Date: 6 March 2012

Bystronic glass has recently launched the comfort’line to the European Market designed for the production of insulating glass. Bernhard Schmitt, Managing Director of Bystronic glass in Neuhausen-Hamberg, Germany states that, "Working with the line is comfortable, quick and precise providing the ideal entry into solution for industrial insulating glass production". He explains "At the same time, the comfort’line allows us to reach out to customers who are searching for an inexpensive opportunity to expand their insulating glass production capacity." 800 gas-filled insulating glass units can be produced in rectangular or shaped formats on the quick line per shift..jpg)

"The great advantage of the comfort’line is its simple handling and the uncomplicated operator guidance", Bernhard Schmitt comments knowing exactly what is important for the sector. The base model of the insulating glass line consists of three elements: a glass plate washing machine, a station for the visual monitoring of the glass plates complete with subsequent frame positioning and an insulating glass press. With its three separate brush-pair drives, the washing machine ensures great results on sheets up to 15 millimetres thick. Its external, chainless brush and transport drive promises additional convenience and reassurance. The high-contrast, well-lit inspection area complete with coloured signal lights provides a quick and reliable inspection facility for glass plates. The automatic beam setting for vertical positioning of the frame means the spacer can be applied precisely, even by inexperienced users.

Precise assembly of the units with gas filling

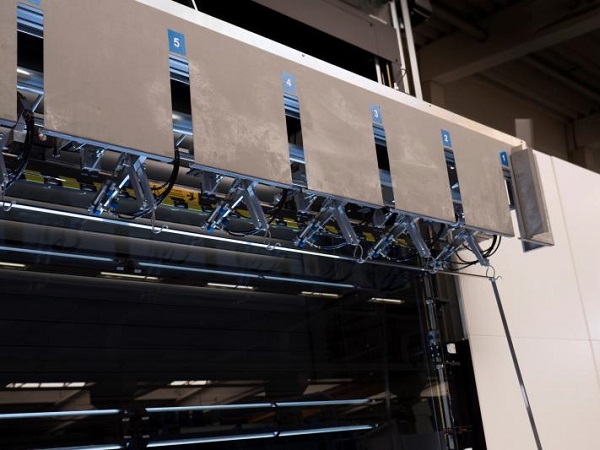

The core of the comfort’line is the insulating glass press that assembles the insulating glass units, fills them with inert gas and presses them precisely in one single processing step. "This works just as well with non-stepped, rectangular units as with shaped formats with steps on up to three sides and works with both double and triple insulating glass units: the customer has the choice – even when it comes to the spacer material", explains Bernhard Schmitt. Inert gas filing is completed quickly, efficiently and at a high level directly into the units, while adjustable press plates ensure precise and uniform insulating glass pressing. .jpg)

The line is rounded off with a tilt table to discharge the units ready for the subsequent manual standard sealing. It goes without saying that the equipment for the manual sealing – the rotating sealing table and the manual sealing unit – are also available from Bystronic glass.

For those who do not wish to seal manually the line can be expanded with a conveyor and a sealing machine. Bernhard Schmitt explains: "With the aid of the compact’sealer sealing machine, the customer can upgrade their comfort’line from an entry-level solution for industrial glass production to an automated production line. The main advantage of the compact’sealer is its precise dosage function which determines precisely the joint depth and then subsequently applies the exact volume of sealing material required. This level of precision cannot be achieved when sealing manually."

At the request of the customer, the comfort’line can also be expanded with machines for the production of spacers: a butyl extruder for the double-sided coating of rectangular and shaped frames with buytl; a frame bending robot and a desiccant filling station represent ideal additions to the comfort’line.

comfort’line technical data at a glance:

Output: up to 800 gas-filled insulating glass units per shift

Transport speed: 48 m/min

Working height: 2.70 m

Minimum glass format: 190 x 350 mm

Maximum glass length: 3.50 m with gas-filling / 4.50 m without glass filling

Thickness of the insulating glass units: 12-60 mm

Insulating glass types: Double and triple units

Rectangular and shaped formats

Stepping on between 1 and 3 sides

Website:

www.bystronic-glass.com.jpg)

About Bystronic glass

Bystronic glass is the competent and reliable partner for services, machinery, plants and systems in the glass processing sector. Bystronic glass supplies its well-proven machine technologies also in important areas of the photovoltaic industry. Bystronic glass is an international brand with globally operating companies that support their customers on site and through own sales and service companies. Since 1994, Bystronic glass is part of the Conzzeta AG, a renowned Swiss industrial holding company.

Bystronic glass media contact:

Iris Minten

PR / Online Communication

c/o Bystronic Lenhardt GmbH

Karl-Lenhardt-Str. 1-9

D-75242 Neuhausen-Hamberg

Phone +49 (0)7234 601 120

Fax +49 (0)7234 601 114

iris.minten@bystronic-glass.com

www.bystronic-glass.com

Bystronic glass sales contact:

E-Mail: sales@bystronic-glass.com

For the contact details of Bystronic glass global representatives please visit www.bystronic-glass.com

Add new comment