Others also read

Thiele Glas enhances its quality control with the installation of the Temper Scanner by Viprotron.

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

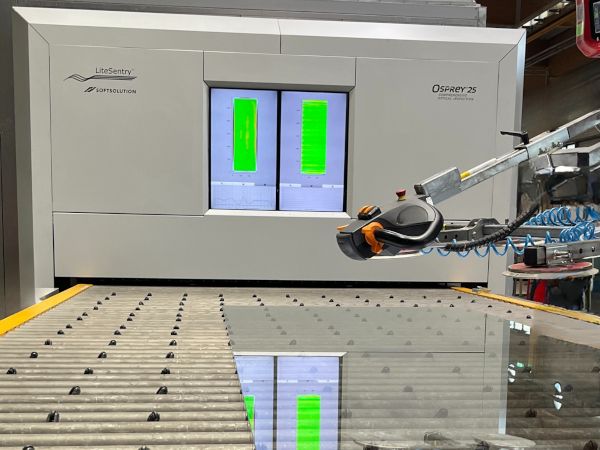

LiteSentry - Softsolution - Strainoptics will present their latest innovations in glass quality inspection at the 2026 Building Envelope Contractors (BEC) Conference.

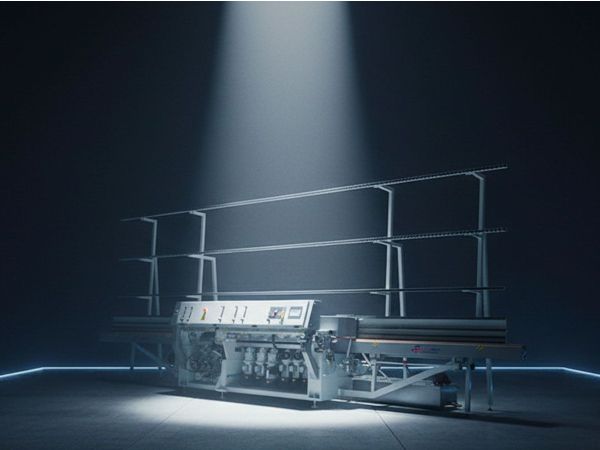

The ultimate glass lamination machine to laminate with EVA, PVB and SGP.

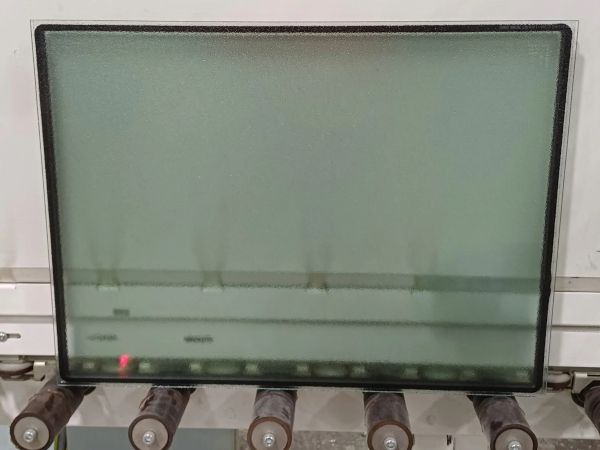

Project Scope: Inspection for All Types of Distortion, Anisotropy, Edge Stress, and Surface Quality.

New Group CEO brings 25 years of industrial automation leadership to global glassquality companies

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

Zero worries. Maximum productivity.

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.

HEGLA is expanding its portfolio by entering the field of wet glass machining through the acquisition of RS technology, strengthening its capabilities in advanced glass processing and automation solutions.

NorthGlass has successfully delivered a fully automated smart manufacturing line for a key client in Vietnam, enabling high-precision, high-volume production that meets the demanding standards of global home furnishing brands, including IKEA.

LiteSentry – Softsolution will participate in Eurasia Glass Fair 2025, held from November 15–18 at the TÜYAP Fair and Congress Center in Istanbul.

LiSEC is meeting challenges and emerging trends with innovative concepts and custom solutions.

R.C.N. Solutions celebrates its long-standing partnership with Vetreria Ascolese — a company that combines tradition, innovation, and excellence in glass manufacturing.

Scm Group wins the SMAU Innovation Award for “Smart Spindle” — an AI-powered system that predicts faults, cuts downtime, and boosts efficiency.

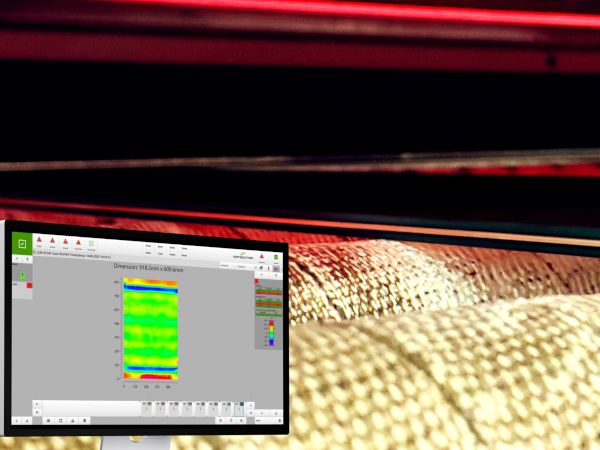

Automation and precision are redefining flat glass processing. In this expert article, Mika Eronen of Global Glass Specialists explains how dual-metric scanning is transforming quality control and boosting yield across the industry.

Visit Booth #9048 to meet the experts from LiteSentry, Softsolution, and Strainoptics and experience live demonstrations of cutting-edge inspection systems.

When perfection matters, even the slightest bow counts. The Bow Sensor keeps your production line running smoothly with real-time precision and total control.

With its new plant in Port Talbot, Press Glass UK is consolidating three locations and boosting efficiency and growth thanks to LiSEC automation.

Viprotron has unveiled its latest innovation — the Bow Sensor, a cutting-edge solution designed to detect and control glass deformations, or “bows,” early in the production process.

At GlassBuild America 2025, VIPROTRON will demonstrate how its latest inspection technologies are transforming industrial glass production — optimizing measurement, control, and quality across the entire production line.

At GlassBuild America 2025, Glaston showcases its latest innovations in glass processing, emphasizing smart automation, energy efficiency, and production flexibility.

For over 50 years, Schiatti Angelo has been designing and manufacturing glass processing machinery for the international market, delivering the perfect synthesis of technological innovation and energy sustainability.

Curious to see how the RCN’s full automatic laminating machine works? Watch out for the new video of LIA – laminating integrated automation.