This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Author: Vaughn Schauss - Kuraray America, Inc

Abstract

Glass is an essential component for any type of building. Its transparency enhances daylighting and provides occupants a view to the outside. Whether in retail, office, government, educational, religious, or residential structures, glass is an integral part of the design. As a building material, however, its brittleness can be a deterrence from a security perspective. Laminating glass together with a PVB or ionoplast interlayer can help mitigate security threats that range from smash and grab burglary, forced entry, ballistics, to even bomb blast. With these many different types of security threats, questions have arisen over what level of security is needed, which test standard is applicable, and what type of laminate is required. A test program focused on burglary and forced entry was conducted to investigate the performance of laminated glass made with PVB and ionoplast interlayer. Standards from ASTM, Underwriters’ Laboratories, and the European Committee for Standardization (CEN) were chosen as the basis for testing. The results were then compared and grouped based on common laminate makeups.

1 Introduction

Architects and designers are incorporating more glass in buildings for better aesthetics, improved daylighting, and occupancy comfort. Despite these benefits, glass is also the most vulnerable component of the building envelope when it comes to attacks by intruders. The use of laminated glass with PVB and ionoplast interlayers not only offers improved safety but can also be designed to help mitigate security threats ranging from basic safety to burglary and forced entry resistance and even ballistic protection. With a wide range of potential threats, it can be overwhelming to determine what type of laminate is required.

To address this issue, a test program was initiated to determine how different laminate constructions perform when subjected to various security glazing test methods. The laminates were then grouped based on how they performed.

2 Security Levels When specifying glazing for a new building or retrofitting an old building, assessing the level of security needed is a critical step that should not be overlooked. While it may not be possible to completely prevent intrusion, the objective should be to provide sufficient delay to be able to detect and respond to the intruder. Laminated glass can be designed to deter intruders by making it difficult to gain entry and thereby increasing the time required to enter the building. Although this sounds simple, there are multiple types of threats like the opportunistic smash and grab burglary to organized multiple persons forced entry. In addition, since each project may have multiple needs depending on the location of the glazing, this can become overwhelming. To help alleviate some of the confusion, the National Glass Association (NGA) recently published a Glass Technical Paper on the topic of school safety. The document FB71-21 School Security Glazing organized the various security threats into seven categories and listed standardized test methods that correspond to each category [1]. The seven security categories are:

- Basic Safety Glazing

- Enhanced

- Forced Entry

- Enhanced Forced Entry

- Ballistic Protection

- Multiple Forced Entry Assault

- Blast Resistance

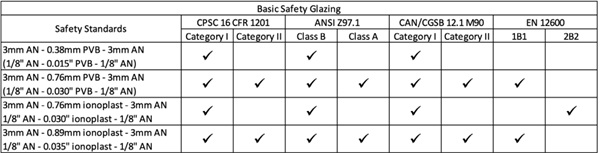

Basic Safety Glazing

Laminated safety glazing is focused primarily on reducing injuries during accidental human impact. It is required by many building codes for use in hazardous locations like doors, and showers. While it is not typically thought of as security glazing, since it does retain the glass fragments after breakage, it provides a basic level of security by delaying immediate access. Testing for safety glazing attempts to recreate the accidental human impact by using a pendulum with a soft body impactor. ANSI Z97.1 and EN 12600 are two common test methods for this safety glazing. [2, 3]

The ANSI Z97.1 pendulum test uses a leather punching bag as the impactor. It is filled with lead shot to a weight of 45.4 kg (100 lb.) and then wrapped in tape to reduce damage to the bag. There are two classes of safety glass determined by the drop height. Class A rating has a drop height between 1219 and 1232 mm (48 to 48.5 in) whereas Class B has a drop height between 457 and 470mm (18 to 18.5 in). The pendulum test according to EN 12600 uses a 50 kg (110 lb.) double tyre, also called twin tyre. The EN method has three classifications based on drop heights, Class 3 has a drop height of 190 mm (7.5 in.), Class 2 is 450 mm (17.7 in.), and Class 1 is 1200mm (47.2 in.) Both test methods require no opening through which a 76 mm (3 in.) sphere can pass. In addition, both methods also require that if any particles detach within three minutes post impact, the particles in total shall not weigh more than 10,000 mm2 (15.5 in2) of the original test sample.

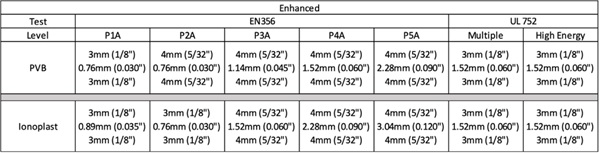

Enhanced

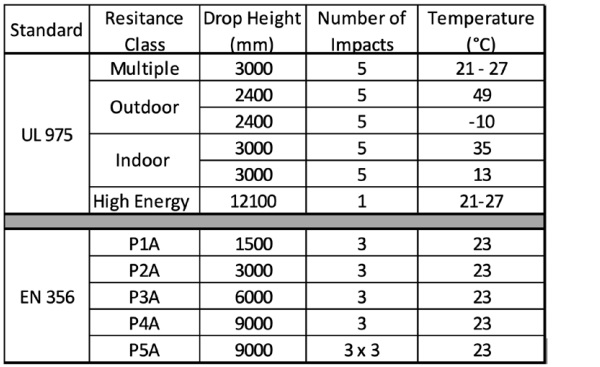

This security category addresses smash and grab burglary. This type of security threat often involves the use of hands or simple tools like hammers to quickly break the glass to steal valuables or enter a building. An example of this type of security threat is a jewelry store display case where thieves will quickly smash the glass, grab the jewelry, and run. The use of laminated glass in this application will slow the thieves down, requiring multiple impacts, and losing valuable get away time. Testing for this security level typically involves impacting the glass with a metal ball from varying heights. UL Solutions UL 972 Burglary Resisting Glazing and EN 356 Axe Test – Resistance Against Manual Attack are two examples. [4,5] UL 972 subjects the glazing sample to multiple impacts of an 82 mm (3.25 in) diameter steel ball weighing 2.26 kg (5 lb.). The method describes four different categories: multiple impact, outdoor use, indoor use, and high energy. These categories differ by the drop height as well as the test temperature. EN 356 uses a larger 100 mm diameter steel ball weighing 411 kg (9 lb.). This standard has five classes based on different drop heights. Refer to figure 1 for details on the drop heights. In both test methods, the samples pass if none of the balls penetrates the glass.

Forced Entry

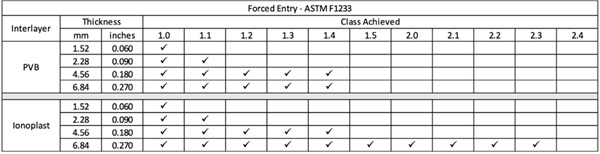

The previous categories dealt with accidental and opportunistic threats, whereas the forced entry category is focused on determined intruders inflicting repeated assaults with a variety of tools. With multiple classification levels, each offering an increasing amount of time to gain entry, this category of security glazing may be used in non-monitored areas or areas of high risk such as high-end retail store fronts. Test methods for this category rely on a variety of tools and time or number of impacts to forcibly penetrate the sample. The tools can be sharp, blunt, or cause thermal or chemical deterioration. EN 356 as well as ASTM F1233 Standard Test Method for Security Glazing Materials and Systems are both suitable for this category. [5,6]

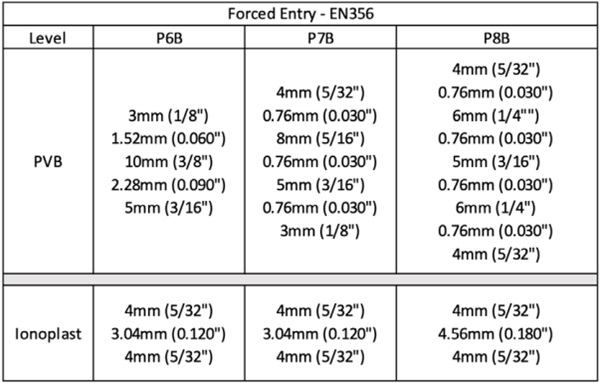

EN 356, referenced previously as a ball drop test, has three higher level categories that use an axe blade to cut through the glass. In this part of the test, the glass is repeatedly struck with a hammer to break the glass by applying a minimum of twelve strikes. The hammer’s impact location is rotated so that a square is formed. After all the glass is broken, the hammer is replaced with an axe head. The sample is then struck with the axe head in the same spot until it penetrates the sample. The position of the axe head is moved to the next location and the process is repeated until the entire square has been cut out. The total number of strikes is tallied (hammer and axe) and a category of resistance is assigned. If the total number of strikes is between 30 and 50, then a P6B rating is assigned.

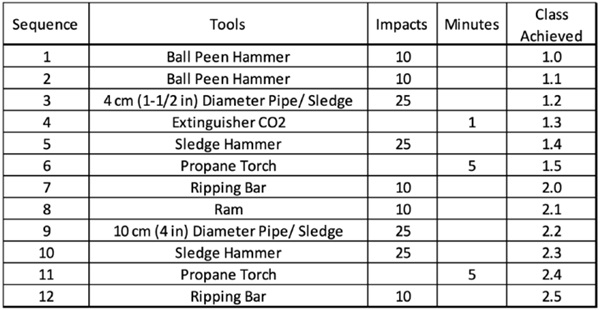

P7B is for 51 to 70 strikes, and any sample with more than 70 strikes is rated as P8B. ASTM F1233 is a comprehensive test method for security glazing consisting of 41 classification levels utilizing blunt and sharp tool impacts, thermal stress, and chemical deterioration. The test method also includes a ballistics section which will be discussed later. For this paper, only the first 12 levels will be presented. Unlike the previous test methods discussed, this standard does not use a machine for the testing. Instead, it employs six muscular males weighing between 82 and 113 kg (180 – 250 lb.) to enthusiastically assault the glass. The test personnel use the tools listed in figure 2 to attack the glass until an opening forms. There are two methods for checking if the glass fails. The first is the passage of contraband. If an opening is large enough to allow the passage of a 3 mm (1/8 in) diameter shape, then it will be considered a failure for contraband. The next criterion for failure is the body passage.

Any opening large enough to allow the passage of a 20 by 20 by 13 cm (8 by 8 by 5 in.) rectangular object fails the body passage.

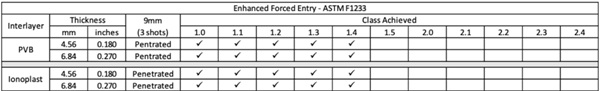

Enhanced Forced Entry

This category is very similar to the previous category except the glass is pre-weakened with ballistic impacts. Enhanced forced entry security glazing is not intended to be used for ballistic rated glass as the projectiles are allowed to penetrate the samples. The addition of this initial step is intended to mimic an active shooter situation where the gunman shoots through the glass to weaken it prior to using tools to forcibly enter. ASTM F1233 allows samples being tested for forced entry to be subjected to ballistic assault prior to beginning the forced entry testing. Even if perforation occurs, the observation is noted, and the testing is allowed to continue. [6]

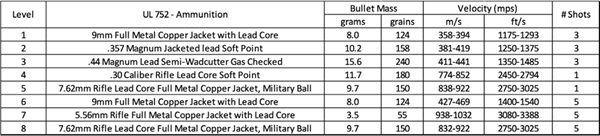

Ballistic Protection

Products in this category are designed to resist ballistic assault without penetration, and are typically installed in banks, courthouses, police stations, and other high security government and commercial buildings. There are multiple standards that specify the performance requirements such as ASTM F1233, UL Solutions UL 752, National Institute of Justice (NIJ) Standard 0108.1, and the European standard EN 1063. The standards classify the products based on various handguns, rifles, and shotguns as seen in figure 3. [6,7,8,9]

Multiple Forced Entry Assault

This category combines bullet resistance and forced entry. The samples are first subjected to the ballistic assault, but unlike the enhanced forced entry, no bullets are allowed to penetrate the sample. After the ballistic portion, the samples are tested for forced entry. The forced entry portion of the testing may be performed based on a specific tool sequence or for a specified time. Products in this category would typically be used in high security buildings like government embassies. ASTM F1233 is one standard that can be used for this testing, but there are also other government standards like the United States Department of State standard SD-STD-01.01. [6,10]

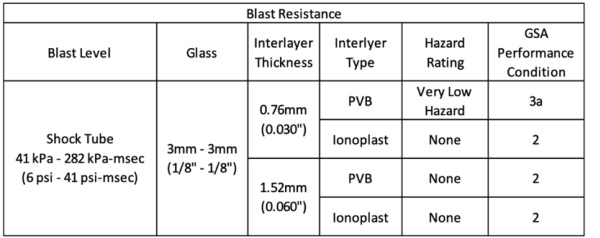

Blast Resistance

Blast resistant glazing can be used to reduce the hazards associated with an explosion, primarily flying glass and direct exposure to the shock waves. Testing can be done in a laboratory setting using shock tube or arena testing with live explosives. ASTM F1642 provides instructions for performing the test while the specifications and blast levels are discussed in ASTM F2912. [11,12] After exposure to the blast, the glazing is rated based on the hazard it poses to occupants.

The hazard rating considers glass breakage and how far the glass fragments fly into the room.

3 Test Results

To investigate the performance of laminated glass with PVB and ionoplast interlayers, multiple test programs were initiated. The following test data is presented primarily as a guide and should not be considered certified security products. The testing was conducted on glass only samples whereas certification may require the full frame and glazing assembly to be tested. Test data for ballistic and multiple forced entry assault was intentionally not included. These security levels involve multi-layer laminates, and the configurations are often proprietary.

4 Conclusion

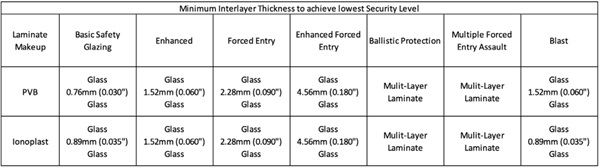

The intent of the various test programs was to better understand the role of the interlayer when designing security glazing. Evaluation of the test data implies that as the interlayer thickness increases, the level of security also increases. The same relationship is true for multi-layer laminates. Based on this evidence, figure 10 provides a summary of the minimum interlayer thickness needed to meet the lowest level for each security category.

As an essential building component to increase daylighting and occupancy comfort, the brittleness of glass can be a deterrence from a security perspective. Specifying laminated glass with PVB and ionoplast interlayers helps overcome the security concerns of glass.

Whether the building owner needs basic safety glazing or something a little more secure like forced entry, laminated glass can be designed to meet the security requirements.

References

- National Glass Association. (2021). School Security Glazing (Glass Technical Paper FB71-21). Available at: www.glass.org

- From ANSI Z97.1-2015, “For Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test”, copyright Accredited Standards Committee (ASC) Z97; 800 SW Jackson St Suite 1500, Topeka, KS 66612 – 1200. A copy of the complete standard may be obtained from www.ansiz97.com.

- DIN (2013) Glass in Building – Pendulum Tests – Impact Test Method and Classification for Flat Glass (EN 12600). Available at: https://www.en-standard. eu/store/

- UL Solutions (2006). Burglary Resisting Glazing Material (UL 972). Available at: https:// standardscatalog.ul.com/Catalog.aspx

- DIN (2000) Glass in Building – Security Glazing –Testing and Classification of Resistance Against Manual Attack (EN 356). Available at: https://www. en-standard.eu/store/

- ASTM F1233-21, Standard Test Method for Security Glazing Materials And Systems, ASTM International, West Conshohocken, PA, 2021, www. astm.org

- UL Solutions (2005). Standard for BulletResisting Equipment (UL 752). Available at: https:// standardscatalog.ul.com/Catalog.aspx

- NIJ. (1985). Ballistic Resistance Protective Materials (NIJ Standard 0108.01). Available at: https://nij.ojp.gov/library/publications/ballisticresistant-protective-materials-nij-standard-010801

- DIN (2000) Glass in Building – Security Glazing –Testing and Classification of Resistance Against Bullet Attack (EN 1063). Available at: https://www. en-standard.eu/store/

- U.S. Department of State. (1993). Certification Standard – Forced Entry and Ballistic Resistance of Structural Systems (SD-STD-01.01, Revision G).

- ASTM F1642-12, Standard Test Method for Glazing and Glazing Systems Subject to Airblast Loadings, ASTM International, West Conshohocken, PA, 2012, www.astm.org

- ASTM F2912-11, Standard Specification for Glazing and Glazing Systems Subject to Airblast Loadings, ASTM International, West Conshohocken, PA, 2011, www.astm.org