Others also read

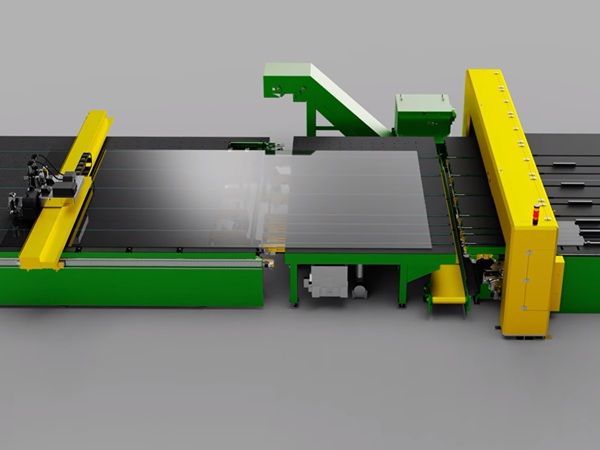

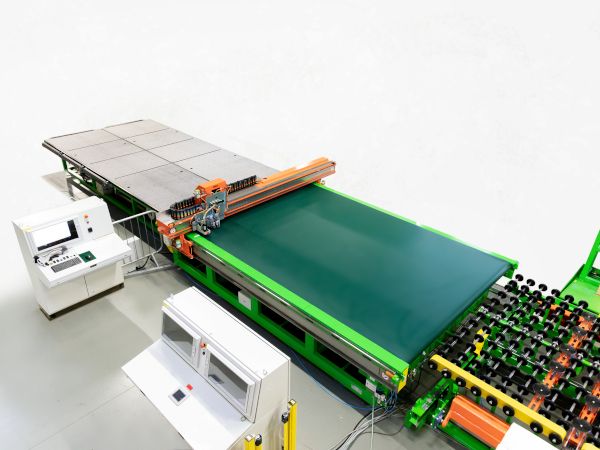

Hegla has released a new video showcasing the ProLam Neo LSR, its fully automated, high-performance cutting solution for laminated safety glass.

Innovation meets opportunity. The Start-Up Zone at glasstec puts emerging glass technologies on a global stage.

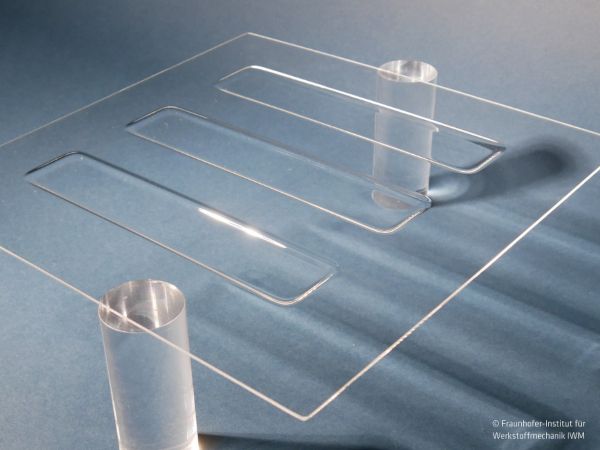

Tobias Rist of Fraunhofer IWM explains how an innovative laser process enables precise glass shaping, new structures and improved load-bearing performance for architecture and industry.

A smart solution for lighter, slimmer, and more efficient insulated glass units.

HEGLA is expanding its portfolio by entering the field of wet glass machining through the acquisition of RS technology, strengthening its capabilities in advanced glass processing and automation solutions.

Its recent investment in the innovative LiSEC SRP-A system underscores their shared commitment to digitalisation and greater efficiency.

TUROMAS supports Grupo Tecnovidrio's evolution with technology, commitment and a vision for the future.

NorthGlass has successfully delivered a fully automated smart manufacturing line for a key client in Vietnam, enabling high-precision, high-volume production that meets the demanding standards of global home furnishing brands, including IKEA.

Be part of the world's leading trade fair for the glass industry from 20 to 23 October 2026.

With agil tr, electa, taktika, and easyline, CMS Glass Technology plays its winning hand: a true four aces combination of compact, flexible, and user-friendly solutions, never compromising on quality.

Austrian window manufacturer Felbermayer has invested in turnkey LiSEC technology to achieve fully automated, high-quality insulating glass production.

From 16 to 19 September, TUROMAS took part in the latest edition of VITRUM 2025, the international glass technology exhibition held at Fiera Milano Rho (Italy).

In 2025, TUROMAS celebrates four decades of activity, establishing itself as an internationally recognized family business in the design and manufacturing of smart machinery for the storage, loading, and cutting of monolithic and laminated glass.

The LiSEC Group is pleased to announce that the products of Schraml Glastechnik GmbH will be marketed under the LiTROS brand from now on.

A head start through networking and innovation: glasstec in Düsseldorf has been the world’s leading trade fair for the international glass industry for decades.

With glasspex INDIA and glasspro INDIA, one of the world’s most dynamic glass markets is opening its doors to innovation, investment and networking.

Innovation and reliability drive Crielec Vidres’ success in the double glazing sector with TUROMAS by their side.

Balancing daylight and design with bird safety is a growing challenge in modern architecture.

HEGLA showcases smart glass solutions at Vitrum 2025 in Milan.

On 1 September 2025, Daniel Feische will move to the Occupational Safety & Health and Glass Technologies portfolios as the Director and will be fully responsible as of 1 December.

From June 12 to 14, the CMS facility in Zogno (BG) hosted the CMS Open House – three days dedicated to innovation in glass processing, featuring live demonstrations, technical insights, and valuable meetings with customers and partners.

From July 16 to 18, the Citibanamex Centre in Mexico City will host a new edition of Glasstech Mexico, the most important event for the glass industry in Latin America.

The cutting of thin glass is extremely demanding! That’s why HEGLA has designed a Galactic float glass cutting system specially for the needs of thin glass.

Traditional Egyptian Glass Techniques realized by Cutting-Edge Software.

Unlock the potential of your existing machines with our innovative retrofits. These five features allow you to benefit from our continuous development and make the LiSEC machines in your machine park future-proof.