Others also read

Yorglass Satin Range combines aesthetics with high quality

POLFLAM® BR fire-resistant bent glass, as well as our fire-resistant flat glass, were both used in the glazing for the BONARKA underground car park’s stunning entryway.

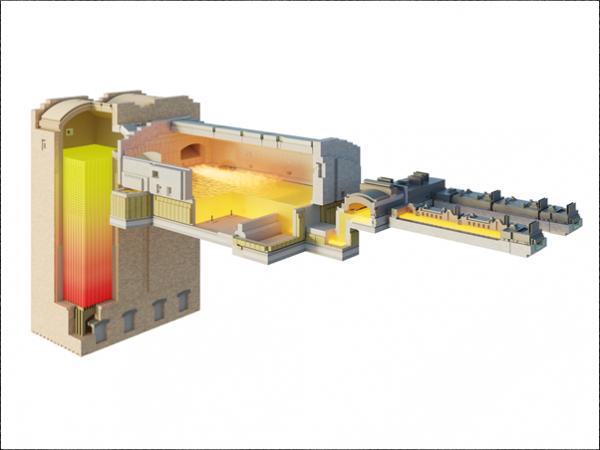

HORN® has started the furnace heat-up process at GCA's new 400 t/d end fired furnace in Turkey.

Developed by Şişecam Group, revolutionary V-Block Technology which prevents the growth of microorganisms on glass surfaces, is ready to go in to markets as the world’s first antimicrobial glassware.

Inside and out, interlayers from Trosifol prove their capabilities in structural and aesthetic applications... both sides of the Atlantic.

In 2020, the record number of 135 parcels from 2019 was exceeded by far. No less than 222 parcels were donated.

Şişecam begins producing the world's first antimicrobial glassware products that are also effective against coronavirus

Employees, customers and the company itself benefit from continuity in the company's workforce. This is especially true for the traditional company HORN® in Plößberg.

The existing furnace will be enlarged by HORN® and equipped with new heating equipment and safety control.

The entire construction and commissioning was supervised and managed by HORN®.

The glass panes are joined with fireproof silicone sealants and the resulting joints are only 2 mm wide. The pane edges are aesthetically finished with a strip of ceramic paint of appropriate width in any RAL colour.

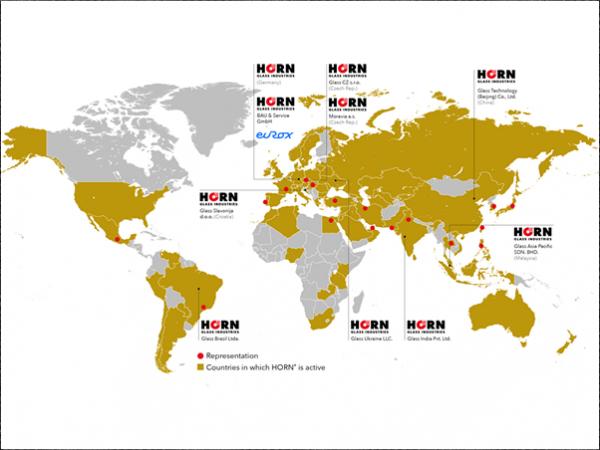

Products by HORN® Glass Industries stand for quality and reliability. HORN® customers all over the world appreciate this claim.

The furnace is designed in appliance with the most advanced technology and a maximum melting output of 290 t/d to produce either 290 t/d flint or amber glass or 280 t/d green glass.

The Liverpool City Region will benefit from £54 million investment to revitalise its glass industry and support the region’s economic recovery.

The awards, now in their seventh year, will take place this year virtually on 12 November and will again celebrate the achievements of the glass industry and its supply chain.

This innovative partnership will allow Eastman to satisfy the increasing demand for superior low-iron glass products.

HORN® Glass Industries will show you a film of how a glass melting plant grows, exhibit 24 products and support the technical lectures in the MELTING session on Tuesday, October 27, 2020 as sponsor.

The Belarusian company JSC "Grodno Glassworks" Elizovo Branch has appointed HORN® Glass Industries for the construction of a modern end fired furnace with a maximum capacity of 180 t/d.

What needs to be considered when using infrared thermometers, IR cameras and our new glass inspection system in different glass applications?

Even in the segments that were hardest hit by the coronavirus crisis the indicators are looking more positive again.

The fire-resistant glazing in the frameless system POLFLAM® BR, classified as EI 60. POLFLAM® glass, was also used for the fire-resistant doors in the staircases and is a definitive architectural feature of the building.

HORN® Glass Industries AG offers customer proximity and short response time on the global market.

Six trainees will be joining the workforce of HORN® Glass Industries AG this year.

Şişecam Group gets approval from shareholders to unite all operations under a single entity

This year in April HORN received the order for the repair of furnace 1 for the plant in Steinbach am Wald, which is an 82.8 m² end fired furnace.