Date: 22 October 2013

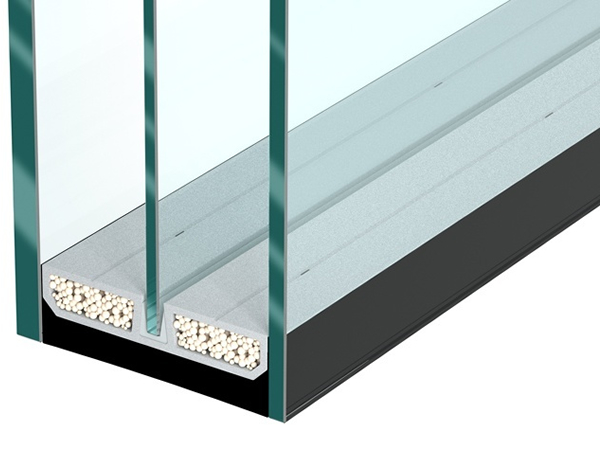

Black Pig Frame Finishing, a nationwide manufacturer and installer of glazing for green timber buildings, has developed an improved method of face applied glazing which eliminates problems including water ingress, heat loss caused by draughts and unsightly cracking around windows.Green oak is newly felled timber which has a high moisture content and takes up to five years to dry out. During this time, the cut timbers will shrink so any structure created using green oak will naturally experience movement. That means elements such as windows and doors must accommodate this movement.Black Pig’s face applied glazing solution involves cladding the entire structural glazing frame to offer protection and provide a continuous waterproof seal. Sealed units then ‘float’ to allow for movement of the frame and all weather seals are EPDM rubber to provide longevity. No silicone or other mastics, which are prone to degradation, are used and drainage is built into the system to extend the life of the sealed units.Manufacturer of the sealed units GLASSOLUTIONS ensures Black Pig can balance thermal performance with solar control and help green oak building architects manage the drying process over time.It manufactures sealed units with a Swisspacer spacer bar and argon-fill using SGG COOL-LITE SKN 174.This delivers a sealed unit with high light transmission and a very low g-value, which reduces solar gain by as much as 30% compared to standard thermally insulating glass. Importantly, this is combined with an excellent U-value of 1.1W/m2K and a high degree of neutrality both in transmission and exterior reflection.

Simon Ely, MD of Black Pig Frame Finishing, said: “Green timber buildings are extremely popular amongst architects and clients looking for a modern style of building based upon traditional craft skills with inherent ecological credentials. But the natural drying process of the timbers requires careful attention to the glazing otherwise the building will suffer fundamental problems which could prove costly to rectify.

“Our solution is proving very popular and we have now installed glazing in more than 300 buildings across the UK. Working closely with GLASSOLUTIONS, we can offer architects a proven system that moves with the building without compromise.”

More information about Black Pig Frame Finishing is available at www.blackpig.me.

Add new comment