Throughout this series, we will delve into the cutting-edge advancements and innovations in insulating glass (IG) production. This first episode is dedicated to the TPS® technology. Join us as we uncover the history of TPS®, what sets this technology apart and what new developments are available today for IG producers.

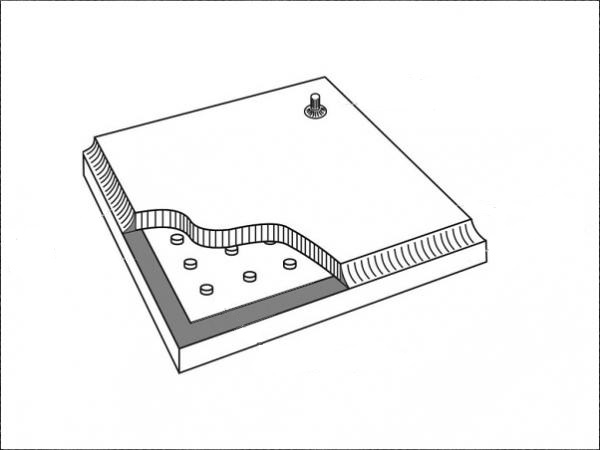

TPS® stands for Thermo Plastic Spacer, belonging to the “warm edge” spacer category. However, TPS® represents much more than a mere acronym. It encompasses precise and robust technology for producing double to quadruple IG units.

History of TPS

The origins of TPS® trace back to 1994 when the company’s visionary founder, Karl Lenhardt, recognized the pressing need to automate insulating glass production. Soon after, an applicator was developed that applied the spacer directly onto the glass – first horizontally and then vertically, as is done to this day. This process revolutionized insulating glass production by eliminating manual spacer application.

Presently, more than 160 TPS® IG production lines are operational worldwide. This translated into over 100 million TPS® IG units produced on these lines to date.

Advantages of the TPS technology

The TPS® technology offers numerous advantages. Most notably, all IG units can be produced on a single production line – regardless of their format. This eliminates the need for separate production steps such as sawing, bending, connecting, desiccant filling and butyl-coating. And thanks to the high level of automation, the process requires only two operators.

To support sustainability, TPS® ensures the right spacer in exactly the right quantity, with no waste or offcuts.

Last but not least, TPS® makes uninterrupted operation possible due to the special dual-drum pump system, which allows drum changes without stopping the operation. Furthermore, the newly developed and Glaston-patented follower plate optimizes the material flow, resulting in up to 35% improved material output.

All these benefits significantly save time and money for IG producers.

For more specific details on the TPS® production process, we invite you to watch the video above.

More about the TPS® technology visit the technology page.

Comments

Wow. This looks promising.

This amazing process has transformed insulating glass production by taking care of the tedious manual spacer application. And guess what? With over 160 TPS® IG production lines operating worldwide, this technology is making lives easier for people worldwide. Congrats on being part of such an innovative industry!