Others also read

As the revised EPBD reshapes Europe’s energy performance landscape, this article explores what the new requirements mean in practice for windows, insulating glass units (IGUs), and the future of measurable façade performance.

On February 25, the European Parliament’s ENVI and IMCO committees voted on the agreement of the new End-of-Life Vehicles Regulation.

Glass Futures has completed its first alternative fuel trials campaign, demonstrating at industrial scale the viability of biofuels, electric melting and hydrogen to accelerate glass sector decarbonisation.

The Fenestration and Glazing Industry Alliance (FGIA) has updated the Aluminum Material Council (AMC) portion of its site with webpages covering aluminum-focused sustainability.

Thiele Glas enhances its quality control with the installation of the Temper Scanner by Viprotron.

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

The GGF has welcomed the Irish Government’s new energy upgrade grants, highlighting the strong commitment to windows and doors as a key driver of home decarbonisation.

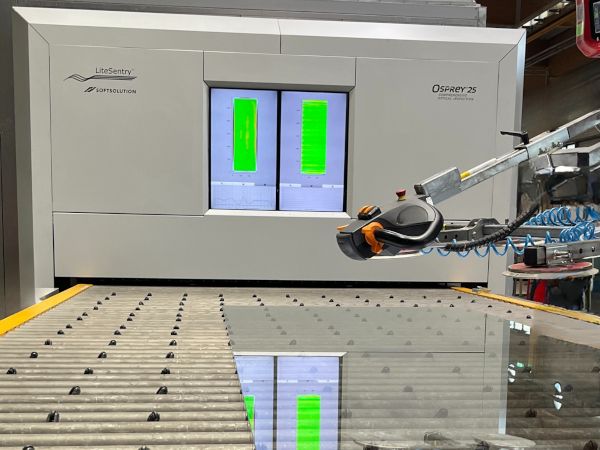

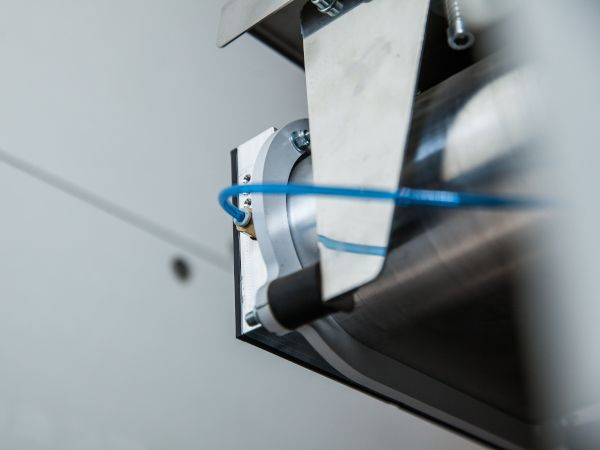

LiteSentry - Softsolution - Strainoptics will present their latest innovations in glass quality inspection at the 2026 Building Envelope Contractors (BEC) Conference.

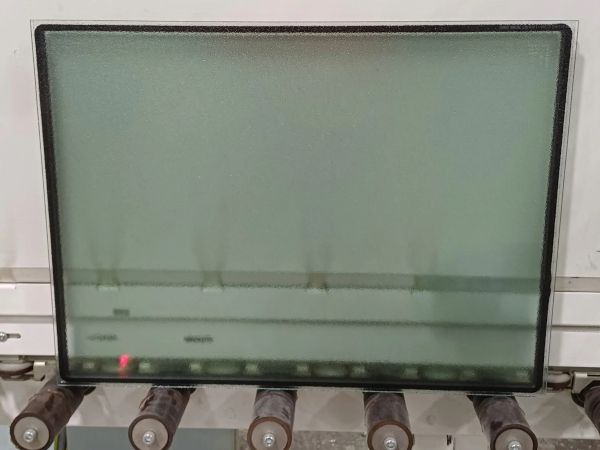

Project Scope: Inspection for All Types of Distortion, Anisotropy, Edge Stress, and Surface Quality.

New Group CEO brings 25 years of industrial automation leadership to global glassquality companies

Sparklike, a global leader in non-destructive gas measurement solutions for insulating glass units (IGUs), announced the appointment of Sasu Koivumäki to its Board of Directors.

The Circularity Frontiers Summit on Glass will bring students, researchers and industry professionals together in Koblenz in July 2026 to rethink the future of circular glass systems.

As sustainability expectations rise, installers are discovering that responsible recycling can be both compliant and cost-neutral.

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

Using the wrong waste collector could put your business at risk. FENSA highlights why installers must look beyond quick and cheap disposal options.

This year marks the 10th anniversary of Sparklike Laser Portable™, a major milestone in the development of non-destructive gas measurement for insulating glass units.

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

Saint-Gobain has once again demonstrated its strong commitment to sustainability by being recognized among the world’s leading companies in climate action by CDP.

A major step forward for sustainable glass manufacturing: a new AI-powered digital twin project is set to accelerate decarbonisation and transform how the industry optimises its processes.

NSG Group is proud to announce its participation as a founding member of ResponsibleGlass, a newly established global initiative promoting sustainability in the glass industry.

The three EU-funded projects H2GLASS, EVERGLASS & GIFFT invite you to participate in our joint webinar about the decarbonisation of the glass industry.

Saint-Gobain Glass is taking a major step toward low-carbon manufacturing with successful trials of locally produced biomethane in flat glass production.

LiteSentry – Softsolution will participate in Eurasia Glass Fair 2025, held from November 15–18 at the TÜYAP Fair and Congress Center in Istanbul.

Sparklike Laser Integrated™ is a fully automated, non-destructive gas measurement system designed to be integrated directly into insulating glass (IG) production lines.