The OPC 40301 is an initiative of the VDMA, aimed at fostering collaboration and standardization within the industrial automation sector.

This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors:

- Dr. Markus Schoisswohl - Hegla New Technology GmbH & Co KG

- Dr. Klaus Mühlhans – A+W Software GmbH, Gesine Bergmann – VDMA e.V.

Abstract

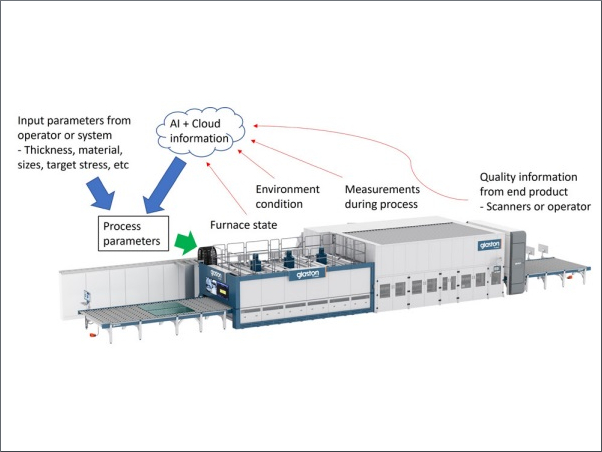

Digitalization of machines require standardized language for machine communication for which OPC-UA is a perfect choice. At GPD2019, VDMA e.V. announced the constitution of our OPC-Foundation - VDMA - joint working group for defining the requirements of the flat glass industry regarding an OPC-UA Companion Specification (CS) for flat glass processing machinery. Now, 4 years later, we can look proud of the established standard communication for flat glass processing machinery. Ambitioned, we continued to further develop the standard focused on harmonization of recipe structures for different types of glass processing machines as well as machine feedback, allowing compliance with KPI Standard such as ISO 22400.

Introduction

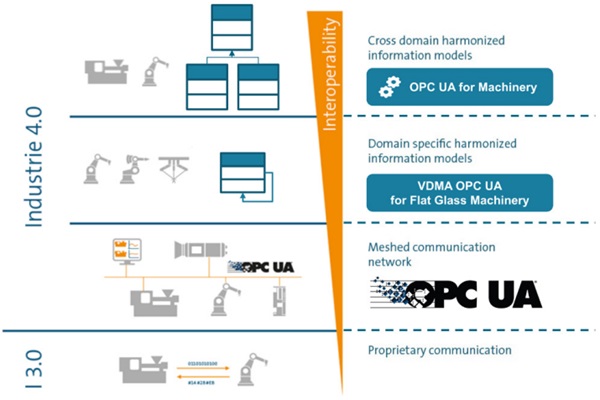

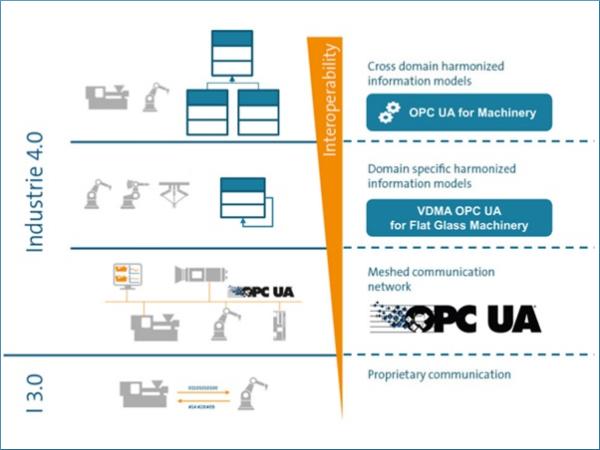

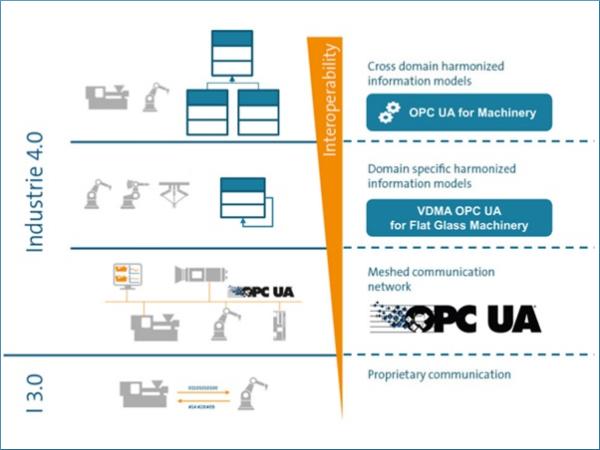

A base requirement for digitalization is that machines, such as humans, talk the same language for passing information easily from one to another. Within Industry 4.0, the digitalization of the production, OPC-UA has been established as major communication language (such as English in common literature and conferences). Like in any language there is a domain specific slang with dedicated words and meanings. In the digital world this “slang” is covered by companion specifications (see Figure 1). The application of such standards enables the replacement of individual cost and care intensive proprietary interfaces between machines, with the benefit of saving time and money for integrating machines into the production environment and minimizing the risk of failures during ramp up of production.

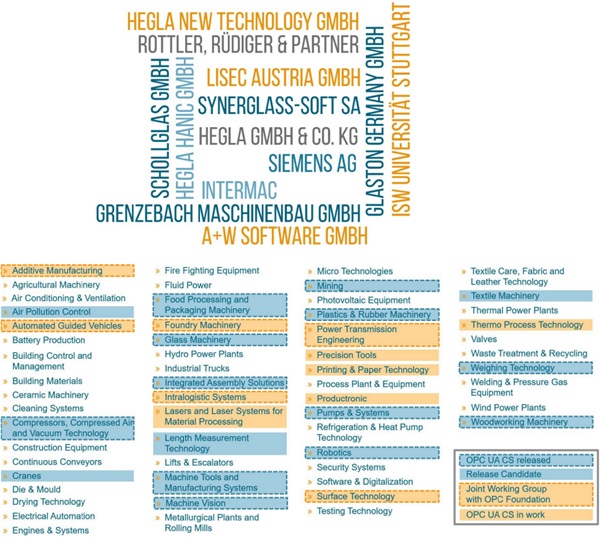

We are proud that within a group of most prestigious European suppliers for solutions for the flat glass processing, we created and released the OPC UA Companion Specification 40301 for Flat Glass Processing in January 2022. With regards to details, please refer to the specification itself and presentations done at GPD – Huddle 2022 and glasstec 2022.

In 2022 we expanded our work heavily towards a working together with the established group for global standardization of machines in general. Our input, in particular with job and feedback from jobs, was well appreciated. This OPC UA Companion Specification for Machinery, incorporating in general all kinds of machines like robot, tooling machines is now based equally, extending the communication skills of our machines way beyond the core of flat glass production.

To get OPC 40301 into practical use, however, we are about to publish a recipe definition based on a VDMA standard allowing to replace existing interfaces in our industry completely. Hence, we will briefly present our next targets and a short overview regarding our recipe definition.

Hurdles to get down to the field

Having a CS ready is just the first step in the story. Machine and MES manufacturers need to incorporate this standard into their communication standards. OPC 40301 addresses one major area: Job-Control. But: Knowing a job needs to be done does not automatically imply the machine knowing how to perform it.

Today, each machine used in the field within flat glass processing industry requires its own instruction set, typically a flat file transferred via network. Just providing Job-Control on top, even being a standard, does not solve the issue of having so many different interfaces in place. Hence, motivation to implement just this part is rater low.

As a consequence, we do need to add a standardized recipe definition. Basically, this definition should be part of a CS but the effort to agree on a CS and establish a standard at this level is quite high. This results in selecting a lower, easier to achieve standard: A VDMASpecification VDMA 24124 !

This approach allowed us to focus on the core needs of our industry and to establish a more simple standard based on Google-ProtocolBuffer type definitions. Having OPC 40301 and our VDMA 24124 at hand, machine, and MES manufacturers are now in a position to use one common standard replacing all existing interfaces!

Job Control

OPC 40301 Our next targets yielding for version 1.1 of OPC 40301 are:

- eliminate some difficulties detected when trying to implement OPC 40301,

- compare our definitions of coordinate systems to ISO 841 and try to align as far as possible,

- approve our CS by challenging it with further real world examples,

- celebrating another plugfest to actually combine lots of machinery and MES.

The main target, still, being to get OPC 40301 used in the field as soon as possible! For a better understanding, the core element of OPC 40301 is presented now.

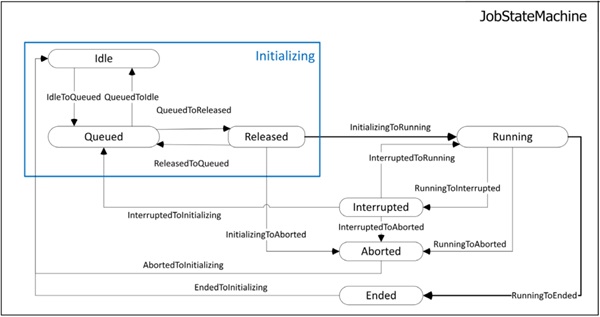

The processes required for execution of jobs such as

- Generating a job

- Holding a list of jobs (dishwasher clearing, lawn mowing, balustrade painting)

- Requesting jobs (I am bored, give me a duty)

- Sending jobs (ordering a job like “mow the lawn!”)

- And obtaining information about the execution of the job (“Darling I finished painting”),

were determined and put in relation to each other as seen in Figure 2 below. Importance was drawn to divide the processes strictly between ordering system (production planning system) and machines.

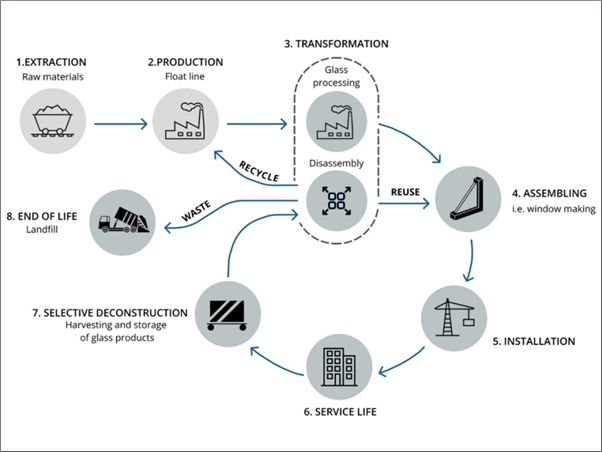

Based on those workflow and job requirements the semantics were detailed in such a way that they are compliant to applications from raw material warehouse via cutting, edge and surface processing, tempering, lamination up to IG production.

Given this definition within OPC 40301, the Recipe definition VDMA 24124 defines WHAT to execute when the machine is running.

Recipe definition VDMA 24124

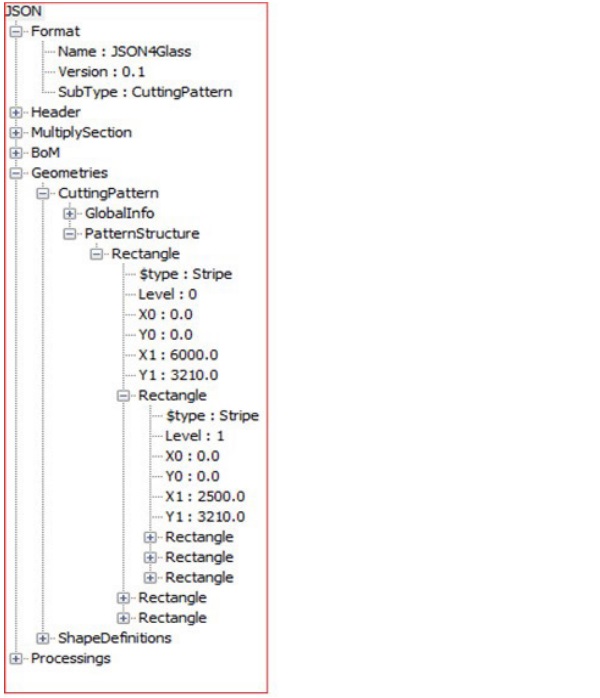

The work related to VDMA 24124 started with the challenge to achieve a global standard for our industry while keeping the resulting definitions still human readable in the field. Based on the requests, the decision was quickly taken to use JSON type Tag-Value based descriptions. JSON formats are easy to expand and easy to read for a human.

Unfortunately, JSON itself is such an open standard that by itself it is quite difficult to agree on a specific format. That is why we decided to use Google Protocol Buffer definitions as a guideline (see www. https:// protobuf.dev). Within this environment, various tools and libraries exist as well to ease development.

Starting with the cutting process we identified the related objects and used them to define our structure. One of the basic objects within the definition is a Rectangle which in itself may contain other Rectangles (recursive definition). An example for a cutting pattern might, therefore, look like this (see Figure 3).

Summary: from the Tower of Babylon to Machine Esperanto

The OPC-UA CS 40301 and the VDMA 24124 are the result of a joint open-minded effort of numerous prime glass machinery and software suppliers, standardizing for the time being the communication of jobs (work orders) and respective feedback. Such standardization is of superior importance on the path towards “plug and produce” reducing time and effort with respect to interfaces for machine-tomachine communication. The actual status is only the beginning of a continuous way of standardization on which we are working at the moment.

Many thanks to the current members of the working group:

A+W Software GmbH, Glaston Germany GmbH, Grenzebach Maschinenbau GmbH, HEGLA GmbH & Co. KG, HEGLA HANIC GmbH, HEGLA New Technologies GmbH, ISW Universität Stuttgart, LiSEC Austria GmbH, Rottler, Rüdiger & Partner, Schollglas GmbH, Siemens AG, Synerglass-Soft S.A., (Intermac, ISRA Vision AG)

Comments

Wow. Congratulations!