Others also read

On November 3, 2023, the new Engineering Center was opened at the LiSEC site in Seitenstetten.

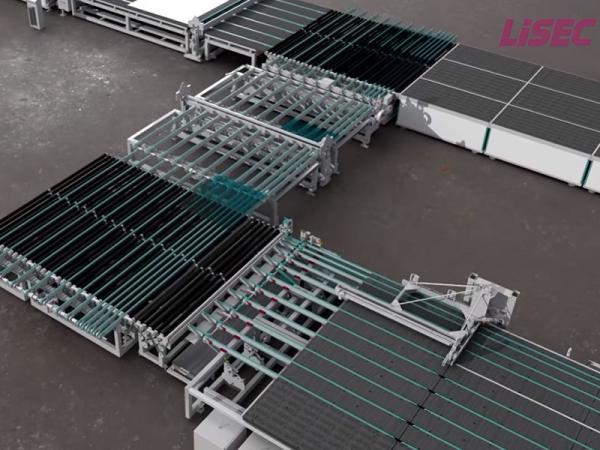

Upgrade with great added value: The systron face-to-face setup plus storage systems significantly increase Arbonia's efficiency

LiSEC will be showcasing its cutting-edge glass processing technologies and state-of-the-art machinery at booth #2831.

In this video, Brad Bartley and Lindsey Merryman at Consolidated Glass in the US are sharing their and their team's experiences working with the Glaston laminating line.

A partnership with LiSEC for a greener future

Predari Vetri's journey to customer-centric excellence and innovation in insulating glass production.

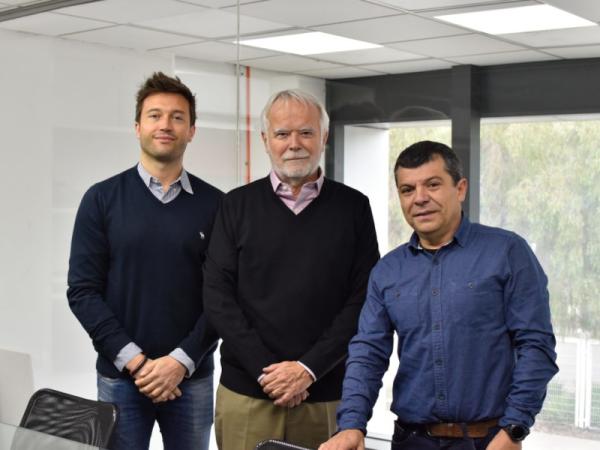

A decades-long partnership of quality and innovation in the Chilean glass industry

A six-month journey of success and innovation, unveiling new projects and achievements.

At the Turomas booth at Vitrum, the company presents the audience with the most cutting-edge innovations in technology for glass storage, cutting, and loading.

Press Glass carried out the project in collaboration with Staticus, delivering more than 15,500 m² of glass.

Pioneering a new era in glass manufacturing, Nashville Tempered Glass is excited to be one of the first in the US to launch the innovative Surface 1 laser etched bird-friendly glass this August.

TUROMAS’ innovative ACR decoats different protective plastics and resins that require removal during glass-cutting.

Schraml Glastechnik GmbH, a member of the LiSEC Group, is proud to announce the launch of the 8th generation topDRILL glass drilling machine.

New color options, sizes and applications protect birds without compromising views.

Laminated Glass Production with LiSEC Machines: Speed Assembling Mode

How high-quality insulating glass is produced with LiSEC machines in Nord Rostock.

Pujol reinforces its position in the Indian market with a new Pujol 100 PVB+ installed in Vitra India Glass PVT. Ltd

The LiSEC PlusLam is a laminated glass line equipped with sophisticated machines and sophisticated lamination technology.

The one-by-one mode is especially suitable for the series production of small glass at high speed with only one person. In addition, there is less foil waste due to the waste optimisation.

The new software has been specifically developed to streamline the management of both vertical machines and the latest CMS cutting tables.

NorthGlass' Glass Deep Processing Division played a vital role in transforming the original factory buildings into high-end office spaces, showcasing their exceptional craftsmanship and contributing to the project's success.