Others also read

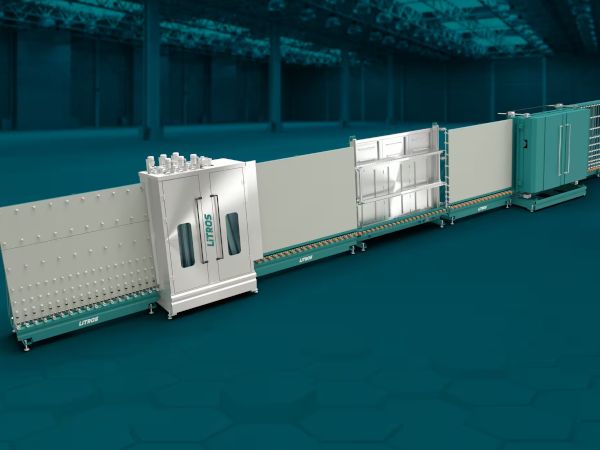

The vertical LiTROS insulating glass line offers a good solution for the efficient production of insulating glass units with rigid spacer frames.

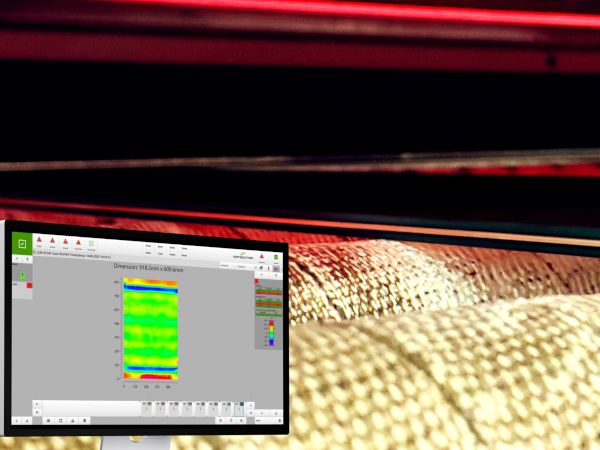

Thiele Glas enhances its quality control with the installation of the Temper Scanner by Viprotron.

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

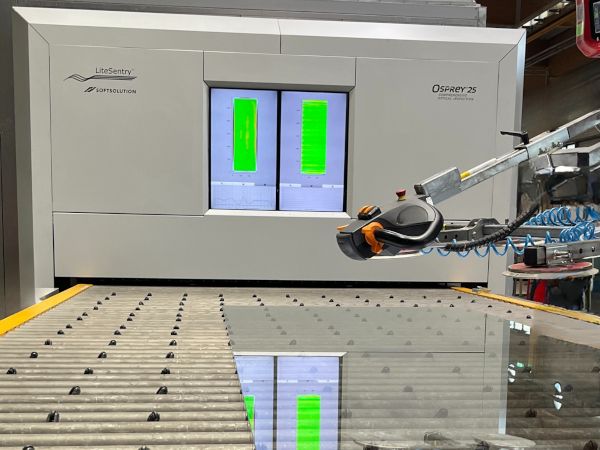

LiteSentry - Softsolution - Strainoptics will present their latest innovations in glass quality inspection at the 2026 Building Envelope Contractors (BEC) Conference.

Project Scope: Inspection for All Types of Distortion, Anisotropy, Edge Stress, and Surface Quality.

New Group CEO brings 25 years of industrial automation leadership to global glassquality companies

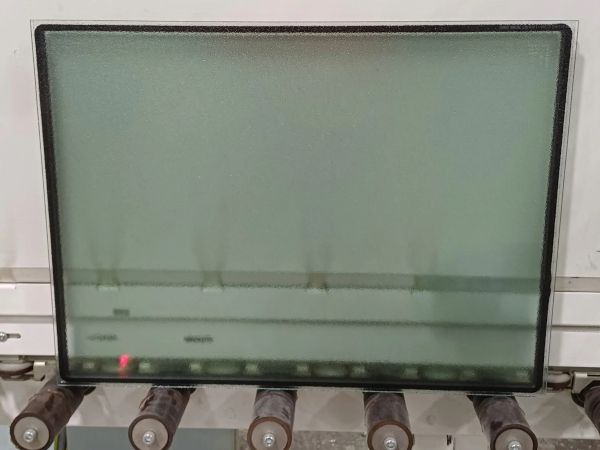

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

Chongzheng Shengda Glass opts for the first 8 × 3.3 metre TPA line from LiSEC.

When production gets more complex, strong partnerships make it sustainable.

As 2025 draws to a close, it’s a good time to reflect on business. We know for most glass processors, this has not been the easiest year.

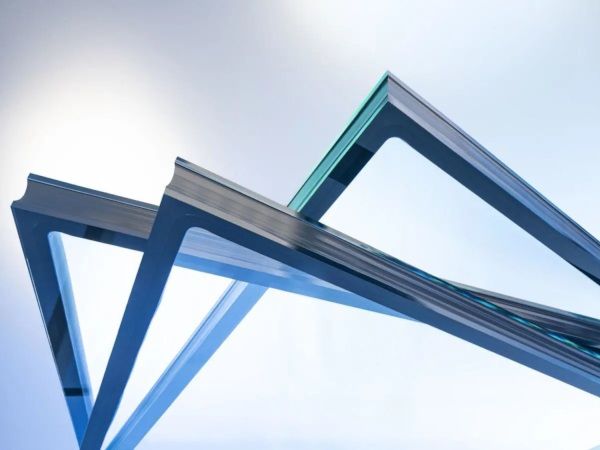

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.

Its recent investment in the innovative LiSEC SRP-A system underscores their shared commitment to digitalisation and greater efficiency.

Discover how automated TPA application ensures accuracy, speed and reliable processing – even in large-format production.

The 2025 edition of GlassBuild America has concluded in Orlando, marking a record-breaking year for North America’s leading glass industry exhibition, which welcomed the highest number of exhibitors and visitors to date.

LiteSentry – Softsolution will participate in Eurasia Glass Fair 2025, held from November 15–18 at the TÜYAP Fair and Congress Center in Istanbul.

From the GlassBuild 2025 show floor in Orlando, Forel & Quanex are highlighting the innovative collaboration that is bringing automation and spacer performance to the next level.

Forel introduces a new manufacturing solution for Triple Thin IGUs with Flexible Spacer, combining advanced automation, precision, and efficiency for next-generation insulating glass production.

New model FG for fast grinding and simultaneous edge seaming.

Automation and precision are redefining flat glass processing. In this expert article, Mika Eronen of Global Glass Specialists explains how dual-metric scanning is transforming quality control and boosting yield across the industry.

Visitors can find the Forel team at Booth #18085 (South Building), where they will share the latest updates on Forel’s advanced glass processing technologies, 100% Made in Italy.

Visit Booth #9048 to meet the experts from LiteSentry, Softsolution, and Strainoptics and experience live demonstrations of cutting-edge inspection systems.

When perfection matters, even the slightest bow counts. The Bow Sensor keeps your production line running smoothly with real-time precision and total control.

The UK Glass & Glazing Collective gathered at Westminster to present a united industry voice and outline key policy priorities shaping the future of the UK glass sector.

With its new plant in Port Talbot, Press Glass UK is consolidating three locations and boosting efficiency and growth thanks to LiSEC automation.