Date: 30 August 2018

Glasstec is an unmissable event for all the players of the glass business. Forel, always working on new and more advanced solutions for flat and insulated glass processing, has been attending Glasstec for more than 40 years.

Also this time, will attend the event to meet customers, exchange information with other players and, of course, showcase the best products of its range.

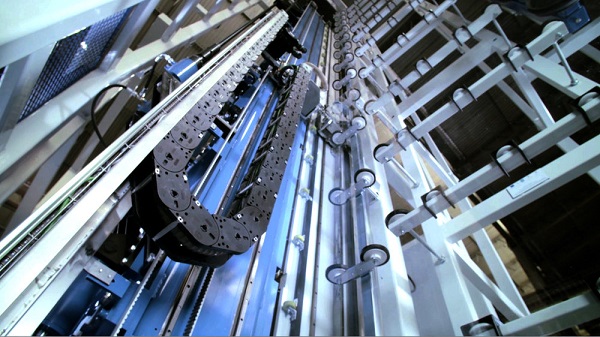

At Forel Booth (Hall 16, Stand A21/A41) visitors will have the possibility to look at a “No Limits” Insulating Glass line, from the new range of IGU lines designed to “go beyond” Jumbo size.

To answer to the growing request for larger glasses, the “No Limits” range can process panes up to 15 meters long and 3.30 meters high, with a load capacity per linear meter that reaches 350 kg for the single pane and 600 kg for the assembled panes.

To process such large formats, Forel has also developed a number of special applications that allow to better control and manage possible glass bows (even of centimeters) in every step of the insulating process.

The development of the “No Limits” range will also allow to upgrade the “standard” IG lines, for example with the innovative technology to straighten up any glass planarity unevenness in the coupling press, the continuous and dynamic dosing circuit in the sealing robot, the new glass displacement driving system and many other features.

The “No Limits” line showcased at Glasstec will be a 9000m x 3300mm line, composed by washing machine, quality scanner, frame application and inspection station, turning conveyor, gas filling coupling press and sealing robot complete with pumping system.

Besides the “No Limits” IG line, Forel will display a Vertical Cutting Line for Laminated Glass and a Vertical Line for Flat Glass Processing.

The vertical cutting line, equipped with two cutting bridges and an impressive turning section, can process Jumbo size sheets and cut on the three axes, X, Y and Z. Each bridge consists of two opposing engraving carriages and two breaking bars to cut and open the glass sheet along its entire height, the split being supported by a special motorized system. A unique line that continues to distinguish Forel as a world leader in providing the highest quality technology.

The vertical line for flat glass processing (for seaming, edging, drilling and milling) is composed by an edging machine, a drilling & milling machine and a washing machine. A processing line that the international market appreciates more and more for its productivity and remarkable reliability, as evidenced by the ever increasing success in sales.

Glasstec will be also the opportunity for Forel to anticipate the latest innovations on its systems for handling, storing and sorting glass inside the factories: in fact, in addition to the solutions already developed in this field, other new solutions for the logistics of the finished products will be available soon.

“Coming back to Düsseldorf is always a special emotion, but this year Forel will attend the exhibition with a special enthusiasm. We are glad to announce the new enlargement of our factory: 10.000 square meters of productive area will be added to the actual 20.000 square meters of the existing plants, by the end of 2019” says Fortunato Vianello, Founder and President of Forel.

“The enlargement is an important investment, a decision taken with the awareness that our commitment is rewarding us and will bear fruit. We are a growing company, able to deserve the loyalty of the “old” customers and, at the same time, to keep on convincing many new ones. This is possible thanks to the quality of the product, our reliability, the investments made in our Service Dept. and to our philosophy: listening to the customers, trying to understand market trends, developing new solutions”

600450

600450

Add new comment