Date: 6 July 2009

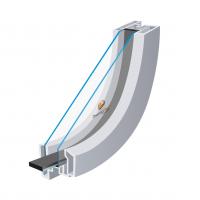

Thermobar has been engineered using thermoplastic tube and an integrated non-metallic gas diffusion barrier.Thermobar from Thermoseal Group has been engineered using thermoplastic tube and an integrated non-metallic gas diffusion barrier.

Over two years ago, Thermoseal Group set itself the challenge of starting a new UK manufacturing process to bring its nationwide customer base the most thermally efficient traditional-style spacer tube in Europe.

Having embarked on an intensive research and development project, the UK’s leading supplier of insulated glass sealed unit components and glass sealed unit manufacturing machinery, has discarded many prototypes to produce a spacer tube which has exceeded the management team’s expectations.

Thermobar is constructed using a specially formulated engineering plastic which, unlike many other warm edge spacer tubes, is designed to be used in combination with all sealant types. It bonds exceptionally well with hot melt butyl sealants which are the predominant choice of sealant for the UK market.

The face of the spacer tube has been designed with a twin line of perforation holes. This ensures that the air which expands on application of hot melt sealant can pass easily into the airspace and back into the spacer tube as it cools. This also means that the desiccant has the opportunity to work straight away, unlike some spacer tubes where the desiccant can take many weeks to absorb the moisture trapped in the airspace during manufacture.

A specially designed non-metallic tape is bonded to the sealant contact area on the Thermobar tube to provide a moisture and gas resistant barrier. This gives a massive advantage over systems using stainless steel or Aluminium foil.

The no-metal design, combined with a very low glass fibre content of the bar means that ‘A’ rated windows will be easily attained with the correct frame and glass combinations - anticipated values being below a psi value of 0.034 W/mK in a Plastic window frame.

All the fittings including a unique locking corner key which has no steel pins, will be manufactured here in the UK to keep costs to a minimum.

Add new comment