Via A. Locatelli 123,

Zogno 24019 BG

Italy

CMS Spa

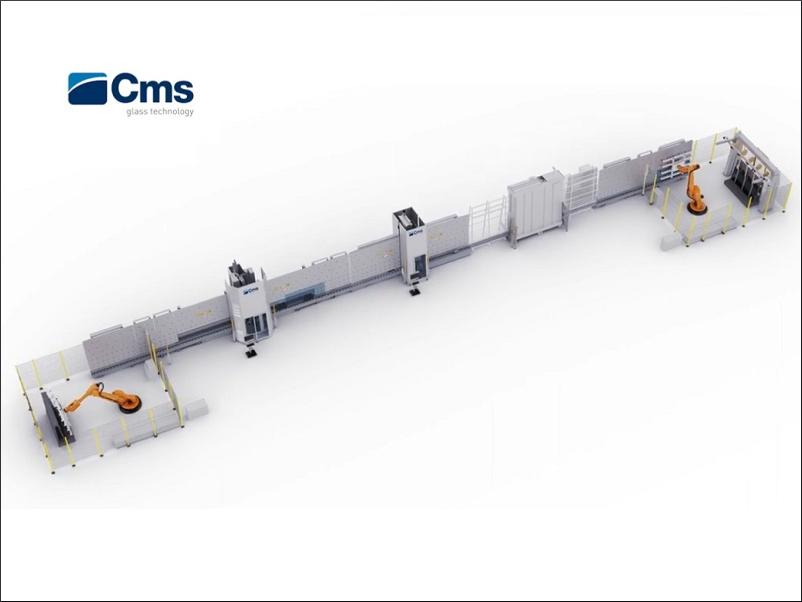

CMS Glass Technology is an industry leader in the field of curved and flat glass working, with technologically advanced solutions such as numerically controlled machining centers, cutting benches, and water-jet cutting systems.

CMS has been part of the SCM Group, a world leader in technologies for processing a wide range of materials, since 2002: wood, plastic, glass, stone, metal and composite materials. The companies of the Group are the reliable partners of established industries operating worldwide in various trade sectors: from furniture to building, from automotive to aerospace, from boating to plastic materials. SCM Group coordinates, supports and develops a system of industrial outstanding realities, organized into 3 large highly-specialized production sites in Italy, with over 4,000 employees and a direct presence in the 5 continents.

Supplier of Cutting and Grinding Technology, Breaking, Storage and Handling Systems, X/Y/C Cutting Machines, and full automatic cutting line --CNC Machines, Drilling CNC--Edgin line--Handling equipment.

Products

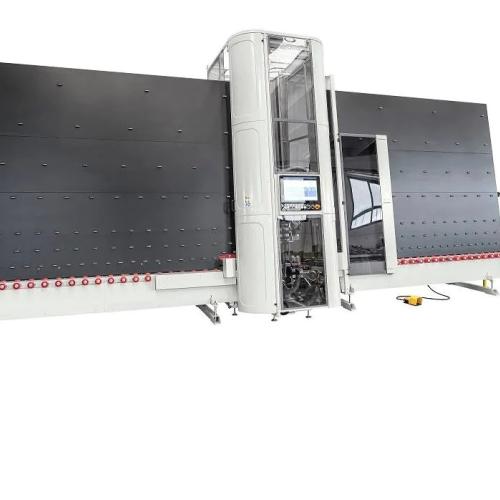

Cms aura is the vertical dry seaming machine specially developed to machine edges without the use of water (dry seaming). Aura can be used as a stand-alone machine, in line with a vertical washing machine and is the perfect machine to be part of a double glazing line.

Aura can seam monolithic, laminated or low-e treated glass.

Aura is designed to meet the needs of customers who demand ease of use, quick installation, reliability and low cost of system ownership.

Worry free!

The operator loads the glass and starts the processing cycle, the machine automatically measures the incoming glass (height, length and thickness) and machines the edge.

Aura also adapts its operating units to different thicknesses.

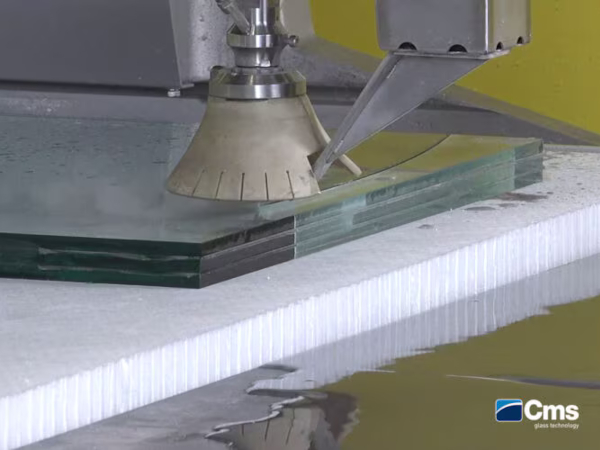

CMS electa is the new 3- or 4-axis (optional) CNC machining center for processing flat glass, whether thick, thin, laminated or bulletproof.

CMS electa features the smallest footprint and the largest work area in its category, and can perform many types of machining: the 3-axis version performs grinding, edge polishing, drilling and milling, while the 4-axis version can also perform cup wheel polishing, diamond disc cutting, engraving and 5° chamfering.

The high inertia and thickness of the exclusive Metal Synthetic Technology (MST) worktable, which replaces the conventional aluminum worktable, dampens vibrations and helps to improve the quality of the machined glass.

With a maximum axis speed of 72 m/min, CMS electa guarantees top performance and is the perfect machine to increase productivity since it performs high-speed grinding and can machine multiple workpieces on the same worktable.

5-axis interpolated Numerically Controlled machining center with automatic tool change for the working of flat glass sheets of all thicknesses and bent glass. It carries out all types of edge grinding and polishing, arising, milling, cutting with disk, drilling, contouring, engraving, writing, variable-angle beveling operations and special machining. It’s the sturdiest machining center in the field, which makes it ideal for any type of working condition.

- wide rotation of axes C (4th axis) and B (5th axis) for the realization of 0-90° variable-angle beveling and dynamic variation of the bevel depth. The configuration with diamond disk is also available for straight and inclined cuts

- Z-axis stroke from 460 to 900 mm for the most demanding works on bullet-proof, military, aerospace and special glass sheets

- thanks to the high configurability of the machine, it is possible to process glass sheets in massive sizes

Ypsos is the newest vertical machining center developed by CMS, ideal to process float and laminated glass sheets, entirely designed thanks to many decades of experience in the glass industry. This is the first and only vertical CNC machining center capable of grinding and polishing with two heads at the same time. This project was conceived to reach the best reliability ever in the vertical CNC category. The new software has been designed to make the user interface more efficient and intuitive than ever. Based on the configuration selected. Ypsos can carry out seaming, polished and industrial grinding, milling and coaxial drilling operations.

This machine provides absolute accuracy and quality, accompanied by the classic benefits in terms of productivity and versatility given by the vertical machining process. Available in 3 standard sizes, it allows the processing of small and large-sized parts up to 6,000 x 3,300mm max. (additional maximum processable sizes available upon request).Ypsos can be used as a stand-alone machine, in line with a drilling-milling machine or inside an insulating line.

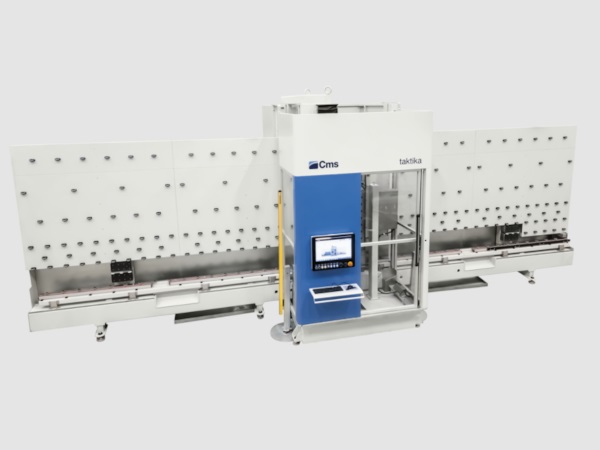

Taktika is the compact vertical machining center developed by CMS for the greatest flexibility in small spaces. The project was conceived for small and medium-sized glass factories that need to increase their efficiency, and is also ideal for larger companies that need the flexibility to manage small batches of glass.

The new Cms Active software was designed to make the user interface more efficient and user-friendly than ever.

Taktika can perform seaming, industrial and smooth grinding, milling and coaxial drilling; it can be used stand-alone or in line with a vertical washing machine to wash the glass immediately after processing.

CNC vertical machine for drilling, countersinking, milling and notching operations on monolithic, laminated and Low-E glass.

- possibility to work both rectangular and shaped glass sheets (one rectilinear side required)

- two coaxial opposed electrospindles and tool cooling system with internal and external water, which enables a higher finishing and machining quality

- two 9+9 stations NC-controlled rotating tool crib installed on a carriage fixed to the electrospindle, ensure tool change operations in the shortest time

- high-pressure water cushion (patented)

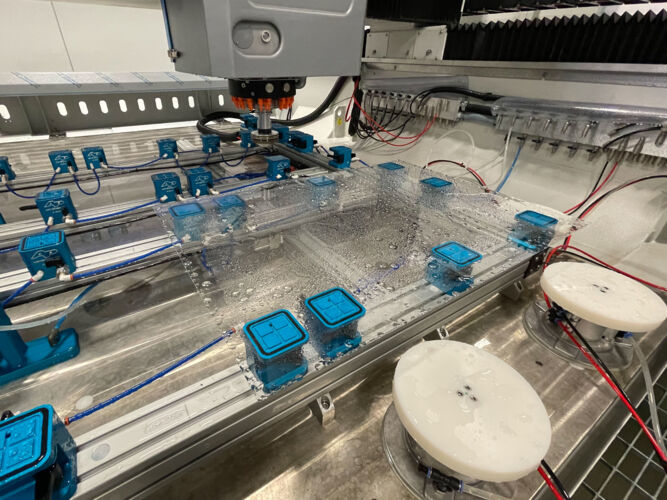

The ultimate machine tool specifically conceived and designed with advanced technical solutions for the waterjet cutting technology, in order to achieve unmatched performance. Proline is built around a stainless-steel frame ready for integration with the “Dredge”, a fully automated and maintenance free abrasive removal system, an automatic water level control for submerged cutting and rotary option for pipes processing. This innovative, easy configurable concept has not only the abrasive tank installed on-board, but also the electric servodriven high-pressure pump is integrated with the machine frame, a big saving in terms of overall layout. The overall machine structure, especially the rugged gantry system, offers unmatched rigidity and thus consistent cutting accuracy over time, thanks also to the ground helical rack and pinions, combined with high precision gearboxes.

The linear guides are protected by the innovative “Powder free” system composed of overlapping way covers, which ensures the highest protection against moisture, dirt and dust.

- more versatility: new models and extensive supply of accessories and standard arrangements for faster, less costly retrofits

- more reliable: NC and digital drivers for full control of the cutting parameters

- more compact: accessories integrated into the base structure for easy, fast installation and re-commissioning

Agil tr is the most compact and versatile cutting table ever made by CMS.

It is a table that can automatically cut monolithic (float) glass sheets and semi-automatically cut laminated glass sheets thanks to the double-zero system.

- The table is equipped with 4 arms for loading/unloading the sheets and a c-axis to perform both straight and shaped cuts.

- Easy to install and compact in size, it can cut large sheets up to 3810 mm x 2600 mm.

- The table can be equipped with an automatic tool change and a low-e coating removal grinding wheel, and a vinyl removal system.