Architectural Glass Laminating Guide - Part 7

By Luc Moeyersons

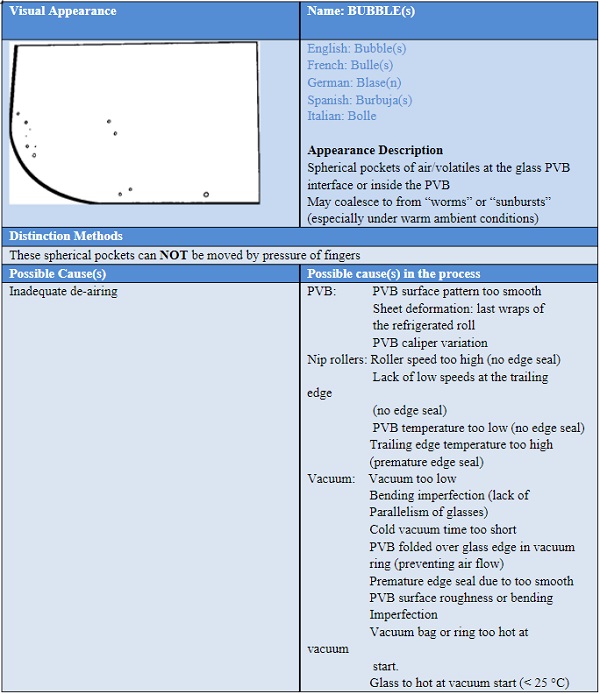

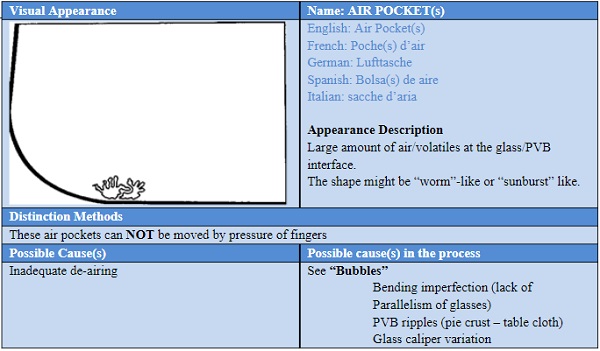

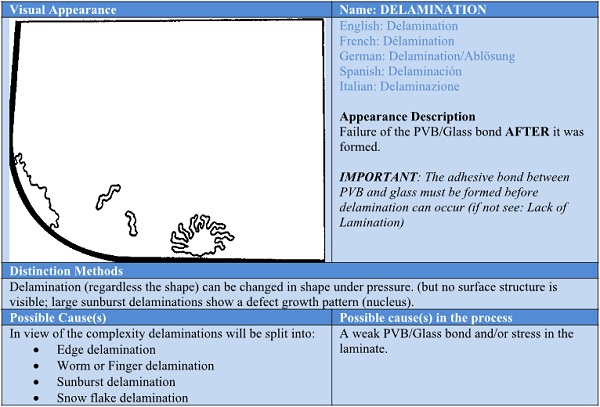

Bubble/delamination formation

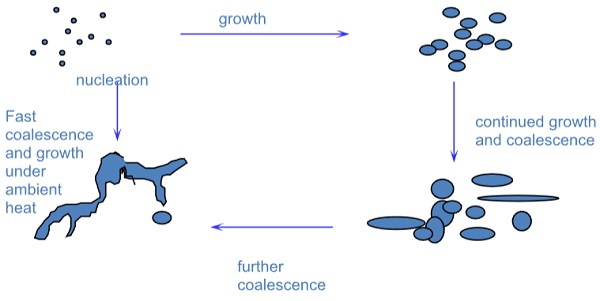

Some air will be dissolved in the PVB layer.

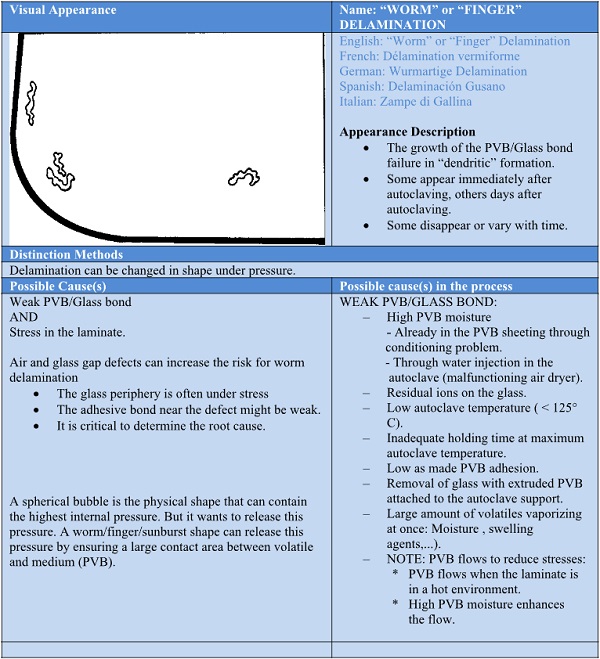

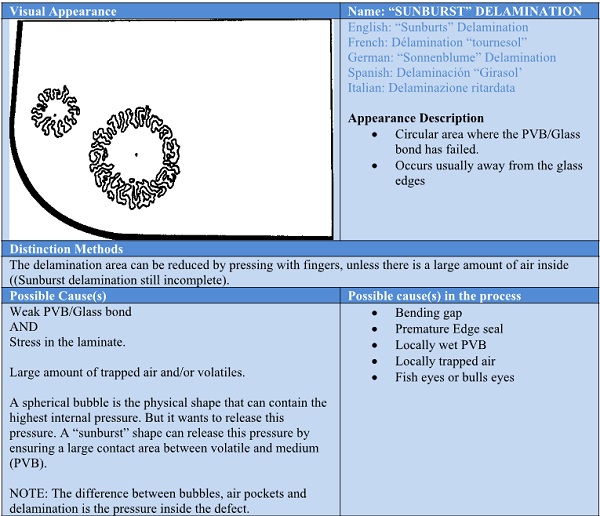

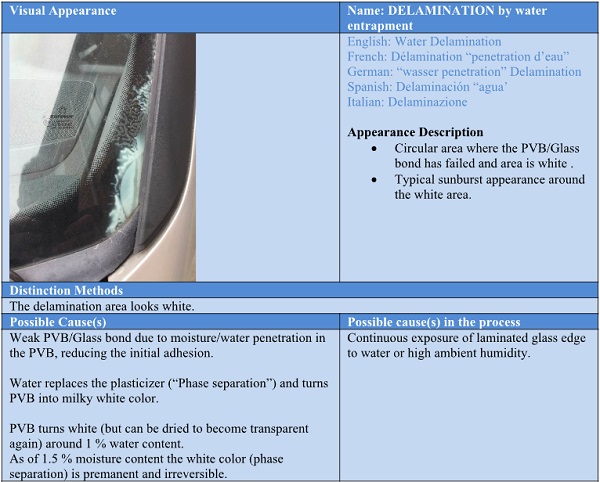

When large in amount or when laminated glass (PVB) is under warm conditions (softening of PVB) these “micro bubbles” will grow and coalesce into “worm” or “finger”-like delamination and ultimately into “sunburst” delamination.

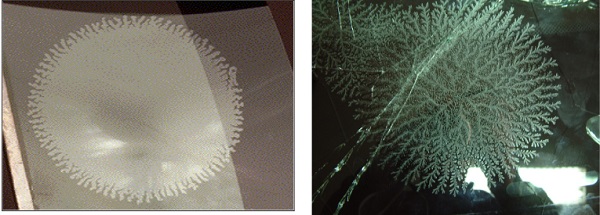

A spherical shape bubble can “support’ a high internal pressure (needed to form and come out of solution), but wants to relief that pressure. Due to the sunburst shape (very large contact area between volatile and PVB) this pressure is released significantly. Ambient temperature (softness of PVB) will influence the speed of this phenomenon. Often small glass chips are found to be a nucleus for the air bubble to grow around.

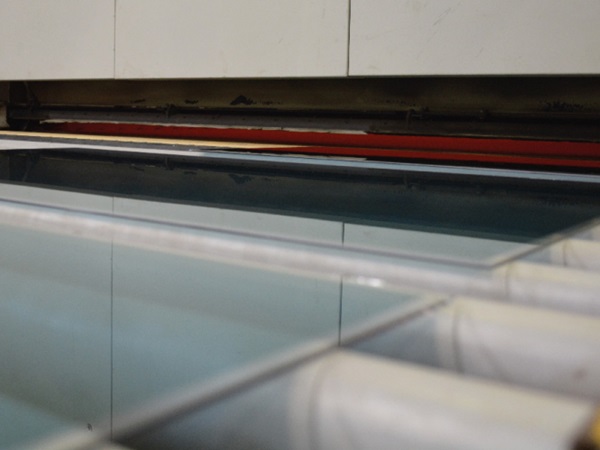

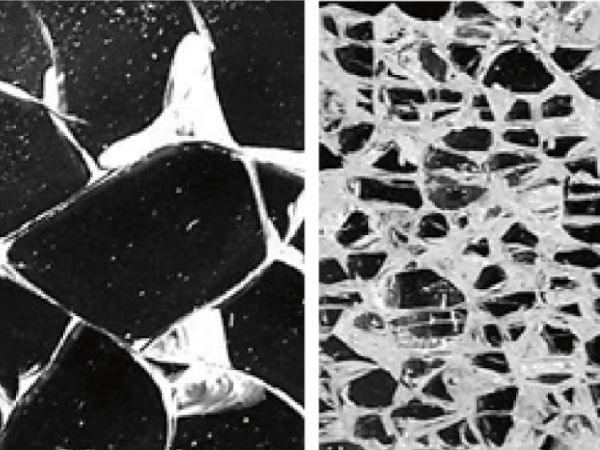

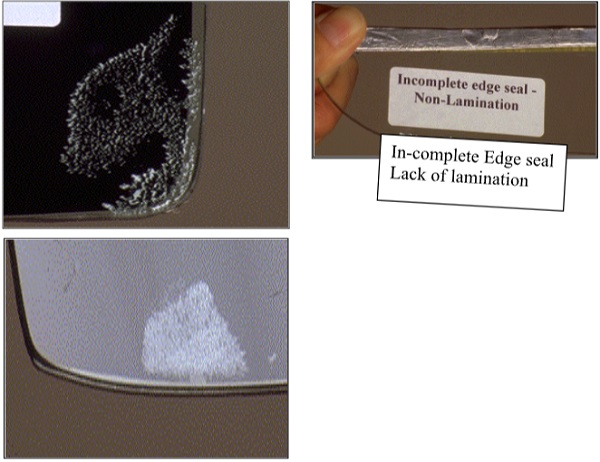

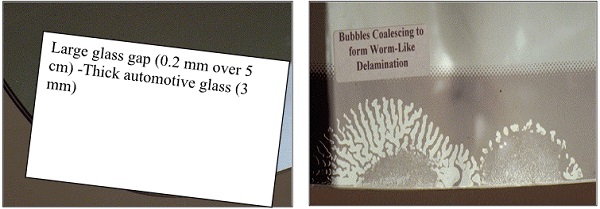

The difference in shape is due to the location of the delamination.

Left picture delamination is in between PVB and glass; the right picture delamination is in between regular and acoustic (softer) PVB layer (tri-layer acoustic PVB has a soft PVB core layer and 2 regular PVB layers at each side).

Compatibility problems between silicones/sealants and PVB are not reviewed in this document.

Nor are the excessive use of primers/cleaning products when gluing glass on an aluminium frame (Structural Sealant glazing) or bad installation (none or inadequate draining).