Date: 21 May 2013

The product, which significantly simplifies the process of bonding cover glass directly to display devices, will greatly contribute to the proliferation of more vivid and clear displays.Optical bonding optimizes the refractive index of resin to minimize the loss of light for enhanced visibility.

Samples of AGC’s self-adhesive glass for optical bonding will be displayed at Society for Information Display (SID) in Vancouver from May 20.

As a technology to improve the display quality of mobile devices and others, bonding cover glass directly to the display is on the verge of gaining wide popularity. Direct bonding realizes high contrast images by minimizing reflection while enhancing image sharpness, but it also has the drawbacks of requiring high-temperature, high-pressure processing and the curing process of the resin. In addition, the quality is particularly prone to be ununiform in midsize and large liquid crystal displays (LCDs) when direct bonding is used.

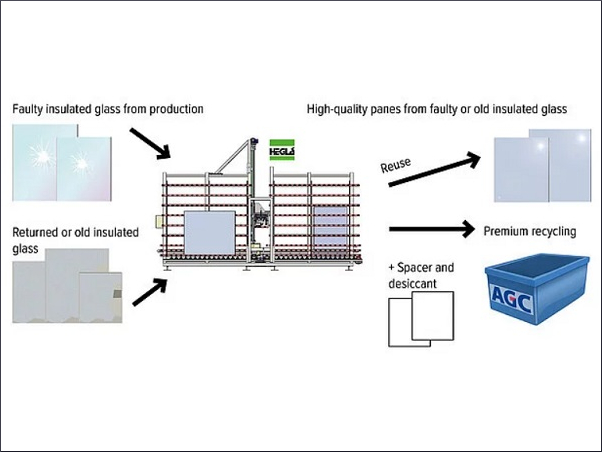

In response, AGC’s new cover glass has enabled the direct bonding of cover glass and display devices without creating a void by using a newly-designed resin for bonding that is set on the bonding surface. Any air bubbles that form during the bonding process are automatically absorbed in the resin. Bonding using this product does not require complex processing, such as high-temperature, high-pressure treatment, so processing can be accomplished with a much simpler methodology. Also, the productivity is largely superior to conventional processing methods, and the process is expected to be applied to even larger displays.

The new product also is suitable for IPS-mode LCDs, of which image quality is prone to be ununiform due to the pressure created when the cover glass is bonded to the LCDs. IPS stands for In-Plane Switching, a type of liquid crystal display that is increasingly being used in mobile handsets. Going forward, AGC’s new cover glass is expected to be used in these and many other types of LCDs..jpg)

Looking ahead, AGC expects to develop new products and technologies for increasingly sophisticated displays by integrating diverse glass and chemical technologies for glass materials design and processing, organic materials and coating. About the AGC Group The AGC Group, with Tokyo-based Asahi Glass Co., Ltd. at its core, is a world-leading supplier of flat, automotive and display glass, chemicals and other high-tech materials and components. Drawing on more than a century of technical innovation, the AGC Group has developed world-class expertise in fields including glass, fluorine chemistry and ceramics technologies. The group employs some 50,000 people worldwide and generates annual sales of more than 11 billion USD through business in about 30 countries.

For more information, please visit www.agc-group.com/en.

Media Contact Toshihiro Ueda, General Manager, Corporate Communications & Investor Relations Asahi Glass Co., Ltd. (Contact: Yasuo Sugiyama; Tel: +81-3-3218-5603; E-mail: info-pr@agc.com)

< Reference >.jpg)

Add new comment