Date: 12 September 2018

As a committed end customer supplier, this owner-operated company places special value on reliable service. Managing Director Leo Löffler joined this family-owned company in 1984, becoming the third generation to lead the company. He and the entire LÖWE team are convinced that top-quality products can only be created in close cooperation with expert technology partners. With A+W, he makes no compromises.

LÖWE supplies customers in an area of approximately 100 km – almost the entire Rhine- Main region. In total, this company in Kleinwallstadt has more than 35,000 customers, approximately 70 % of these are individual home builders. Another important customer segment is developers, many of whom have worked with LÖWE for years.

Ten well-organized LÖWE installation teams ensure that even the most demanding products and oversized elements are installed professionally and quickly. With more than 70 employees, LÖWE is an important employer in the region and, thanks to its training program, it attracts a steady stream of junior employees.

The sympathetic lion as brand mark has outstanding recognition value and is placed consistently in the region – on the company’s vehicles, on posters, but also on TV advertisements and in online advertising and sport sponsoring: the company is self-aware and maintains a high profile.

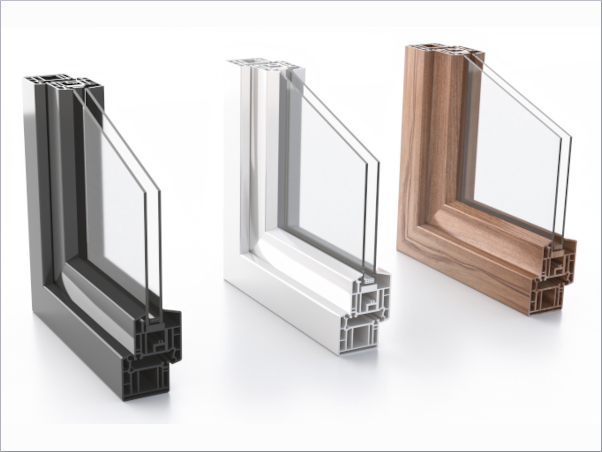

Attractive showrooms at two company locations in Kleinwallstadt and in Rödermark offer prospective customers a wealth of ideas for design possibilities. They provide insight into the company’s fascinating product spectrum and allow properties such as the quality of profile surfaces and hardware and the high-quality security equipment to become “palpable.”

In its catchment area, LÖWE is the only certified manufacturer of burglary-resistant PVC windows and window doors to be included in the manufacturers’ index of the police criminal prevention commission. Resistance class RC 1 N is a LÖWE standard since 2013.

State-of-the-art system technology – intelligent process control

“High-quality products,” explains Managing Director Leo Löffler, “can only be produced in cleverly organized, networked production environments using the best technologies.” Controlled by state-of-the-art industry software, LÖWE production uses only premium machine technology, usually from Rotox.

Paper is nowhere in sight: A+W Cantor’s production monitors and barcode scanners reliably deliver the right information at the right time, triggering real-time status messages and automatically initiating processes throughout production. The barcode labels include all the data necessary to handle all production processes reliably and quickly.

LÖWE networks all production with A+W Cantor Production planning and control systems, a powerful database-based solution that smooths out production thanks to its comprehensive approach – from delivery and storage of the profiles and hardware to shipping control.

In addition to networked control of all machines, this includes especially continuous information management at each automatic and manual workstation. Integrated materials management ensures that even during order entry, it is clear whether all parts required for production are in stock or whether a re-order will be necessary.

This creates a smooth production flow and an accurate forecast of the delivery date. Since the introduction of A+W Cantor, it is a matter of course for the LÖWE employees in production that all parts are available precisely where they are needed.

As in earlier times, the electronic data processing system does not look first and foremost at individual machines, but rather at the entire interaction between the machines, transport lines and buffers, and manual workstations. Most products are produced completely automatically and controlled intelligently through production.

Frame and glass buffers channel the components based on the bar code in real time to assembly and glazing. Nobody has to look for anything, no employee carries stacks of paper or material through the production hall.

Even at manual processing stations, information is provided by A+W Cantor CIM monitors; true-to-scale graphics help the workers with manual steps. According to Business Manager Ralf Klein, “Today, we have no workstations without a direct machine connection or A+W Cantor CIM workstation.”

Production control is coupled seamlessly with the A+W Cantor Enterprise system, the business part of this comprehensive ERP solution. All job data is available across the company shortly after order entry. Status reports are sent from production to the A+W Cantor Enterprise system to ensure maximum transparency.

Control instructions for production are transferred from the Enterprise system in real time – individual production users see only what is needed for their work. Thanks to this high-tech system, each workstation can be configured individually.

The feasibility check: can we build this?

In 2009, Leo Löffler decided to replace older software that had reached its limits with the comprehensive A+W Cantor solution. The changebrought many advantages.

In 2009, Leo Löffler decided to replace older software that had reached its limits with the comprehensive A+W Cantor solution. The changebrought many advantages.

Yet, if you ask Leo Löffler and Ralf Klein what led to the decision, they will say that it was the integrated feasibility checks built into A+W Cantor. “Again and again,” according to Klein, “employees used to come to me shaking their heads, telling me that items entered could not be built.

We couldn’t go on like that any longer, and it changed suddenly with the introduction of A+W Cantor: the integrated automatic feasibility checks are absolutely secure – assuming that the master data has been created correctly. This requires some effort during implementation. But for this, you are rewarded with intelligent functionalities that save a lot of time and money.”

Top of class, not cheap goods

In its core market with the critical sales region Rhine-Main, LÖWE Fenster enjoys an outstanding reputation as a premium supplier that provides top quality, expert advice, and perfect services. Its success has proven this company in Kleinwallstadt correct: demanding customers rely on the security that the regionally oriented company offers even years after installation, e. g. for maintenance and repairs.

An expert, experienced employee team that is open to high-tech production processes and consistently uses state-of-the-art industry software offers the best prerequisites for succeeding on the current difficult market, both now and in the future. Leo Löffler declares, “You’d look in vain for cheap goods here. We offer the highest quality at fair prices, and our customers know how to appreciate that!”

600450

600450

Add new comment