Date: 23 March 2022

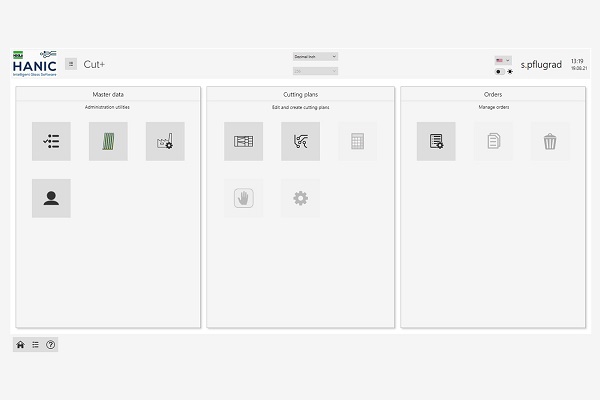

Normally, one update follows the other to bring software up-to-date. But HEGLA-HANIC from Bochum, Germany, does things differently. The company is now offering Cut+, a new program for cutting table organisation and management that relies on a range of new functions and is a completely new version.

“You can use updates to keep any software current,” explained Managing Director Dr Jan Schäpers of HEGLA-HANIC. “But at some point you should take advantage of the opportunity to re-think proven programs and prepare for the future.” Cut+ is based on the standards of .NET Core, the Microsoft development environment, which ensures that the software can be extended from the Microsoft pool with little effort at any time.

Intuitively register customer orders and create items

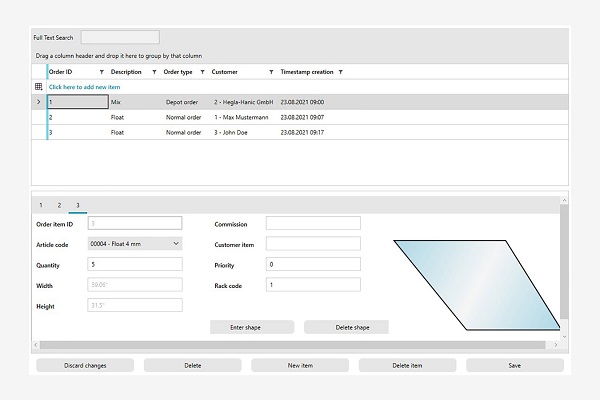

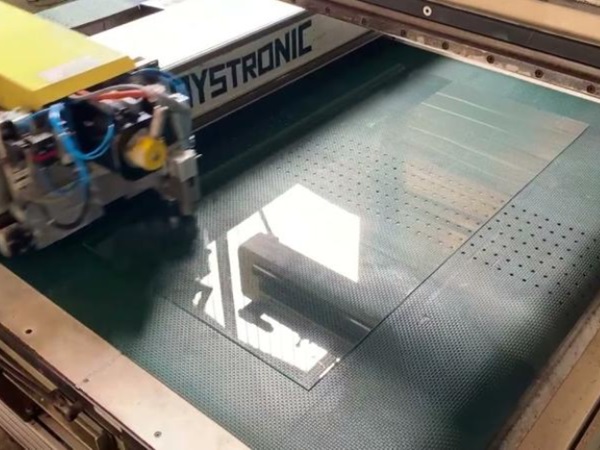

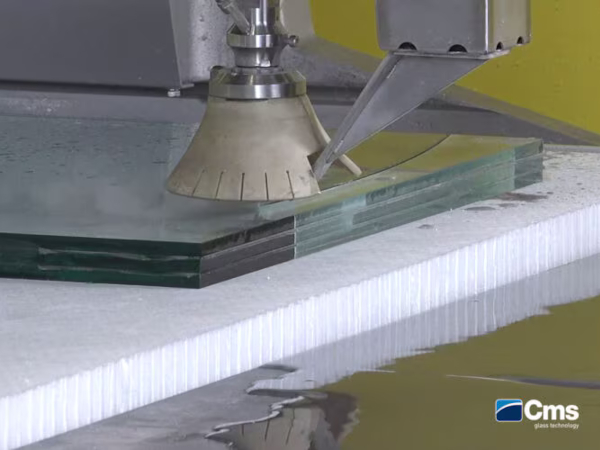

Cut+ is designed to intuitively manage and organise individual cutting tables. Its core functions include the technical registration of customer orders with all parameters to ensure that they are available for further processing. Orders can be registered by importing Excel .csv files, for example. It is also possible to register the data directly at the cutting table, on an office computer as a step in work preparation, or in the form of an order acceptance. If keypads are not available, a touchscreen can be used instead. A live editor immediately displays the registered geometry to the operator for a plausibility check. Alongside a .dxf import option, a shape catalogue intended to make work on complex geometries easier is stored in the software. Users can intuitively add the shapes they create themselves to the catalogue.

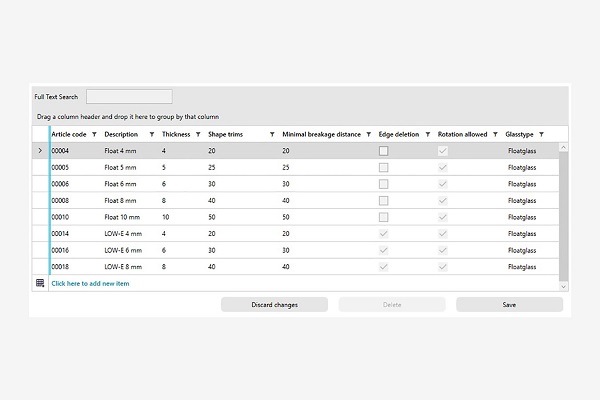

The integrated item management system saves recurring products from the product range to simplify future orders.

Waste-optimised cutting plans at the press of a button

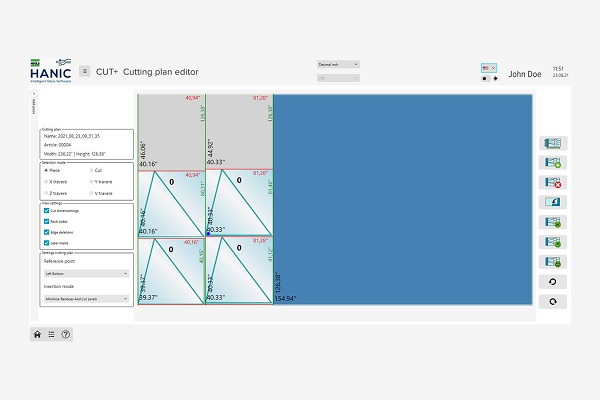

As soon as all the orders are in the system, a waste-optimised cutting plan can be requested and created, and the glass can be arranged to ensure that as much glass area as possible is used. The software takes break-out allowances into account, as well as decoating contours, grinding additions and surrounding pane shapes. “Operators remain fully flexible,” emphasised Dr Jan Schäpers. “Panes can be exchanged or shifted on the plan via drag & drop. It is almost always possible to make amendments.” If required, the cutting plans can be printed out and made available for in-company process organisation. If the glass to be processed is not on hand in the warehouse, the optional Cut+ warehouse management extension will trigger an alert.

Paper, labels and laser marking are supported

For internal operations that are organised with labels instead of paper, the software offers a label editor. The visual placement of the customer logo and data on the labels can be manually specified if desired. Alternatively, this can be done automatically when the dataset is called up from the customer file. If you plan to switch to laser marking in future, the software is already compatible with the control and data transfer functions of most systems.

Open interfaces in accordance with OPC/UA

Open interfaces in accordance with OPC/UA are the technical basis that enable the software to be used with almost any cutting table from almost any manufacturer. If your system is not prepared for this, HEGLA-HANIC will adapt the software to your specific needs.

“We are proud of the new software and pleased that our team has very successfully taken this step,” said Dr Jan Schäpers. “Alongside various extensions and options, we can also provide a Cut+ trial version so our customers can form their own impression of our new software.” It is still possible to connect to the Shop-Floor Assistant app from HEGLA New Technology and the HEGLA-HANIC Cockpit.

Cut+ supports a high number of different languages and units of measurement, which operators can select themselves. Inclusive updates are regularly provided and they continue to support earlier versions of the HEGLA-HANIC software.

600450

600450

Add new comment