Date: 14 May 2010

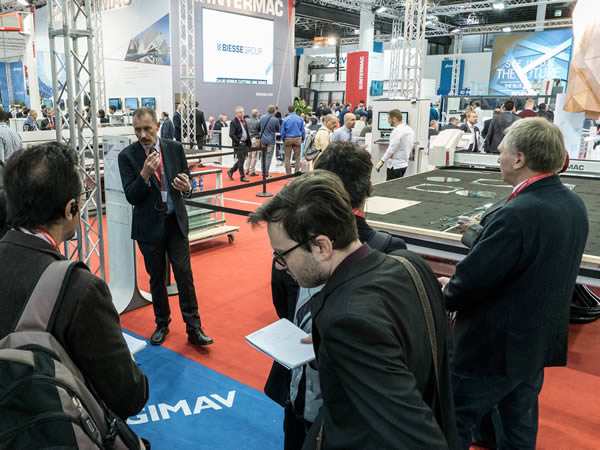

The message and the concrete results of the project extended to the graphics used on the exhibition stand.

The aim of the Green project is to produce highly technological solutions that save energy and guarantee measurable savings for the client while increasing environmental awareness. Biesse has decided to fully embrace today’s ecological sensibilities and adapt them to the corporate philosophy, progressing from a technological company to an eco-technological company, with sustainable technology that also benefits the client. Ecology is an integral part of Biesse technology and to demonstrate this concept a colorful “TECHNOLOGY” logo has been adopted which represents the fusion of the terms Technology and Ecology.

The latest generation of Biesse machines are designed to consume less energy and emit less pollution through optimization of the work processes and of CO2 emissions.

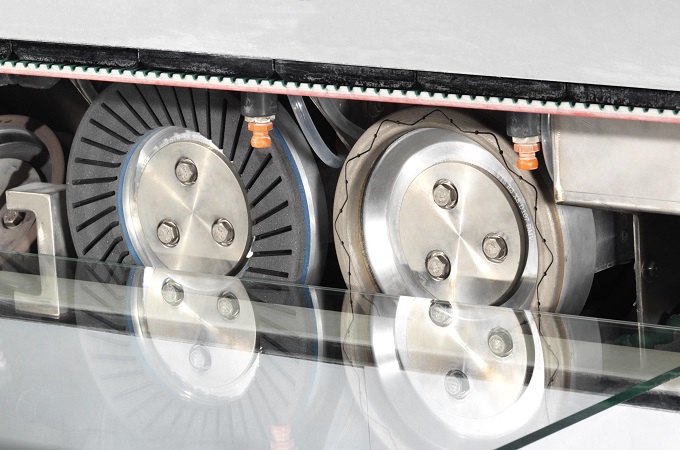

The characteristic features of the Biesse new energy saving technologies are:

- Intelligent energy management: this adjusts the machine performance to the requirements of the job in hand;

- Automatic stand-by on machines: those features not being used are automatically on standby and reduce energy consumption;

- Continuous monitoring of energy consumption: which permits better and more efficient use of the machine park;

- Energy recovery: some of the kinetic energy is recovered from the electro-spindle motor and reconverted into electricity;

- Efficient vacuum generation: only those pumps required by the job are activated;

- Dust extraction optimization: air suction is only activated on those nozzles in use;

- Compressed air interruption: the pneumatic air flow of a machine not in use is interrupted and cannot leak;

- Reduction in CO2 emissions of up to 30 tonnes per annum;

Add new comment