Date: 1 June 2012

Customers now can utilize ultra-thin glass without altering their existing production facilities, a major stride toward the commercialization of ultra-thin glass for next-generation displays and various other applications.

Ultra-thin glass, which AGC developed last year, offers excellent transparency, heat resistance and electrical insulation, as well as extra thinness and flexibility, making it ideal for next-generation displays, touchscreens and lighting equipment..jpg)

Ultra-thin laminated glass substrate

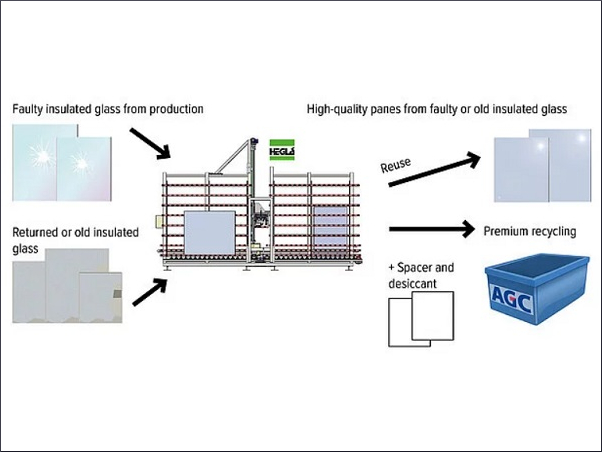

The roll-to-roll production method, which is currently under development, enables rolls of ultra-thin glass to be used conveniently in continuous strips during production. However, the method has required substantial alterations in production facilities to ensure proper handling of the ultra-thin glass. To overcome this need and thereby accelerate commercialization, AGC has now developed the technology to laminate ultra-thin glass onto approx. 0.5 mm carrier glass. The laminated glass substrate can be handled much the same as ordinary glass sheet (sheet-to-sheet method), enabling circuit formation and other processing of ultra-thin glass without having to alter existing production facilities.

Ultra-thin glass and carrier glass are laminated via a special bonding layer that makes the laminated substrate high resistant to heating and chemical processing during production. Furthermore, the carrier glass prevents the ultra-thin glass from coming into direct contact with processing equipment to prevent defects such as scratches, and can be easily delaminated after processing.

A sample of the laminated substrate will be exhibited at AGC’s booth at the Society for Information Display (SID) exhibition in Boston, U.S.A. from June 4..jpg)

Production processes using ultra-thin laminated glass substrate

AGC strives to provide optimal solutions to customers by pursuing the possibilities of glass through its advanced float glass manufacturing technology, as well as by establishing the process technology to expand new applications for glass.

About the AGC Group

The AGC Group, with Tokyo-based Asahi Glass Co., Ltd. at its core, is a world-leading supplier of flat, automotive and display glass, chemicals and other high-tech materials and components.

Drawing on more than a century of technical innovation, the AGC Group has developed world-class expertise in fields including glass, fluorine chemistry and ceramics technologies. The group employs some 50,000 people worldwide and generates annual sales of more than 15 billion USD through business in about 30 countries. For more information, please visit www.agc-group.com/en.

Media Contact

Toshihiro Ueda, General Manager, Corporate Communications & Investor Relations

AGC Asahi Glass Co., Ltd.

(Contact: Satoshi Yoshida; Tel: +81-3-3218-5603; E-mail: info-pr@agc.co.jp)

Add new comment