Sometimes it may be this easy, but increasingly often this is far from the truth. As forehearth complexity increases to give better results, their operation also becomes more complicated, requiring more time and/or specialist knowledge to achieve the required results. However, there are some additional systems specifically designed to improve and/or simplify forehearth operation.

Part 1 of this article looks at some of these.

The forehearth CONTI-DRAIN®

The increased occurrence of zircon cord in the production is almost certainly not a forehearth problem as such. Most informed opinions agree that the main source is the melter, where increasing amounts of fused cast AZS material are being used in the superstructure. Nevertheless, after several years of trying to solve the problem in the furnace, the introduction of the forehearth CONTI-DRAIN® system in 1999 finally presented a practical method of reducing or eliminating zircon cord.

The contaminated glass, almost always found at the very bottom of the glass bath, can be removed by a small drain unit used in combination with a specially developed drainage channel block. If the drainage block is correctly dimensioned the removal can also be effective even if the contaminated glass is not in the centre of the channel.

The original system utilises a counter electrode in contact with the glass bath. It is well known that molybdenum electrodes can react with some highly oxidised glasses to produce blister and dark grey deposits in the glass.

A further system development has now been released which does not require an electrode to be in contact with the glass bath. The basic principle used is the same as for the standard system, and so the same excellent results are obtained. But, as there is no electrode in contact with the glass, there is no risk of glass quality degradation. This new system is called CDNE.

Since the original installation was made more than 120 forehearth CONTI-DRAIN® systems have been supplied – ample proof of their effectiveness.

The equalising section electrical boosting system

The use of electrodes in the equalising section of a gas heated forehearth to improve the thermal homogeneity has a long history, with the first such systems being installed towards the end of the 1960s. However, it is only in recent years that their true potential has been universally accepted.

If correctly designed and operated, a small electrical heating system utilising immersed electrodes can provide two clear advantages.

The system can be used to selectively heat “difficult” areas of the glass bath, such as the lower corners and the bottom, which may have a tendency to become too cold, and which are, at best, extremely difficult to heat using the normal gas heating. In addition, it is also possible to heat one side more than the other to eliminate a side-to-side difference. Experience has shown that such systems are ideal for improving thermal homogeneity.

The second advantage might be considered equally important. The effect of a change in the power input by part of the system is seen almost immediately. If a change results in a worsening of the thermal homogeneity it can be quickly reversed, or if it was too little a further change can be made in quick succession. This quick reaction is very useful if an automatic control system is being used, and it also means that the hard-pressed production department can make adjustments and see the results quickly – a very important advantage.

The automatic oxygen trim system

Until now automatic air/gas ratio control in forehearths by measurement of the oxygen content of the waste gases has been a relatively expensive exercise with questionable long term reliability. A newly developed and patented system includes two important features that address these issues.

The unique delign of the patented OMT system utilises a small zircon oxide sensor to monitor the oxygen content of the waste gases from the combustion directly in each zone on the forehearth itself, rather than at a separate burner, as was the case with previous systems. This arrangement greatly simplifies the equipment required.

A simple method for adjusting the air/gas ratio is also necessary if the oxygen trim is to be automated, and in the past this has always been done by varying the amount of gas provided for a given amount of air. This method works well at higher gas flow rates, but the necessary fine adjustment may be difficult at the low gas flow rates that occur when the zone is at low fire unless very expensive, high precision hardware is used. The OMT system offers a better and much simpler solution.

Instead of varying the gas supplied for a particular amount of air, the OMT system varies the air supplied for a particular amount of gas. As the air quantity used is approximately ten times greater than that of gas (in the case of natural gas) it is much easier to make small adjustments.

Modern high pressure forehearth gas heating systems such as the SORG VMC system claim to maintain the air/gas ratio at a constant level across the complete operating range – typically 5 - 60 mbar at the burners. If this really is the case, why is an automatic oxygen trim system necessary?

Whilst it is obvious that many forehearths will not require such a system, there are some situations when its use is a definite advantage.

One obvious example is in the colourant feeding zone of colouring forehearths, where very specific atmospheric conditions may be needed to attain certain colours. It may also be advantageous to use such a system when heavily reduced glasses are being handled. Although the basic gas heating system, once correctly set up, will normally be capable of retaining the setting, there may be a tendency amongst operating personnel to adjust the air/gas ratio setting if a zone is not reacting as expected. In most cases the source of the problem lies elsewhere, but a tweak of the ratio is often the first attempt to cure the problem. This is unnecessary if automatic air/gas ratio control is in use.

Part 2 – control systems

Increasing complexity and the integration of additional systems can often be well handled by an improved control system

Almost all forehearths are provided with automatic temperature control, which suggests that operating personnel have little to do except set the required temperatures and let the automatic control system do the job. However, conventional forehearth control often requires considerable operator input before acceptable conditions are obtained.

The real aim of control systems

This appears to be a simple question but the answer is really quite complex. Ideally the operator should only have to enter the required temperature at the end of the forehearth channel and the automatic control system should attend to everything else. This leads to four major aims in addition to the obvious job of maintaining constant temperatures:

- selection of the correct set points for the rear and middle zones

- achievement of an acceptable level of thermal homogeneity at the end of the forehearth channel

- maintenance of this level of thermal homogeneity

- maintenance of a high level of stability on all temperatures

Temperature stability is of the utmost importance as it normally influences gob weight directly. Unfortunately, changes made to achieve any of the first 3 requirements tend to produce at least temporary instability, and any practical solution must be a compromise between improving conditions and maintaining stability

Conventional control systems

Conventional forehearth control systems are remarkably simple, the output of a single temperature sensor in each control zone is taken to a controller, usually a single loop PI (proportional/integral) controller or a software controller embedded in a SCADA system. There is no direct connectin between the control loops of the various zones, nor to the temperature matrix measurement located at the end of the forehearth equalising section.

Operator input is needed to determine set points for each of the control zones, and as the relationship between these values may signifycantly influence the thermal homogeneity of the glass at the end of the channel, his ability and experience can be an important operational factor.

Improved PI operation

PI control is always a compromise between fast reaction to changes and general stability, but modern PI controllers provide more than the standard proportional band (P) and integral time (I) parameters.

A simple improvement involves a second set of PI control parameters. In normal operation the control system should avoid large changes in controller output, and parameters are chosen accordingly. However, if the actual temperature moves too far from the set point the control parameters can be modified in order to return quickly to the correct temperature value. This is done by monitoring the difference between set point and actual temperature and automatically switching to a second, faster set of control parameters, if the difference exceeds a preset value.

Most electronic controllers also offer a set point trim function that can be used to modify the set point on the basis of an external signal. With forehearth control the temperature information from the 9-point matrix measurement at the front of the forehearth can be used to modify the rear and middle zone set points.

Control of heating/cooling

Rear and middle forehearth zones often have both cooling and heating systems, and here the methods used to control the two systems are important.

Some systems utilise an arrangement where either the heating system or the cooling system is used to control the zone temperature at any one time, depending on the operating situation. In each case the other system is at zero output. This has a number of disadvantages, including the arrangement of the changeover point from heating to cooling or vice versa. However, the largest potential disadvantage derives from the fact that in modern forehearths the central glass stream can be cooled whilst at the same time the glass at the channel edges is being heated. This type of control cannot deal with this arrangement.

To improve the situation control loops for the heating or the cooling system can be provided. The cooling system is used to control the central temperature and the heating for the side temperatures. Even if there is no separate left/right heating, this arrangement increases the cost and complexity of the control syste and requires the operator to select two (or possibly three) set points for one forehearth zone.

A second solution uses the heating system to controle zone temperature. The cooling is adjusted in steps, but only to keep the output of the heating controller within acceptable limits. This results in good continuous temperature control requiring only occasional small adjustments to the cooling system.

Advanced control functions

It is well known that in coloured glasses the rear and middle forehearth zone temperatures directly influence the bottom and centre temperatures at the front of the channel. This can form the basis of an advanced control strategy in which the rear and middle zone set points are automatically modified to improve the thermal homogeneity of the glass bath at the end of the channel. If the forehearth zones are provided with split left/right heating, this control system can be extended to give left/right correction.

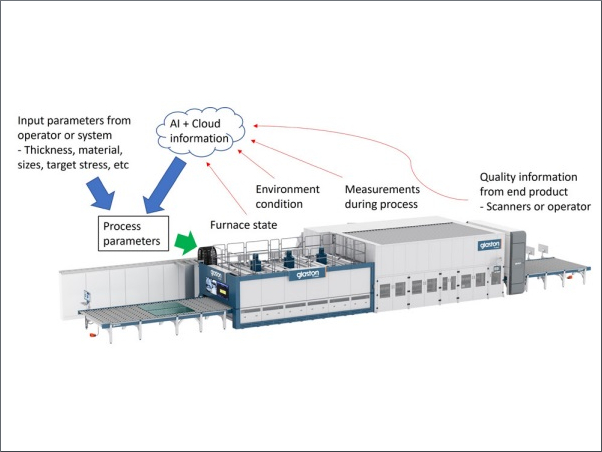

Model-based control systems

In theory the best possible control should be provided by a model-based predictive control system, based on standard forehearth models. They analyse forehearth operating data over a time to “understand” how the particular forehearth runs. They then use this knowledge to analyse forehearth operation in real time and make appropriate adjustments to obtain the required results.

The earliest such systems were introduced about 15 years ago, and significant increases in available computer power together with much improved modelling technology should mean that it is now possible to produce a very intelligent and competent system. Yet for various reasons only relatively few are in actual use.

For instance certain operational factors on some forehearths cannot be measured and are therefore not part of a mathematical model. These include the movement of air within the factory, which can affect some cooling systems, the effect of the opening of peepholes, and the effect of glass level changes on thermocouple readings.

Another reason is the total system cost that must be set against potential gains. It must be very difficult to prove an increase in productivity due to a new control system on a container line already operating a percentage pack in excess of 90 %.

Finally, there is the question of the reliability of such a system. It may be difficult for an observer to understand what the system is actually doing at a particular moment, and this may lead to a loss of confidence.

It is surprising that even the most demanding production can still be run on conventional controlled forehearths and this fact alone provides important information about the capabilities required in an advanced control system. During and immediately after job changes there is a clear need for an improved control system to select the correct set points for rear and middle zones and to speed up stabilisation.

Once stable conditions have been obtained it is usually better to leave the forehearth alone and concentrate on stability rather than optimisation.

In coloured glasses it is much easier to improve thermal homogeneity by using an electrical boosting system in the equalising section rather than try to use an “intelligent” control system that optimises operation by making changes over a long time, thereby creating instability.

Richard Sims, Nikolaus Sorg GmbH & Co KG