Date: 22 June 2022

The reason PRESS GLASS already for a long time has relied on glass inspection through online scanner systems:

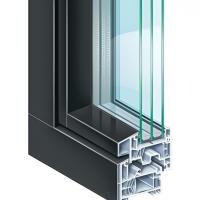

For over 30 years, PRESS GLASS has been manufacturing glass units for windows, doors, and facades of the highest quality and certification. Within a short period of time, the Polish company established itself as a leading manufacturer of insulating glass units. They succeeded in gaining a technological lead over their competitors by continuously improving product quality – using innovative components, production processes and service systems.

The globally active company, which now has 14 sites in Europe and North America, fully relies on automation. The production facilities used are completely linked, both mechanically and in terms of software.

For the new very demanding project of a fully automated insulating glass production for the commercial sector, PRESS GLASS focussed on Viprotron’s years of expertise. For the highest performing quality inspection, they count on Viprotron’s top line: the Quality Scanner 3D. This system is equipped with three independent inspection channels and since years it sets the benchmark when it comes to valid defect detection. Every single pane is inspected by a Quality Scanner 3D before it is finished: after automatic seaming and at every insulating glass line.

The Viprotron scanners are networked with the lines and deliver their results in real time to both line and higher-level production control software. Through the newly created management dashboard, both quality and production-relevant statistics are available online at any time.

Through this web-based application, all data can be accessed via smartphone, tablet, and PC. In addition, an integrated reporting system informs and alerts if the productivity targets are not reached or an accumulation of quality defects occurs.

“I currently consider Viprotron 3D scanners to be the best quality scanners on the market for the commercial sector” – Jakub Krakowski, Technology Development Manager at PRESS GLASS

Thanks to the good cooperation with the leading machine suppliers, Viprotron’s scanners are optimally designed for use in a networked world. Industry 4.0 is not a vision for Viprotron, but a reality.

We would like to thank PRESS GLASS for the implementation of this exciting and innovative project. And we are looking forward to being part of the further developments and quality assurance in the future.

You would like to optimize your plant as well?

We can help you here!

600450

600450

Add new comment