Date: 11 September 2015

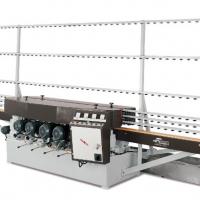

In detail:EDGING MACHINES TLS 15 AV C PC SP100: electronic straight-line edging machine with variable angle.The conveyor can handle weights up to 1.100 Kg (2.200 Kg on the whole machine). It can process thicknesses up to 100 mm, with sizes up to 12 x 3,21 mt. A light bridge crane with suction cups by Turomas-Tecnocat company will be joined to the edger for the handling of the glass sheets processed: live demonstrations will be performed every day! Other features on the displayed model are:

- OT 300 motorized washing machine fitted on the outlet conveyor to completely clean and dry the processed edge of the glass sheets. It automatically position itself according to the glass thickness set on the machine;

- independent motorization on the outlet conveyor;

- pneumatic tooth-type coupling (clutch) both on the inlet and the outlet conveyor as an help when loading and offloading glass;

- filters for the water tank to collect the remains of the laminates from the processed glass preventing clogging of the water lines;

- conveyor without bearings: this solution allows Lattuada machines to carry high weights and also to absorb even the smallest differences in thickness of the laminated glass;

- PC to manage all working phases;

- front controls for the rear arris on the diamond and polishing spindles: a device to help the operator make adjustments from the front versus behind the machine which saves precious time;

- ultrasonic sensor detects glass entering the machine: this guarantees toughness, long durability, precision and total insensitivity to water and dirt;

- oil equipment with end-line pressure switch: an additional safety to guarantee in every moment the perfect working of the fundamental lubrication system;

- cylinders with brakes for the automatic recovery of the polishing arris wheels wear.

.jpg)

- TLR 11 AV C: electronic straight-line edging machine with variable angle from 0 up to 45°, polished by liquid cerium oxide. This model is part of the TLR series, which is the most used by the major producers of stratified glass for the heavy building industry in Northern Europe. It is addressed to all glaziers with huge production of glasses with big sizes and great thicknesses.

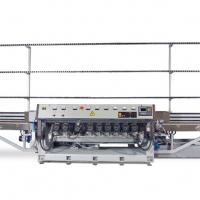

- TL 9 DD: electronic straight-line edging machine for the processing of flat edge with arris, polished by cerium oxide. Machine equipped with corner spindle and recommended for big productions of tempered glasses and/or high quality glasses for the interior design. It is able to process from glasses with important thicknesses to small glass stripes, up to a minimum size of height 60 mm.

.jpg)

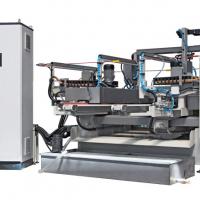

BEVELLING MACHINES

- GAMMA 723 PC: straight-line bevelling machine with 12 wheels for the processing of the bevel polished by liquid cerium oxide with PC to manage all working phases. Equipped also with OT 300 motorized washing machine fitted on the outlet conveyor. It can process also small glass pieces.

.jpg)

VERTICAL WASHING MACHINES

- OT 1600/500/4S: open top vertical washing and drying machine for glasses with a thickness from 3 up to 25 mm (on request up to 40 mm) and with minimum dimensions of 350 mm. Equipped on the outlet side with a black panel with inspection lights to help the check of the glass cleanliness degree. The regulation both of the speed and of the glass thickness are motorized, in order to guarantee a high washing quality on every thickness. All our washing machines can be integrated with vertical CNC machines as well as included in our edging and bevelling lines, also thanks to the possibility to have the work surface at the same height. On request it is possible to manage thickness and speed adjustment ‘in-line’.

.jpg)

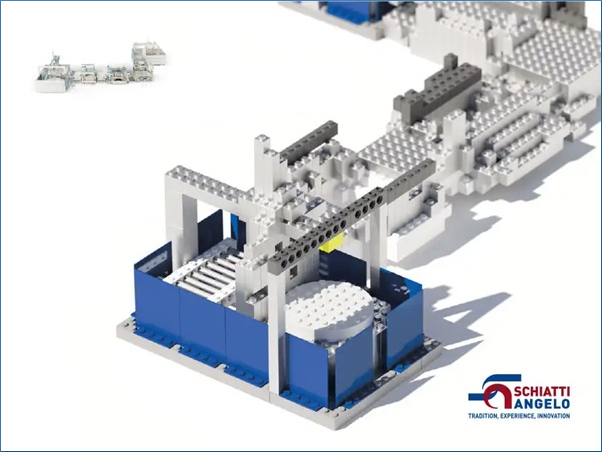

Our machines can be integrated with:

- robots installed between two or more grinders (most common application is with two machines and one robot).

- ‘loop’ systems that can be installed on a single machine, to automate and speed up the work cycle, thus obtaining increased optimization of productivity: the easiest, most flexible and simple solution. The system can load the glasses, bring them from the outlet conveyor to the inlet conveyor rotating them 90°. Also available with automatic load/unload from harp racks management.

- piece rotating devices for complete grinding lines.

- complete vertical lines of harp racks, edging, washing, drilling and milling machines.

.jpg)

Hall 22 - Booth E-01 / G-02

Add new comment