Date: 25 January 2008

Among the most important new products are a multi-functional bonding table, a variable light tunnel and a professional, portable bonding unit.

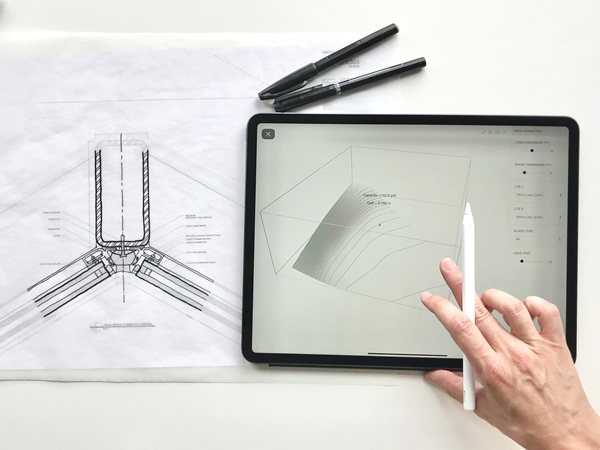

The VERIFIX bonding table is an innovative piece of equipment allowing easy and efficient bonding of metal to glass. Whether in furniture or glass door production: With this device, developed and produced by Bohle, metal bonding parts are positioned to flat glass with an unsurpassed repeat accuracy. Even different metal parts, e.g.two hinges and a lock, can be mounted in just one operation. Any shape and size of glass pane is suitable to be worked on. The load capacity of up to 150 kg also allows extraordinarily large and thick glass panes to be processed. If required, the bonding table can be expanded and integrated into existing production lines. A further advantage: The new technology minimises the amount of adhesive used and consequently reduces required cleanup at the bonding sites. An ideal complement to the bonding table is the new VERIFIX light tunnel. Four groups of UVA lamps can be switched on variably so that curing occurs optimally with illumination targeted exactly where needed. At present, the homogeneity of illumination combined with longer service lives of the UVA lamps is unique.

With the professional bonding unit, Bohle provides a totally new, highly flexible and precise unit ideally suitable for industrial UV-bonding. Whether for portable use during production or for quick, top-quality bonding on site, this innovation is ideal. Wherever a pneumatic connection is available, metal parts can be precisely positioned and bonded to glass – with high repeat accuracy. Applying the adhesive is also much easier: The innovative vacuum technology allows trouble-free application of adhesive – without the formation of air bubbles and, at the same time, reducing cleaning requirements to a minimum.

Optimal Coordination of Products  The technological leadership of Bohle in the field of glass bonding is based on profound, longtime know-how with the major advantage of expertise and experience from many different aspects of glass processing. Bohle not only offers adhesives, but all of the equipment needed for glass bonding as well. These include UV lamps, positioning aids and cleaning agents in addition to bonding systems for automation of bonding processes, surface protection systems and top-quality designer fittings. Additionally, Bohle offers transfer of know-how in the form of seminars and training sessions. Due to the close interaction of activities in development, all products are optimally coordinated with each other for top performance. Bohle's product range for glass bonding is the largest in the world. Thus, as a systems supplier, Bohle is the ideal partner to provide solutions for demanding, customer-specific requirements. This is true for individual jobs by glaziers as well as for automated production.

The technological leadership of Bohle in the field of glass bonding is based on profound, longtime know-how with the major advantage of expertise and experience from many different aspects of glass processing. Bohle not only offers adhesives, but all of the equipment needed for glass bonding as well. These include UV lamps, positioning aids and cleaning agents in addition to bonding systems for automation of bonding processes, surface protection systems and top-quality designer fittings. Additionally, Bohle offers transfer of know-how in the form of seminars and training sessions. Due to the close interaction of activities in development, all products are optimally coordinated with each other for top performance. Bohle's product range for glass bonding is the largest in the world. Thus, as a systems supplier, Bohle is the ideal partner to provide solutions for demanding, customer-specific requirements. This is true for individual jobs by glaziers as well as for automated production.

Continuous Development Work

It is both the goal and standard of Bohle to provide the customer with technically optimal solutions. By continually researching new high-tech materials, Bohle is always at the forefront. Fittings rank highly in the systems product range. It is especially important to the company that their lines of fittings have unique selling points which clearly set them apart from what the rest of the market has to offer. The new designs are developed in-house and transformed into serviceable products meeting high-quality standards. The company's relationship to glass as a material is traditionally of highest importance, but it is not all-exclusive. For example, Bohle is working on connections to wood as a material in order to develop totally new design approaches.

Proven Quality

Profound experience in the areas of glass, hardware and machinery are important cornerstones when developing new adhesives for glass. Thanks to Bohle's in-house laboratory capacities, the company is in a position to find bonding solutions for practically any bonding problem. Comprehensive product testing, both in-house and by external testing institutes, ensures that each adhesive performs with optimal safety and quality in everyday use. Close cooperation with scientific partner institutions guarantees highest standards in product development and quality control.

Comprehensive Advisory Services

At Bohle, applications technology serves as a link between the company and the customer. Qualified master glaziers and technicians advise customers in the planning, construction and follow-up of bonding projects. It is not uncommon that these close exchanges of information result in insights and solutions which not only benefit the customer and the company, but the entire branch as well. Beyond providing concrete, project-related advice, Bohle also offers seminars for beginners and professionals. These are held in the Bohle seminar centre at company headquarters in Haan, but can also take place at Bohle subsidiaries, at Glass Technical Schools or directly at the customer.

Add new comment