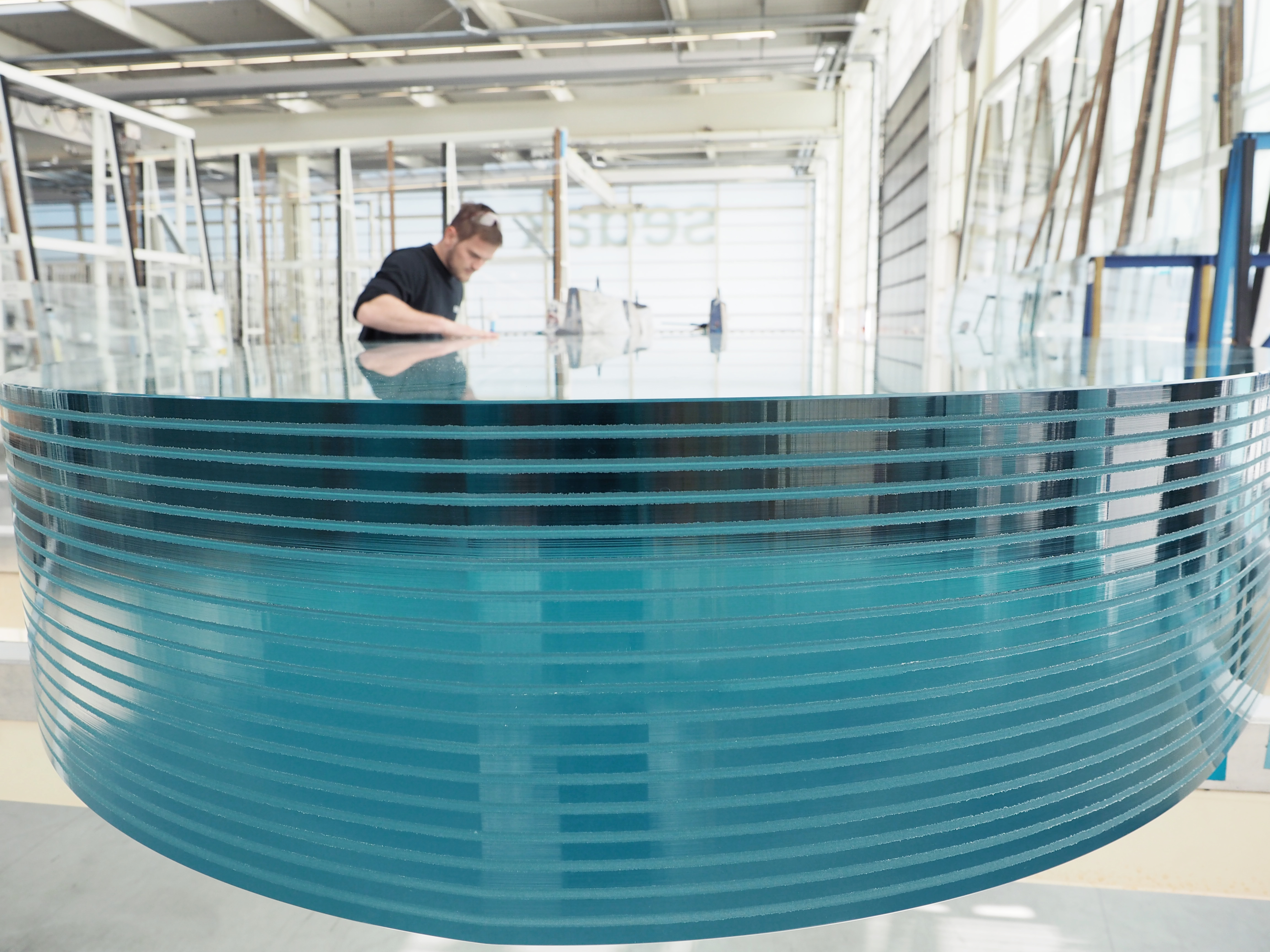

With multiple laminates of up to 12 layers, sedak safety glass shows maximum strength. Heavyweights weighing up to 8,000 kg (17,600 lbs) per pane, which are manufactured under highly accurate requirements, can resist even massive forces.

sedak VSG laminated safety glass with reliably bonded fragments of glass for a calculable residual loadbearing capacity and residual stability

sedak secusun® laminated safety glass with a solar control coating

sedak secusound® sound safety glass with a special PVB interlayer

sedak secuprotect® laminated safety glass with a highly exclusive protective function with seven safety qualities

sedak secucolor® laminated safety glass made of body-tinted safety glass, covered with colored sheeting or printed fully covered

sedak secudecor® with a partial decorative coating or a ceramic-ink digital printing

sedak GlasCobond® laminated safety glass with a SentryGlas® interlayer for exceptional stiffness and loadbearing capacity

GLY-MarineCobond® laminated safety glass with a SentryGlas® interlayer certified