Authors: Rena Giesecke & Benjamin Dillenburger

Source: Glass Structures & Engineering, volume 7, (2022)

DOI: https://doi.org/10.1007/s40940-022-00176-y

Abstract

The presented research investigates a digital fabrication method for custom glass building elements based on three-dimensionally (3D) printed molds. Custom glass parts with specific geometries usually require several steps of manufacturing, highly specialized craft, or machinery. Computer Numerical Control milled steel molds are only suitable for large lot sizes due to their high cost and limited geometric freedom. Lost-wax casting requires several steps of manufacturing and post-processing. This paper investigates an accessible, low-cost process for shaping glass artifacts using 3D-printed molds to close the gap between mass-produced and custom-crafted glass elements. Previous research has demonstrated the potential of using binder jetting with inorganic binders for glass casting. This paper investigates a range of traditional manufacturing methods besides glass casting that can be combined with 3D-printed molds, including foundry and kiln casting, blow molding, and slumping.

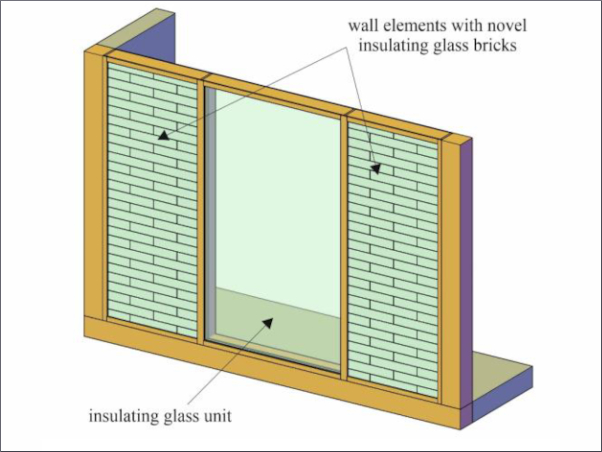

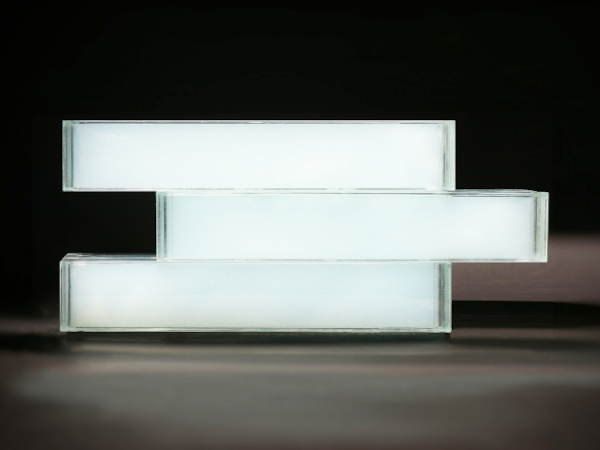

The aim is to extend the manufacturing possibilities and provide a range of approaches for three-dimensional glass. The goal is to simplify the process from design to production of three-dimensional solid, hollow, or doubly curved sheet glass elements with high precision. This paper presents investigations of binder jetting techniques and material considerations, their heat resistance, compatibility with different glass- making processes, and coatings for mold treatment. Furthermore, the precision of the resulting glass parts is evaluated, and design guidelines for glass typologies are defined. Glass bricks or sheets for facades with geometric features enabled by the presented fabrication method could allow for novel optical, structural, or decorative properties in building elements.

1 Introduction

1.1 Background

Glass played an essential role in the history of culture and architecture and was first discovered by humans in the Bronze Age in the middle of the third millennium BCE in Mesopotamia (Wight 2011). In the Roman period, household objects were made using frit casting, which involved fusing small glass granules under heat inside a mold. Since then, glass molding has played an essential role in glassmaking. In the 1st century BCE, the Phoenicians invented glass blowing to manufacture hollow artifacts such as vessels and bottles. The Romans were the first to use small, partially transparent, cast glass pieces in buildings in 100 CE (McGrath and Frost 1937). From the 18th century, cylinder blown sheet glass or crown glass was used to produce windowpanes. Swiss architect Gustave Falconnier modified the traditional bottle blow molding process by utilizing steel molds to manufacture hollow glass bricks for architectural purposes (Jeandrevin 2018).

In 1887, industrial blow molding enabled the mass production of vessels and household objects. In 1959, the invention of the float glass process enabled the mass production of float glass as a standardized product for construction (Pilkington 1969). Today, mass-produced glass parts are covering a significant market worldwide (Statista 2021), while custom crafted glass is a declining industry (Guardian 2021). Mass-produced molds for glass components are typically made of stainless steel or graphite, whereas for customized glass objects molds are typically either made using sand pressing or plaster-silica molds. The molding method’s choice depends on the required precision, geometric, and production number of parts and the molding material is specific to the glass processing method applied. For the sand pressing method, a wooden pattern is pressed into a sand-clay-bentonite mix before casting for the sand pattern molding process.

For the lost-wax technique, a wax or plastic positive is manually sculpted, or CNC-milled, followed by a plaster-silica mixture cast around the positive (Feinberg 1983). However, the technique is time-consuming and laborious, and the glass surface in contact with the mold results in a rough surface that requires post-processing for a transparent result which is likely to affect the precision of the glass object. While CNC-milled steel molds are highly beneficial for large-scale applications and high-precision elements with high lot sizes (Oikonomopoulou et al. 2018), they are too costly for small production numbers and partially limited in geometric complexity. Although some multi-component steel molds can allow manufacturing complex parts, they cannot produce undercuts in complex parts because the mold could not be removed.

1.2 State of the art

Recent developments employ 3D printing of plastic to produce the positive for the lost-wax technique (Dudly 2019). After melting the plastic, the ceramic mold remains, and glass is cast into the cavity from a container placed above it. This process can result in precise parts but requires several steps and post-processing of the rough glass surface to achieve transparent results. Several mold-free 3D printing methods for glass have been developed in the last years, including micro-scale 3D printing processes such as printing transparent fused silica glass (Kotz et al. 2017). The Mediated Matter Group at the Massachusetts Institute of Technology (MIT) has developed an extrusion-based process for printing optically transparent glass objects of up to 25 × 25 × 30 cm dimension within a heated chamber (Klein et al. 2015). However, direct glass 3D printing is limited in scale and geometry and requires highly specialized equipment and expertise.

The Glass and Transparency Group at TU Delft is researching the use of structural and recycled cast glass (Bristogianni et al. 2018) and has presented the first proof of concept for using 3D-printed sand molds as part of a review of different glass molding methods (Oikonomopoulou et al. 2020). The latter research demonstrates the feasibility of using 3D-printed sand molds and inorganic binders for kiln glass casting and the use of coatings to achieve transparent finishing surfaces for kiln-cast glass parts. A Swedish research group has also investigated the use of 3D-printed sand molds for glass casting. In this context, the group has made findings concerning coatings for foundry glass casting (Lundstedt et al. 2022). Furthermore, 3D-printed sand molds have demonstrated their potential for applications in the field of construction for complex structures made of concrete and metal. Examples include 3D-printed sand molds for concrete building elements (Jipa et al. 2017) and for cast metal nodes developed by Arup (Galjaard et al. 2015).

3D-printed molds for concrete have the potential to produce high-resolution complex geometries that cannot be fabricated with direct 3D printing methods and 3D-printed sand molding for cast metal have significant cost advantages over directly 3D-printed parts. In general, 3D-printed sand molds are advantageous for producing complex parts with small lot sizes and high precision requirements. For glass, 3D-printed sand molds have unique potential for producing intricate geometries with undercuts that cannot be produced with multi-component steel mold due to the enclosure of the glass parts or steel mold or in cases where traces of segmentation seams are undesired. In such cases, they can perform as a disposable mold that is removed through breakage. Additionally, 3D-printed sand molds are highly beneficial for single parts, prototypes, or small lot sizes due to the significantly lower cost than steel molds. Compared to other disposable molding techniques such as the lost-wax technique, 3D-printed sand molds have several advantages as being less labor-intensive, highly precise, and without the requirement of post-processing of the glass part.

1.3 Approach

The objectives of this research are:

- To define new ways of manufacturing for custom glass parts based on Additive Manufacturing (AM).

- To investigate how 3D-printed sand molds are compatible with different glass processing methods.

This research extends existing research by investigating a wide range of different glassmaking techniques combined with 3D-printed sand molds. The goal is to enhance traditional techniques with the latest AM methods and provide a range of strategies for custom glass parts. More specifically, the research examines whether glass kiln and foundry casting, blow molding, and slumping are compatible with 3DPM to provide an accessible and precise digital fabrication method for custom three-dimensional glass parts. The proposed method reduces manual labor and high cost of crafting methods and overcomes the scale limitations of direct glass 3D printing methods. Furthermore, the paper expands on the related requirements for each of these processes, the precision of the results produced, and presents design guidelines for different typologies. It is crucial to choose the fabrication method for the intended geometric features with the limitations specific to each manufacturing method. Glass casting is suitable for solid freeform objects, blow molding for hollow freeform objects, and slumping for doubly curved sheet glass.

2 Methods and materials

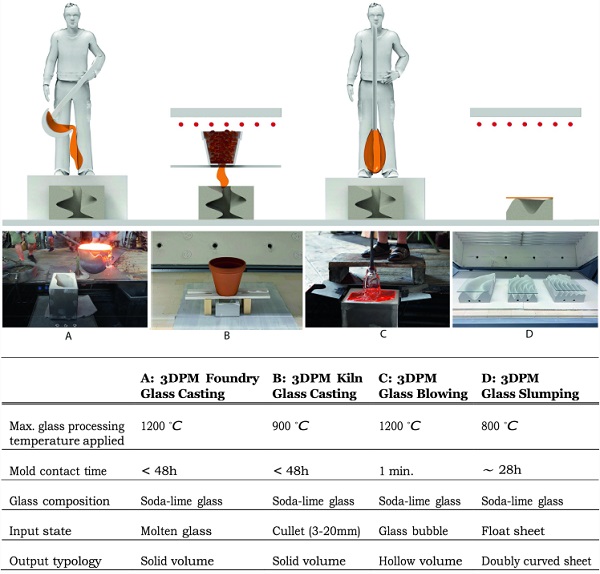

To investigate the compatibility of 3D-printed sand molds with different glass processing methods, four different methods, namely foundry, and kiln glass casting, blow molding, and slumping, are tested. Table 1 provides an overview of the investigated glass processing methods, including processing temperatures, mold contact times, glass type, input stage, and the output typology. In the following, the term typology is used for the different types of glass parts such as volumetric solid parts, volumetric hollow parts and doubly curved panes. The main parameters that will be assessed in this research for each of the four glass processing methods related to glass quality and to the fabrication process are:

Table 1 Overview of Three-dimensionally Printed Molds (3DPM) glass manufacturing methods and setups - Full size table

Glass quality-related assessment parameters:

- Surface finishing quality.

- Level of precision.

- Geometric freedom and limitations. Fabrication process-related assessment parameters:

- Possibility to reuse the mold.

- Cost and time for mold production.

The surface finishing quality is verified based the optical transparency of parts and smoothness of the resulting surface in relation to the different coatings tested. The possibility to reuse the mold is verified based on repetitive use of the mold. The level of precision is inspected using 3D scanning of the molds and glass parts. The geometric limitations are examined through iterative testing and digital comparison using 3D scanning. The cost and time for mold production is inspected based times and costs provided by the service provider and by measuring processing times during experiments.

All experiments are executed with sand molds printed by ExOne using binder jetting and inorganic sodium silicate binder (ExOne 2022). All produced molds are printed as one single piece. Coating materials tested to achieve optically transparent surface properties include water-based and alcohol-based coatings. An overview of the specific coating products used is provided in Sect. 3.2.1 in Table 4. Before executing experiments, molds are dried at 200 °C temperature to avoid failure through humidity captured in the molds. Soda- lime glass is used for all experiments. The kilning experiments are executed in a Nabertherm GF600 glass kiln (Nabertherm 2021). To investigate the precision of molds and glass parts, they are 3D scanned using the GOM ATOS CORE 300 scanner with a scanning precision of 10–20 µm. Prior to scanning,glass samples are sprayed with scanning spray named AESUB blue (3D Ware 2021) to avoid subsurface scattering effects in the scanned data. The data comparison is conducted with GOM Inspect software.

3 Experimental work

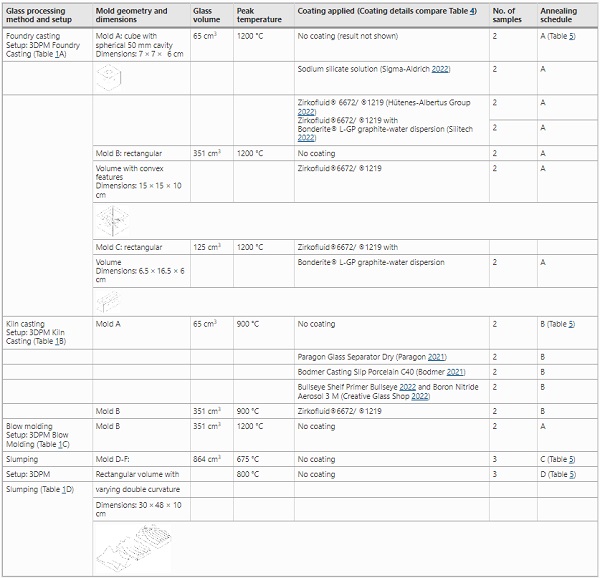

Table 2 provides an overview of all experiments conducted in this research, including the glass processing method and setup used, the mold geometry, glass volume, coating products applied, number of samples tested, and the annealing or kilning schedule. A different processing viscosity and temperature are required for each glass processing method, resulting in different requirements for each molding process.

Table 2 Overview of the experiments conducted in this research - Full size table

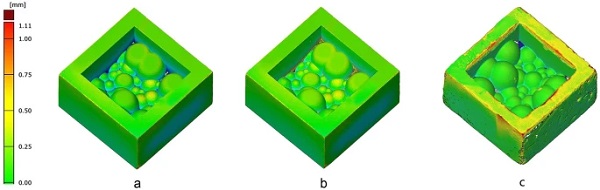

3.1 Production of molds

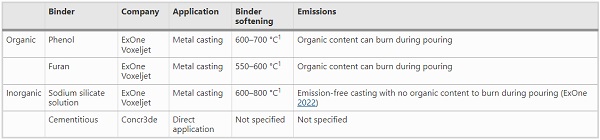

This section provides an overview of binder jetting systems currently available on the market and examines their viability for glass casting. They are categorized by binder type, company, casting application, temperature resistance, and emissions under heat (Table 3). Binder jetting of silica sand enables the fabrication of 3D-printed parts with high geometric complexity, high accuracy (Voxeljet 2022). In an automated process, loose silica sand of 130 µm grain size is distributed and locally bound by printing a 2D pattern of binder layer by layer. The advantage of binder jetting methods is that increased geometric complexity does not add additional time to fabricate the mold. The 3D scan of a solid 15 × 15 × 10 cm print (Fig. 1) identifies the high precision of less than 0.25mm deviation from the digital 3D model can be achieved (compare Fig. 8 in Sect. 4.2). The use of organic binders for binder jetting of sand molds is established for the industrial casting of freeform metal parts. However, phenol and furan can emit fumes during casting when organic contents burn (Showman and Scheller 2015).

Thus, organic binders are excluded from the following experiments as they require specialized ventilation systems for kilns and staff protection in the research facility and foundry. Inorganic binder jetting solutions, which are currently new on the market, provide a promising alternative to organic binder jetting systems as they are suitable for high-temperature casting and allow for emission-free casting with no organic content burning during pouring (ExOne 2022). In the case of inorganic binders, the binder structures soften at temperatures between 550 and 700 °C. With furanic binders, softening starts between 550 and 675 °C. With phenolic binders, softening tends to start slightly higher. However, the softening process can be delayed by using special sands, such as Cerabeads.Footnote1 As glass foundry casting requires temperatures of approximately 1200 °C and kiln casting of 900 °C, molds are exposed to significantly higher temperatures. In the realm of inorganic binder jetting systems, water glass, also called sodium silicate, binder, and inorganic cementitious binder, are currently on the market and being tested.

Initial tests of cementitious binder from Concr3de (ConCr3de 2022) result in boiling of the glass during casting for unspecified reasons, while sodium silicate binder resists the casting and annealing process without structural failure of the mold or gas developments. While small print volumes can be printed without any defects, solid volumes of 45 × 45 × 25 cm in size demonstrate stress cracks that result from the hardening process after printing. Voids are integrated into the geometry to mitigate this issue and reduce the print volume. Nevertheless, stress cracks still occur. The racy of ± 0,4 %, and 280 µm standard layer cracking process of larger parts can be successfully delayed by using special sands such as Cerabeads so that 45 × 25 cm parts can be printed successfully.

Table 3 Sand binder jetting systems - Full size table

3.2 3DPM glass casting

This section investigates the feasibility of using 3DPM molds for foundry and kiln glass casting.

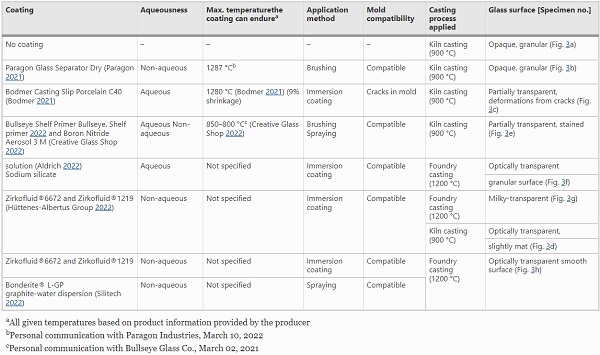

3.2.1 Mold coating

To produce optically transparent glass casts with smooth surfaces and allow easy mold removal, coating of the mold is required. It is not recommended to post-process the glass for better surface quality as sanding or cutting is highly labor-intensive and can weaken the part structurally. Requirements of coatings for glass casting are:

- Temperature resistance: Resistance to temperatures of 1200 °C (long time contact) for casting, 800 °C (long time contact) for slumping, and 1200 °C (short term contact) for blow molding.

- Non-aqueousness: Required to avoid dissolving the binder material due to water content.

- Coating application: Allow for even coating thickness that preserves the mold details through spraying, brushing, or immersion coating.

- Process compatibility: Compatibility of the 3D-printed mold with the kiln and foundry casting process.

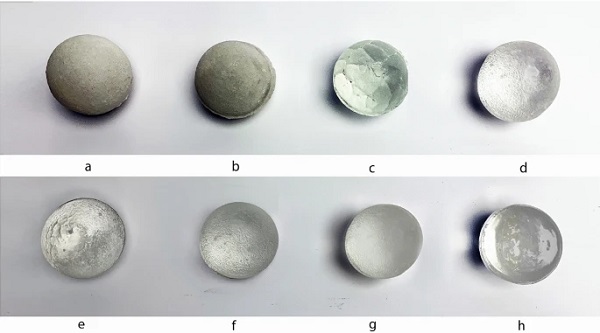

Table 4 provides an overview of all coatings tested for kiln and foundry glass casting, their indicated temperature resistance, application method, mold and process compatibility, and resulting glass surface properties. Coatings are tested either with kiln or foundry casting, based on their indicated temperature resistance. Initial kiln casting tests without mold coating (Fig. 3a) and with powder-based release agents (Fig. 3b) result in opaque surfaces of glass objects. In the first phase of the coating research, water-based ceramic and concrete coatings are examined for compatibility with the inorganically bound sand mold. However, water-based coatings dissolve the print or cause surface cracking of the mold resulting in marks in the cast glass (Fig. 3c).

In the next step, common off-the-shelf hobbyist coating materials were tested for kiln casting, including powder-based Paragon Glass Separator Dry (Fig. 3b), Bodmer Casting Slip Porcelain C40 (Fig. 3c) Bullseye Shelf Primer and Boron Nitride Aerosol 3M spray (applied as a second layer) (Fig. 3d). The powder- based Paragon Glass Separator Dry release agent resulted in opaque casts with no coating or release agent applied (Fig. 3a). Bullseye Shelf Primer leaves opaque stains on the surface of the glass (Fig. 3d). Due to the lack of transparency in initial results, sodium silicate coating and non-aqueous alcohol-based high-temperature coatings Zirkofluid®6672 and Zirkofluid®1219 are tested for kiln casting (Fig. 3f) and for foundry casting (Fig. 3g). In contrast to aqueous coatings, alcohol-based coatings have the advantage of not dissolving the sodium silicate binder.

Zirkofluid®6672 and Zirkofluid®1219, as well as the sodium silicate solution, are applied in an immersion coating process (Fig. 2) to achieve a coating result with even thickness. Sodium silicate coating results in optically transparent, precise glass parts, but the grainy surface of the sand mold is transferred to the cast (Fig. 3e). Zirkofluid®6672 and Zirkofluid®1219 result in optically transparent glass with smooth surface properties, for kiln casting at 900 °C (Fig. 3d). Foundry casting with Zirkofluid® coating results in transparent, however slightly milky surface properties (Fig. 3g). Before application, the coating is diluted with 25 percent Isopropanol to provide a suitable viscosity for the immersion coating process. The process consists of pouring the coating into the mold and removing it after 13 seconds to achieve a target thickness of approximately 50µm. The resulting wet thickness of the coating is measured using a thickness gauge and can be adjusted as desired. The alcohol content must evaporate or be burned before initiating the casting process. After various tests, it is found that this coating thickness results in the best surface finish of the glass while still preserving the geometric properties of the mold.

Table 4 Mold coatings tested: Resulting specimens in Fig. 3 - Full size table

To address the issue of the milky surface of foundry cast glass parts, an additional layer of graphite-water dispersion named Bonderite® LGP (Silitech 2022) is tested and sprayed on top of the Zirkofluid® coating resulting in smooth, optically transparent glass parts (Figs. 3h and 5e, d). Graphite lubricants are commonly used for foundry casting of metal at high temperatures and are advantageous because they have excellent separating properties (Fuchs 2022). According to the producer, it was investigated with thermogravimetric analysis that Bonderite® graphite lubricant used starts to burn away at around 600 °C.Footnote2 Although the casting temperature is significantly higher at 1200 °C, surface properties of the cast part are entirely optically transparent (Fig. 4). It can be assumed that the temperature at the contact surface of the mold is significantly lower than the casting temperature and stays below the 600 °C temperature limit of the product. Additional factors that impact the performance of the graphite spray are the cooling speed of the glass during casting, the oxygen feed from the surrounding environment and the removal of the CO2 through the openings and pores of the mold. Further investigations of these parameters are required.

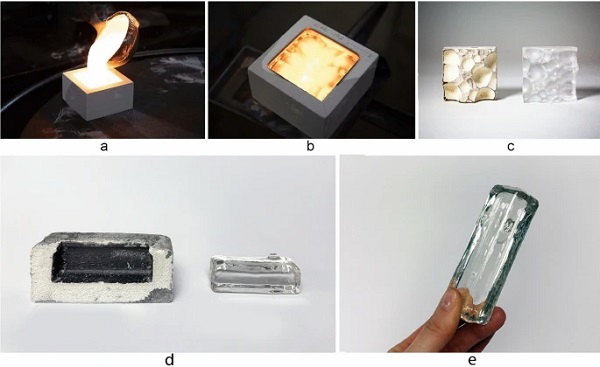

3.2.2 Foundry glass casting

For the foundry glass casting process, also called hot-pouring, molten glass is poured into the mold by the artisan using a casting ladle. Figure 4 shows the resulting transparent kiln cast glass part removed from the 3D-printed mold after annealing. The casting temperatures vary between 1100 and 1400 °C for soda-lime glass depending on the viscosity required for the glass to flow and fill the mold. Before casting, the mold should be thoroughly dried with no humidity enclosed in the pores as humidity can cause air bubbles during the casting process and in the cast glass. The glass is analysis that Bonderite® graphite lubricant used then cast into the mold using a ladle (Table 1A). After the glass is cast into the mold, it is placed in the kiln for the annealing process required to release internal stresses from the glass (Fig. 5b).

The annealing times can vary significantly from several hours for small parts up to a year for large parts, depending on the glass volume and geometry (Oikonomopoulou et al. 2018). Table 5 (annealing schedule A), shows the specific annealing schedule applied for foundry casting. Zirkofluid®6672, Zirkofluid®1219, and sodium silicate coating do not cause emissions or fumes in the foundry casting process. Molds coated with sodium silicate result in optically transparent results with a grainy surface structure from the sand (Fig. 3f). Molds coated with Zirkofluid®6672 and Zirkofluid®1219 produce transparent but milky surface properties (Fig. 3g). Figure 5c shows the result of an uncoated mold (left) and a Zirkofluid coated mold (right).

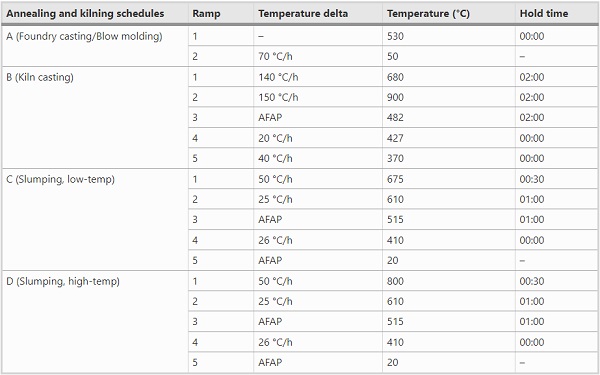

Table 5 Annealing and kilning schedules - Full size table

To improve the surface property of the glass further, an additional coating with Bonderite® L-GP graphite-water dispersion is applied (Fig. 5d) and produces fully transparent, smooth surface properties (Fig. 5e).

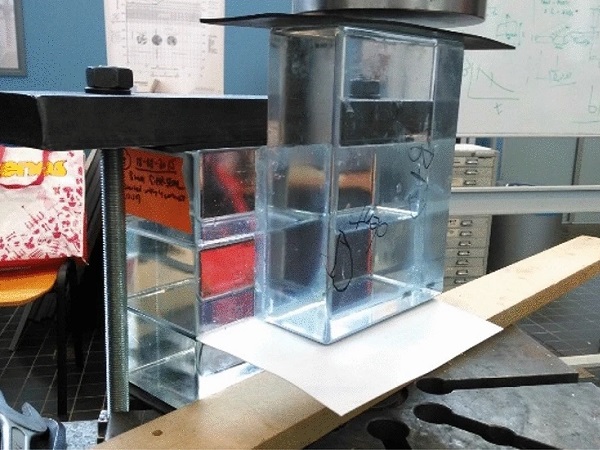

3.2.3 Kiln glass casting

For the glass casting process in the kiln, glass nuggets are placed inside a ceramic container and melted into a mold placed below at 900 °C peak temperature (Fig. 5c). Table 5 (annealing schedule B), shows the specific annealing schedule applied for foundry casting. If no coating is applied to the sand mold, the sand grains are attached to the surface of the glass cast (Fig. 3a). Paragon Glass Separator also produces opaque surface properties (Fig. 3b), and Bodmer Slip Casting Porcelain results in cracks in the mold due to shrinkage of the material, which leave traces in the mold (Fig. 3c). Zirkofluid®6672, Zirkofluid®1219 are suitable coatings for the kiln casting process and result in transparent, however slightly milky, surface properties (Fig. 3d).

3.3 3DPM glass blowing

For the glass blowing process, the artisan takes a batch of molten glass from the foundry furnace, shapes it into a glass sphere, and inflates it by blowing air through a pipe into the glass batch (Fig. 6a). The inflated glass balloon is placed within the mold and further inflated until it touches the walls of the mold (Fig. 6b). The blown glass can be immediately removed and placed in the kiln for the annealing process for geometries without undercuts. Traditionally wooden molds are used for geometries with under- cuts, but 3D-printed sand molds are also suitable as they can endure the annealing process in the kiln. Table 5 (annealing schedule A), shows the specific annealing schedule applied for blown glass parts in the foundry. Depending on the volume of the glass part, the wall thickness can vary between 3 and 20mm with slightly increased wall thicknesses in the corners.

3DPM blown glass has optically transparent properties and is an efficient technique for the creation of hollow and lightweight glass parts (Fig. 6c). For optically transparent results, no coating is required. This is most likely related to less than one minute’s short contact time with the mold. Minor traces of sand grains can occur on the mold-contact side of the glass at higher temperatures. However, in cases where perfect smoothness is required, minor traces can be eliminated using Zirkofluid® coating. The blow molding tests presented in this paper were executed without coating, but further tests have experimentally proven the suitability of Zirkofluid® coating for blow molding.

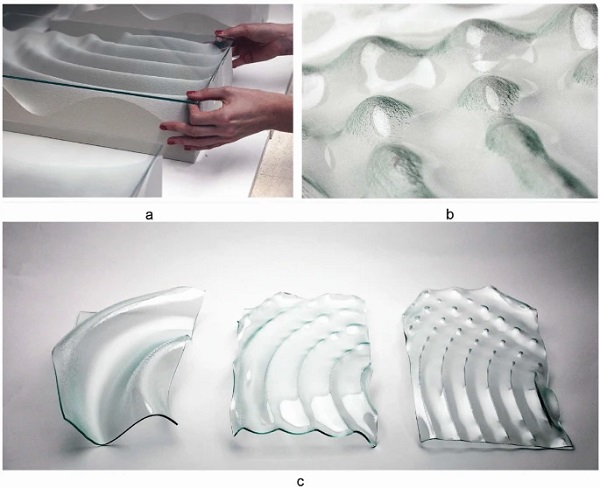

3.4 3DPM glass slumping

The slumping process enables the shaping of a flat float glass pane into a doubly curved glass surface. A flat glass sheet is placed on top of the mold in the kiln (Fig. 7a) and formed with gravity onto the 3D-printed sand mold. Figure 7c shows the resulting curvature in 30x48cm sized glass panes and 7b the double curvature from close. In this research, two different peak temperatures are tested to assess the limitations of slumped doubly curved float glass. Table 5 shows the two annealing schedules applied for slumping at 675 °C (annealing schedule C) and at 800 °C (annealing schedule D). For optically transparent results, no coating is required for this process because the slumped glass is processed under comparatively low temperatures of 675–800 °C with lower glass viscosity than in the casting process. Thus, the sand does not fuse with the glass pane. Minor textures resulting from the grainy sand can potentially occur on the mold-contact side of the glass pane at higher temperatures.

However, if such minor traces are undesired and perfect smoothness is required, they could be fully eliminated by using Zirkofluid® coating. The slumping tests presented in this paper were executed without coating, but further tests have experimentally proven the suitability of Zirkofluid® coating for slumping. Mold geometries with different curvature intensities were tested to investigate the geometric limitations of doubly curved glass. Results and process parameters will be further examined in Sect. 4.3. As mold reuse is desirable, the stability of the mold over several repetitions was tested. While molds remain fully stable in the first iteration of the process, they demonstrate cracks and breakage on the tips of the geometry in the second and broken corners in the third iteration of the process. The breakage is primarily caused by mechanical force applied to the mold and the softening of the binder.

4 Design-related investigations

4.1 Typologies

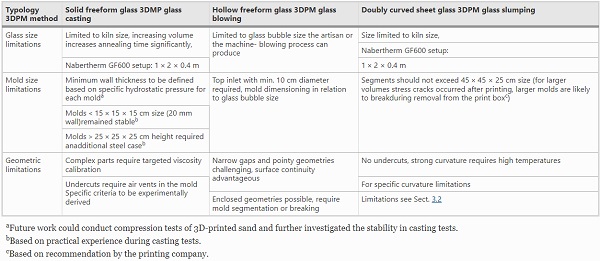

This paragraph summarizes the main aspects to consider when designing 3DP molds for glass manufacturing. The method should be chosen in relation to the desired design features and typology. Glass casting is suitable for solid objects, blow molding for hollow objects, and slumping for doubly curved sheet glass. Table 6 provides an overview of the typologies that can be produced with the presented methods as well as information on the design aspects to consider in terms of size limitations, geometric limitations, and mold geometry and dimensions. The limitations and dimensions are recommendations derived from practical experience and system-related constraints rather than strategic experimental testing. Solid free-form glass parts produced with 3DPM glass casting are limited to the kiln size where the glass can be placed for the annealing process. Increasing volume can increase annealing times significantly for solid cast glass parts. Wall thick- nesses of the mold need to be defined in relation to the specific hydrostatic pressure in the mold.

Molds below 15 × 15 × 10 cm size with 20 mm thickness remained stable during experiments, while molds above 25 × 25 × 25 cm size broke and had to be cast with a metal support box. For glass casting of complex molds, a targeted viscosity calibration is required. Further work could investigate the specific criteria through experiments. For the production of hollow freeform parts with 3DPM glass blowing, the part size is limited to the bubble size the artisan or machine can produce. A top inlet is required to allow for the glass bubble to enter. Narrow gaps or pointy geometries are challenging to produce, while surface continuity is advantageous for glass blowing. Single reuse for glass parts that are not enclosed was successful in experiments; however, segmentation is required for mold removal. The size is also limited to the kiln size for the production of doubly curved glass parts using 3DPM slumping. It is recommended by the printing company that segments should not exceed 45 × 45 × 25 cm as stress cracks occurred during tests, and parts might break during removal from the print box. In the slumping process, undercuts cannot be produced, and narrow cur-vatures are feasible. The specific limitations for double curvatures are investigated in Sect. 4.3.

Table 6 3DPM Glass typologies - Full size table

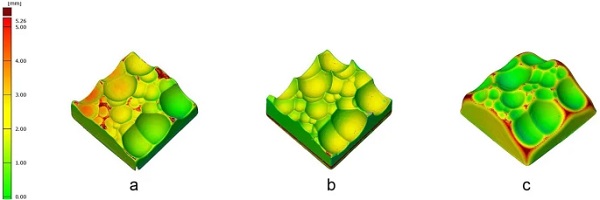

4.2 Level of precision

This section examines the precision of the mold and cast, blown and slumped glass elements com- pared to the digital input model.

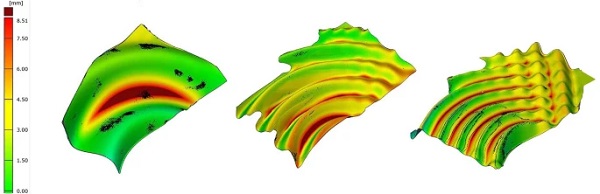

Mold precision For identifying the precision of the printed molds along different stages of the manufacturing process, molds were 3D scanned using the GOM ATOS CORE 300 scanner prior to coating (Fig. 8a), after coating (Fig. 8b), and after kilning (Fig. 8c). Figure 8 shows the deviations from the digital model along the process. The 3D-printed sand mold is exact with deviations of < 0.25 mm from the digital model. After the thin coating of 50µm is applied, the geometry deviates less than 0.25 mm from the digital model. After kilning, the mold shows some deformations along the sharp edges and outer surfaces of < 0.75 mm deviation.

Kiln and foundry casting Scans of the parts demonstrate that kiln and foundry cast glass can be fabricated with high precision with less than 1mm deviation in the surface area (Fig. 9a and b). However, the foundry cast glass demonstrates more substantial deviations of < 5mm along fragile edges (Fig. 9a). Kiln-cast glass results in higher precision with < 1.5 mm deviation along the entire part (Fig. 9b).

Blow molding Blow molding achieves high precision of < 1 mm in areas where the glass can immediately touch the mold when inflated. However, gaps or notches do not allow the blown glass to fully enter, resulting in deviations of up to 5mm from the 3D model (Fig. 9c).

Slumping The precision of results created using the slumping process is highly dependent on the heat curve and intensity of curvature. Scans identify high precision on tipping points of the geometry and maximum deviations of 9mm in the valleys (Fig. 10). For peak temperatures of 675 °C (kilning schedule C), deviations of 6mm were measured in the valleys of the mold. For peak temperatures of 800 °C (kilning schedule D), deviations of 9mm were measured in the valleys of the mold. Maximum deviations were observed at the edges of the mold as the glass was pulled away from the edges into the valleys of the geometry at 800 °C peak temperature. The control of the edges poses a challenge specific to glass slumping. The glass thickness was significantly varying in the case of the 800 °C kilning curves, which resulted in fragile stretched glass at the tips of the geometry, while the 675 °C tests did not vary significantly in thickness.

4.3 Geometric freedom and limitations

Beyond the overview of typology-specific geometric freedom and limitations, this section investigates slumped glass’s geometric freedom and limitations through experiments. To our knowledge, there is no standardized method for determining geometric freedom. Due to the lack of methods in place, this section focuses on examining the geo-metric limitations of slumped glass as which can be examined in a relevant manner through varying curvature intensities. For glass casting and blowing, the requirements are more complex and the scope of such investigations would require a separate publication. Therefore, the following factors were examined as these enable a good comparability and assessment for slumped glass that is relevant to practice.

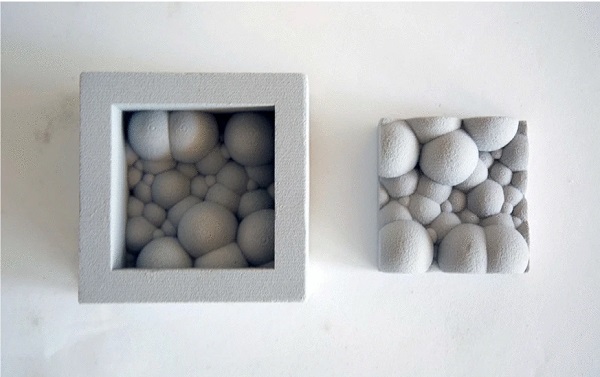

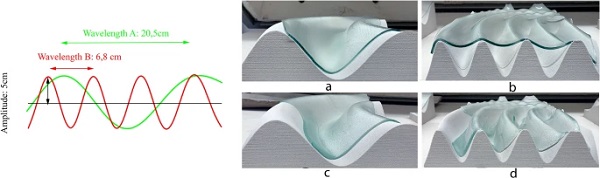

For the examination of curvature limitations of sheet glass slumping, three molds with double curvature with varying wavelengths (Fig. 11) are computationally designed and tested along two different heat curves with 675 °C (Kilning schedule C) and 800 °C peak temperature (Kilning schedule D). While the wider curvature (Fig. 11a, c) can be achieved with both heat curves, steeper curvature (Fig. 11b, d) can only be achieved with higher slumping temperature. For the steeper curvature the glass pane remains almost flat at 675 °C despite a slight deformation (Fig. 11b). For testing the geometric freedom and limitations of the cast and blown glass experimentally, a range of tests would be required that exceed the framework of this overview paper. Developing a set of standardized tests that can address the complexity of the geometric limitations of glass casting could enable parameter-based engineering of the mold independent of practitioners’ experience.

4.4 Possible challenges

In the glass shaping process, specific complications can occur for each method that can lead to defects in the glass artifact, such as:

Glass casting

- Gas developments in the mold are caused by humidity in the mold or reactions with the binder material.

- Breakage of the mold due to thin wall thickness or significant hydrostatic pressure in the casting moment.

- Cold cracks result from a miscalibrated anneal-ing and cooling process.

- Mold material leftovers enclosed in the glass cannot be removed.

- Holes due to a blockage of glass flow during casting.

Glass blowing

- Blown glass cannot shape into bottlenecks or narrow gaps.

- Blown hollow glass part gets stuck in the mold and can only be removed through breakage.

- Precise closure of the glass volume at the location of the air inlet.

Slumping

- Glass breaks at the peak point of the geometry due to high viscosity/temperature.

- Glass does not shape into valleys of geometry.

- Deformation and control of the edges of the glass pane.

4.5 Cost and time for mold production

3D-printed sand molds offer a significant economic time and cost advantage over CNC-milled steel molds for small lot sizes and other disposable molding techniques such as the lost-wax technique. This section summarizes the costs and time for producing the molds used in this research. The cost for 3D-printed sand mold as an industrial service is approximately 5 Euros/literFootnote3 with no further cost for the processing of the mold itself. The cost is calculated based on print space volume required, not on the volume of bound sand. Specifically, this results in costs of approximately 12 Euros for the 15 × 15 × 10 cm (2.25 liters) molds with a convex curvature, 1.50 Euros for the small 7 × 7 × 6 cm (0.3 liters) molds for 50mm glass spheres, and approximately 72 Euros for the doubly curved molds 30 × 48 × 10 cm (14.4 liters) mold.

The inorganic binder jetting process takes nine hours per print box of 180 × 100 × 40 cm (720 liters) volume with one additional hour of hardening the coating of 2m2 mold surface assuming 50µm coating thickness when diluted with ethanol. The time required for the immersion coating process is short, but a drying process of approximately two days has to be considered during which the coating can dry, and alcohol can evaporate. In conclusion, 3D-printed sand molds offer a low-cost and time-saving molding approach for glass.

5 Conclusions

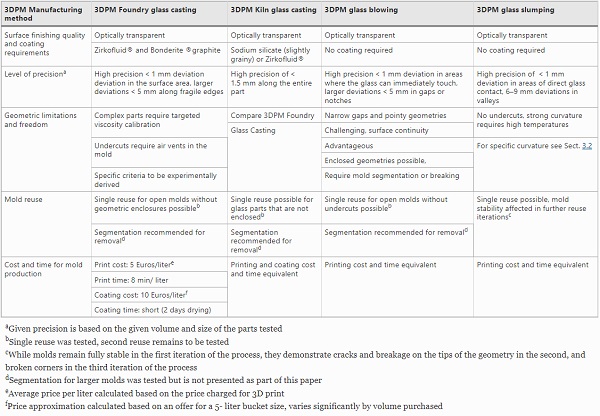

This section presents the conclusions of this research. Table 7 provides an overview of the results per manufacturing method.

Table 7 Overview of results per manufacturing method - Full size table

The general conclusions of the presented research are:

- Indirect application of additive manufacturing: This research presents an indirect application of binder jetting for glass making and provides a proof of concept for the compatibility of 3D- printed sand molds with foundry casting, kiln time. Thus, the printing time in the case of an entire print box can be approximated with 8 minutes/liter. In cases where the coating is required, the coating and its application are a minor additional cost factor. The cost for the Zirkofluid® coatings can be approximated with 10 Euros/liter for low purchase volumesFootnote4 which is sufficient for casting, blow molding, slumping of glass. Beyond previous research, the method opens up a wide range of options to digitally design and manufacture three-dimensional solid, hollow, and doubly curved parts. While traditional molding methods such as lost wax-casting are laborious and challenging in terms of precision, 3DP molds provide a precise, low-cost molding method for complex glass parts in low production numbers.

- Design investigations and typologies: The development of the molding strategy is highly dependent on the required precision, production number, and typology of the custom glass part. This research investigates the design related aspects for the correct choice of manufacturing method and the constraints and aspects of each method.

The glass quality-related conclusions of the presented research are:

- Surface finishing quality: The surface finishing quality of the glass parts that can be achieved with 3D-printed sand molds is highly dependent on the coating and glass processing method’s performance. Kiln cast glass demonstrates transparent glass results enabled by sodium silicate and Zirkofluid® coating. While both result in a clear glass surface, the sodium silicate coating shows grainy surface properties resulting from the sand. Zirkofluid®, applied in an immersion coating process smoothens the grainy mold surface and produces transparent, smooth surfaces in kiln cast glass parts. To address the slight milkiness of foundry cast parts when using Zirkofluid® coating, tests with graphite lubricant spray show promising results to improve the surface quality further and achieve fully transparent results. The use of graphite lubricant could potentially also be beneficial for improving the surface property of kiln cast glass further and diminish slightly mat features. It was found that blown and slumped glass result in transparent surface properties with- out coating. Minor traces of sand grain in the glass could be eliminated by using Zirkofluid® coating to even out the grainy texture of the mold surface.

- Level of precision: The level of precision of the custom glass object produced with 3D-printed sand molds can vary depending on the glass manufacturing method used. The 3D-printed molds themselves produced with industrial binder jetting ensure a standardized quality of the mold with high precision of < 0.25 mm deviation from the digital model.

- Foundry and kiln cast glass parts demonstrate a similarly high degree of precision of < 1.5 mm. An exception is some areas with fragile, pointy features that seem to be affected by the foundry casting process resulting in local deviations of up to 5 mm. The resulting < 1.5 mm precision is based on the given volume and size of the parts. Larger volumes might exhibit less accuracy due to the natural shrinkage of the glass. Parts produced with blow molding result in high precision of less than 1mm in surface areas that the glass can easily reach during the inflation process. In regions where the glass cannot enter due to geo- metric blockage such as narrow gaps, deviations of up to 5mm occur. Slumping is the method most sensitive to imprecision as the accuracy is highly dependent on the heat curve parameters. The inaccuracy of slumped glass reached up to 9mm in experiments in the vertical axis. Despite the calibration of the sagging process, it is crucial to consider the boundary conditions of the slumped glass–which can strongly deform in the case of extreme curvature. The highest deviations were observed in the valleys of the mold and along at the edges as the glass was pulled away from the edges into the valleys of the geometry.

- Geometric freedom and limitations: The research provides a general overview of the geometric freedom and limitations for each method and resulting typology based on practical experiments as well as setup- and method-related limitations. Beyond this overview, the geometric freedom and limitations of double curvature in slumped glass were investigated through experiments. Tests along a varying sine curve wavelength in doubly curved molds demonstrate the limitations in curvature in relation to the heat curve applied as an exemplary test scenario. Further criteria for geometric limitations could be derived from tests that investigate in specific the geometric limitations of the other shaping system including casting and blow molding independent of practitioners’ experience. For glass casting, for example, this could include to investigate the flow capacity of glass under increasingly difficult geometric conditions. For blown glass, the shaping capacity of glass along discontinuous mold surfaces could be investigated.

The fabrication process-related conclusions of the presented research are:

- Possibility to reuse the mold: The single reuse of molds was tested for all methods. For all methods, molds remained fully stable in the first iteration of the process, thus demonstrating that single reuse of the mold is possible for open molds without geometric enclosures. It was observed that some molds could be easily removed without breakage and demonstrated good surface qualities after their removal. For glass slumping, second reuse was tested. The molds demonstrated cracks and breakage on the geometry tips in the second iteration and broken corners in the third iteration of the process. Based on the cracking pattern, we assume that the breakage is caused by mechanical force applied to the mold in locations first in touch with the glass pane and by the binder’s softening. The second reuse of the mold for kiln and foundry casting was not tested in this research and will be part of future investigations. Reusing the molds for casting would be facilitated by a segmented molding approach to ensure easy removal of the mold, which is especially required in the case of enclosed parts.

- Cost and time for mold production: 3D-printed sand molds offer a low-cost and time-saving molding approach for glass. Molds can be produced within several hours of printing time in an automated process. The inorganic binder jetting is an industrial method that can provide a lowcost solution at approximately 5 Euros/liter for individual parts. Binder jetting is continuously improving and increasingly becoming accessible as a service. In collaboration with a glass foundry or using a standard kiln, the method is easily accessible without additional specialized equipment.

6 Discussion

Digital Glass: The direct Additive Manufacturing (AM) of materials has made significant progress in the last years, especially for pastes and cementitious materials. However, digital fabrication methods for the glass are still in their infancy due to the difficulty of processing the material [Giesecke et al. 2022]. This paper provides an indirect application of AM for glass compatible with traditional artisanship to open up new possibilities for the manufacture of digitally crafted glass.

Novel design space for glass and possible applications: The presented methods open up new possibilities for glass manufacturing at various scales and applications. These new opportunities are available for glassmakers, designers, architects, and engineers to prototype high-end custom glass parts with novel geometric and optical properties. Areas of application for three-dimensional shaped glass parts could include design pieces, bricks and window panes, and facade elements.

Future work: Future research could investigate the geometric and scale limitations of the presented techniques. This could potentially include the investigation of the geometric limitations for glass casting and blow molding. For deriving a general set of rules for all methods presented in this research, a range of tests is required to address its complexity and ensure comparability with other methods. Strategic tests related to the hydrostatic pressure in molds and their stability during casting to derive wall thicknesses could enable the evidence-based engineering of molds. Furthermore, future work could investigate multi-component molds, the fabrication of building components for assembly at a large scale and their structural performance. These steps could enable new geometric, structural, and decorative features in glass architecture.

Notes

- Personal communication with a lead technician of Hüttenes-Albertus Group, August 19, 2021.

- Personal communication with Silitech AG, March 11, 2022.

- Average price per liter calculated based on the price charged for 3D print.

- Price approximation calculated based on an offer for a 5- liter bucket size, varies significantly by volume purchased.

References

Acknowledgements

The authors thank Andreas Müller and Leonard Stöckle from ExOne Germany, Holger Barth, David Hein, Julian Bernhardt, and Dr. Christian Lustig from the Hüttenes-Albertus Group for their technical support, Eduardo Arabiano, and Robert Niederer from the Glass Foundry Hergiswil for supporting this research. The authors acknowledge the support of Andreas Reusser, Heinz Richner, and Lex Reiter from the chair of Physical Chemistry of Building Materials, Dr. Falk Wittel from the chair of Computational Physics for Engineering Materials, and Robert Presl from the Institute of Geodesy and Photogrammetry at ETH Zurich.

Funding

Open access funding provided by Swiss Federal Institute of Technology Zurich.

Author information

Authors and Affiliations

Architecture, Digital Building Technologies, ETH Zurich, Stefano-Franscini-Platz, CH-8093, Zurich, Switzerland - Rena Giesecke & Benjamin Dillenburger

Corresponding author

Correspondence to Rena Giesecke.