Ing. Richard Bruckner

INOVA-LiSEC Technologiezentrum GmbH,

Peter-Lisec-Strasse 1,

3353 Seitenstetten

Austria

Abstract

The following approach describes a new encapsulation technology for glass-glass-modules using tempered thin glass as front and back sheets. In general, glass-glass PV-modules have huge advantages as far as mounting is concerned, as back rails can be used. Tempered thin glass additionally improves the durability, flexibility, light transmission and weight of PV-modules significantly.

By means of a hermetic sealing, the new approach is ideal for any kind of solar cell and allows free selection of laminating foils. Another interesting aspect is the massive energy saving reached during manufacturing. Standard methods and the new frameless glass-glass PV-module production will be compared in the following.

.jpg)

Figure 1. Thin glass provides better light transmission – absorption proportional to glass thickness.

Introduction

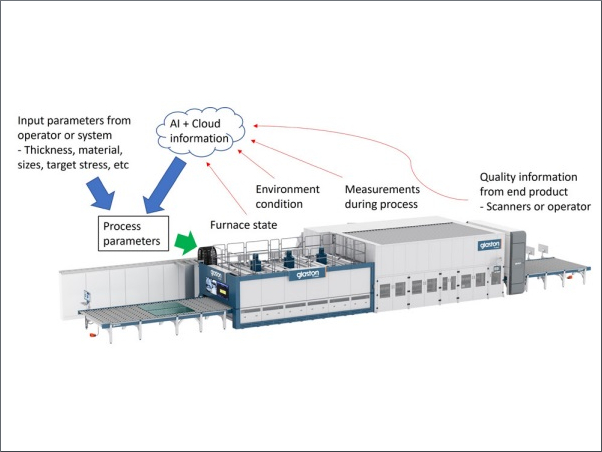

In the last few years, LiSEC has introduced the revolutionary flatbed tempering process, which enables extremely thin glass to be tempered at an excellent quality and without any roller waves. Thin glass is tempered in a LiSEC Flatbed tempering oven which ensures uniform microstructures with a very high density and tensile strength of the surfaces.

Thanks to the high convection air cushion system, which serves as both handling and heating system within the furnace, surfaces of the glass sheets are not being touched during the whole tempering process. Whether it is float glass, rolled glass or coated glass (one or both sides coating), glass processed this way is extremely thin and flexible and shows only lowest optical distortions.

.jpg)

Figure 2. Heavily loaded glass-glass PV-module as proof for resistibility and robustness.

The enormous resistance and flexibility of tempered thin glass now serve as a basis for a new concept of extremely light-weight PV-glass-glass-modules. With a glass thickness of 2 mm of both front and back side and a hermetic sealing along the edges, the glass-glass-modules are extraordinarily efficient and diffusion-proof. Ammonia gases, high ambient air temperature or humidity cannot cause harm to the module.

Thanks to the hermetical sealing with reactive hot melt any kind of foils can be used and there are no high requirements for the foils. Furthermore, this encapsulation method does not require any aluminium frames and can be assembled easily using the back rail method. The frameless and lightweight modules open up new possibilities for BiPV applications.

Additionally adhesive bonds also can be easily put in practice. Thanks to their flexibility the glass-glass modules are very durable and robust even with high area loads (fig. 2). As figure 3 shows symmetrical construction of glass-glass PV-modules using tempered thin glass keeps cells in a neutral phase while bending the module.

.jpg)

Table 1. Energy balance PV module/m2.

The 2 mm front sheet provides optimum light transmission resulting up in up to 6% more energy yield. The absorption is proportional to the glass thickness. Thanks to thin glass the whole encapsulation process is speeded up as thin glass heats up faster. Conversely temperature-discharge of cells benefits from thin glass too. With a weight of only about 10 kg/m2 the modules are extremely light-weight compared to conventional ones.

Applying this method LiSEC manufactured a big PV-module to show the potential in this area. With an overall size of 3260 x 1525 mm (180 cells = 770 Wp) and a total weight of only 50 kg the PV-module was manufactured in one piece.

.jpg)

Figure 4. PV-Module thickness is only ~6mm.

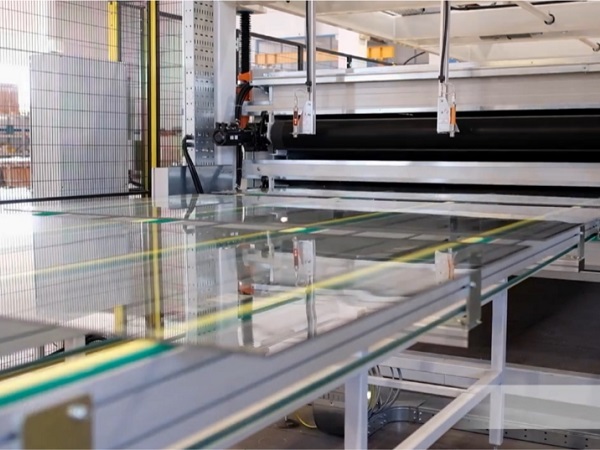

For the production of these modules, LiSEC developed a fully automatic production line especially designed for the glass-glass encapsulation approach. An integrated part of the method is a new vacuum laminator, enabling that up to 4 modules are processed simultaneously.

Curing of EVA, PVB or any other foil material is made in a separate batch curing oven. Because of the use of thin glass and the fact that there is no need for aluminium frames, the glass-glass encapsulation method yields an overall energy balance improved by more than 50% per m2 compared to conventional modules.

.jpg)

Figure 5. Point impact test (approx. 400 kg)

Thanks to the encapsulation technology with glass-glass modules and the hermetic sealing manufacturers are independent from the kind of solar cell or thin film used. The method is ideal for crystalline, organic or thin foil sells.

.jpg)

Figure 6. Hail test with tempered thin glass.

Summary

This approach for highly efficient PV-modules solves multiple problems observed with conventional backsheet-based PV-module encapsulation methods and is a significant step forward to energy savings and grid parity. Furthermore, it opens doors to new frameless BiPV ideas, low-cost roofing applications for glass houses, green buildings, car ports and many other things. Tempered thin glass is the basis for this new approach and grants better light transmission plus unreached flexibility and durability of PV-modules.

Figure 3. Cells are in the neutral phase of bending tension.