Others also read

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

Sparklike, a global leader in non-destructive gas measurement solutions for insulating glass units (IGUs), announced the appointment of Sasu Koivumäki to its Board of Directors.

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

This year marks the 10th anniversary of Sparklike Laser Portable™, a major milestone in the development of non-destructive gas measurement for insulating glass units.

A smart solution for lighter, slimmer, and more efficient insulated glass units.

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

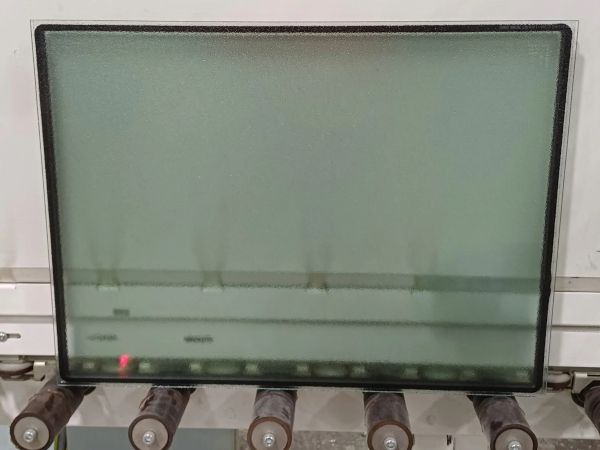

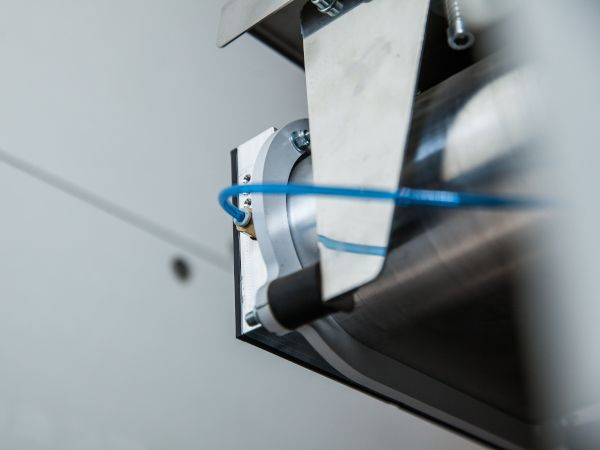

Sparklike Laser Integrated™ is a fully automated, non-destructive gas measurement system designed to be integrated directly into insulating glass (IG) production lines.

Sparklike continues to strengthen its global presence, connecting with industry professionals and showcasing its innovative gas measurement solutions for insulating glass (IGU) quality assurance.

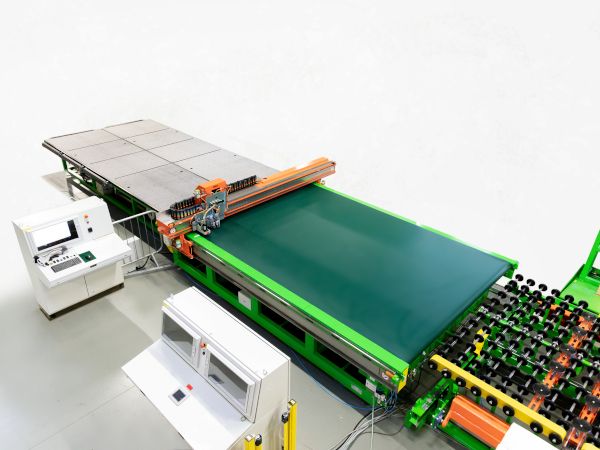

Forel introduces a new manufacturing solution for Triple Thin IGUs with Flexible Spacer, combining advanced automation, precision, and efficiency for next-generation insulating glass production.

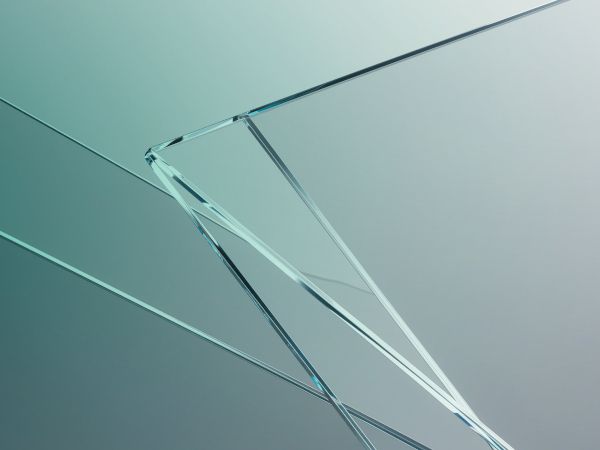

In construction, automotive and interior design, there are multiple applications and often they require solutions that are both lightweight and durable, with flawless finishing.

HEGLA will showcase its latest Thin Glass Cutting System, Galactic-TG, at Booth #16048 during GlassBuild America.

GlassKote FGI secures AUD 1.2B to build two next-generation low-iron float glass plants, setting new global standards for innovation and sustainability.

The quality and durability of insulating glass units (IGUs) rely on precise manufacturing processes, especially when it comes to gas fill levels and leakage rates.

Now online: the new video dedicated to the manufacturing of triple glazed units with thin inner glass using the Forel High Tech line with TA thermoplastic spacer applicator.

Sparklike technology helps IGUs stay durable and energy-efficient by preventing gas leakage.

This autumn, Sparklike has been actively present at major international trade shows, reinforcing its commitment to innovation and global collaboration in the glass industry.

Sparklike now offers a free online IG Configurator, helping manufacturers quickly check if their insulating glass units are compatible with Sparklike Laser for accurate, non-invasive gas measurement.

Glaston will showcase smart, energy-efficient glass processing solutions at VITRUM 2025.

Accurately measuring argon in insulating glass units (IGUs) is essential to ensure energy efficiency and sustainability—here’s how advanced testing methods, including Sparklike solutions, make it possible.

HORN is proud to announce that the HORN HRD-BEAM contactless glass level measurement system has already been installed 20 times on glass furnaces worldwide.

HEGLA showcases smart glass solutions at Vitrum 2025 in Milan.

Since 1993, Huadong Coating has delivered top insulating glass solutions—now enhanced with Sparklike technology for precise gas measurement.

Learn how to get the most accurate results with Sparklike Laser devices for non-invasive IGU gas concentration measurement.

The cutting of thin glass is extremely demanding! That’s why HEGLA has designed a Galactic float glass cutting system specially for the needs of thin glass.

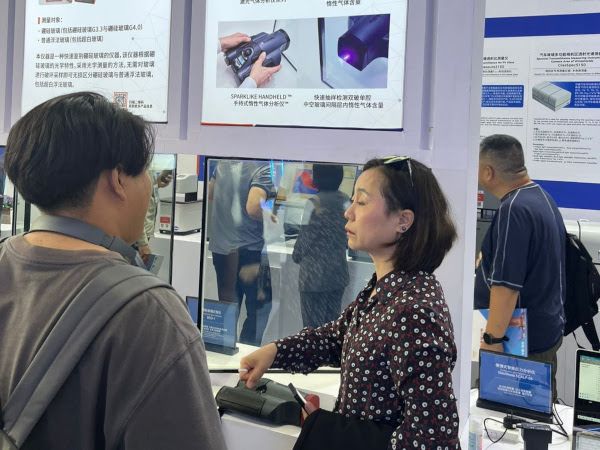

Sparklike launched the 2025 trade fair season with key appearances at China Glass 2025 in Beijing and Glass Performance Days in Tampere.