Others also read

| In the latest Glastory blog post, Per Jensen analyzes the holistic approach to grinding.

Author: Per Jensen | Glaston

Source: glastory.net

Author: Per Jensen | Glaston

Source: glastory.net

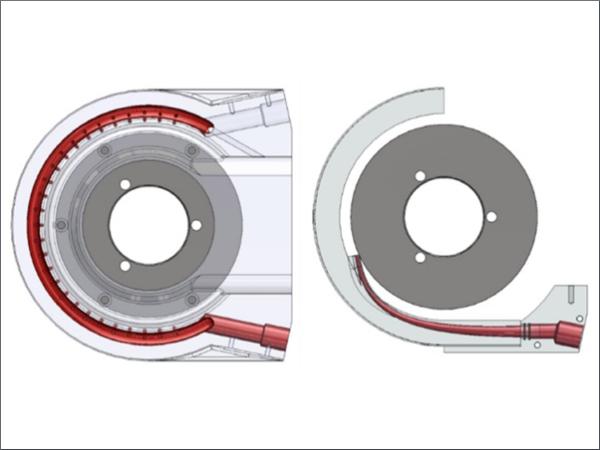

| Different cooling systems are tested against a standard coolant system in a series of experiments. Their performance in terms of edge surface roughness and grinding wheel wear is being compared.

| What are the real benefits that robotics, the IOT (Internet of Things) and the Automatic machines can bring to glass grinding?

| Identification and optimisation of cutting process parameters

| The article presents some basics about the processing steps of glass edges surfaces, introduces the considered grinding and polishing cup wheels and gives an overview of the performed experimental examinations.

| After seaming, grinding glass edges is another important work step in glass edge processing. The process is primarily used to remove overbreaks and underbreaks at the edges and to process the glass sheets to size.

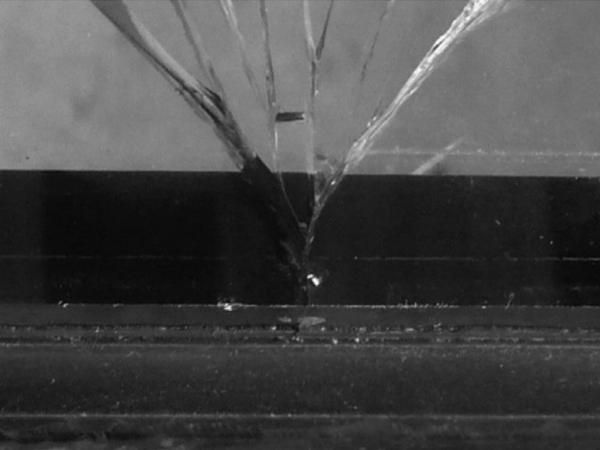

| In glass edge processing, cutting the glass sheet is directly followed by the seaming process. Fully unprocessed glass edges exhibit overbreaks and underbreaks, conchoidal fractures, as well as micro-cracks along the broken edge.

| In glass edge processing, the requirements for the finished components can vary greatly depending on the location and purpose.

| The new LiSEC glass edge deletion machines are equipped with improved sensor technology. This measures with greater precision and therefore guarantees constantly high finishing quality of the glass edges.

| This article will focus on the edge stability of PVB and ionoplast laminates and address the potential causes of blemishes.