Author: Luc Moeyersons

This information corresponds to our current knowledge on this subject. It is offered solely to provide possible suggestions for your own experimentations. It is not intended, however, to substitute for any testing you may need to conduct to determine for yourself the suitability of our advice for your particular purposes.

This information may be subject to revision as new knowledge and experience become available. Since we cannot anticipate all variations in actual end-use conditions, LAMI-Solutions makes no warranties and assumes no liability in connection with any use of this information.

Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe any patent right.

TABLE OF CONTENTS

1. Introduction

1.1. Stages of production

1.2. Comments

2. Preparation of glass

2.1. Stages of production

2.2. The glass

2.3. Unloading the glass

2.4. Cutting the glass

2.5. Breaking out of the glass

2.6. Seaming

2.7. Washing

2.8. Separating Agent

2.9. Ceramic band

2.10. Coated glass

3. Bending the glass

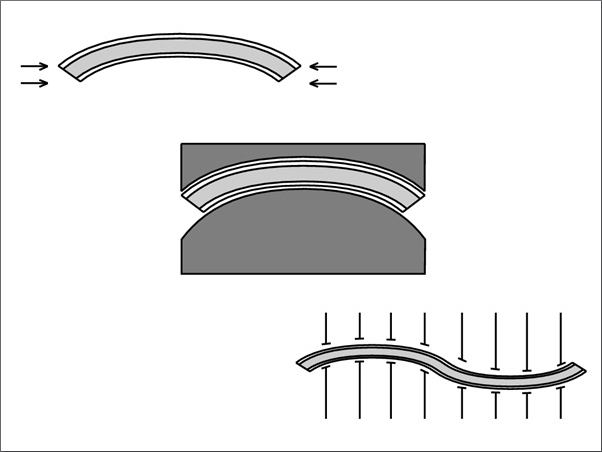

3.1. Sag bending

3.2. Press bending

3.3. Press assisted bending

4. PVB Preparation

4.1. Stages of preparation

4.2. Interleaved – Refrigerated

4.3. Packaging

4.4. Unwinding the roll

4.5. Adhesion & Moisture control

4.6. Stretching

5. Assembly

5.1. Preparation of glass

5.2. Assembly room

6. Prepressing

6.1. A look at different processes

6.2. vacuum ring process

6.3. vacuum bag process

6.4. Roller process

6.5. Ovens in use

6.6. Edge sealants

6.7. Use of clips

6.8. Windscreen stacking

7. Autoclaving

7.1. A look at different autoclaves

7.2. The purpose of autoclaving

7.3. Operational parameters

7.4. Risk of volatiles evaporation & autoclave fires

7.5. The ideal “practical” autoclave cycle

7.6. Possible autoclave cycle improvements

7.7. Recommended precautions

8. Windscreen finishing

8.1. Encapsulation

8.2. Trimming of excess PVB

9. Inspection

9.1. Defects in the glass

9.2. Defects in the PVB

9.3. Defects in the laminated glass

9.4. the shape of the windscreen

9.5. Laboratory testing

10. Lamination Defects

10.1. Bubbles

10.2. Bubbles: Rule of thumb on root cause

10.3 Delamination

5. Assembly

5.1.Preparation of glass

5.1.1. Without washing:

- The glass lites enter the assembly room at ambient temperature, if not used directly from the bending ovens.

- Most of the time, the glass can be dry cleaned before assembly.

- Vacuum cleaning is the most common method.

- Dimension of separating agent particles: between 25 and 40µ.(Superfloss™, Merck ® 8117)

- Problem: contamination by the separating agent.

5.1.2. Washing:

- The glass passes through a washer for bent glass. The conditioning of the water, along with the drying method, is very important.

- The quality of the water must be constant (especially rinse water).

- Use of air jets, to remove drops of water (and dissolved salts)

- Support points of windscreens.

- The washed glass can enter the assembly room at a slightly higher temperature. (ideal: washing with warm water (around 50° C) and rinsing with cold water (around 5° C) to reach a glass temperature after washing/rinsing/drying of 20°C)

5.2. Assembly room

5.2.1. Standards of cleanliness:

- Over pressure and air locks.

- Special hats and clothing.

- Static charges can attract dust.

- Filtered conditioned air.

- Only access by operators, no visitors, unless in special clothing.

- Avoid horizontal surfaces (dust collection).

- Daily cleaning of floor (with water)

- If vacuum cleaned, filter-unit/motor outside the clean room.

- Inspection lights are recommended

5.2.2. Windscreen assembly:

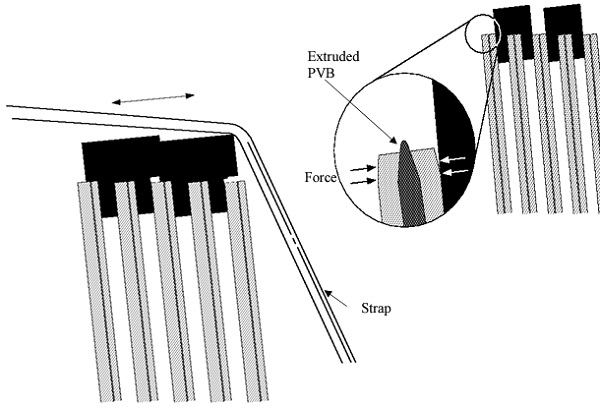

- The excess PVB is trimmed (max.: flush with glass in extrusion direction and 2 mm in opposite direction (A-Pilars)).

- Assembly problems:

- Contamination.

- Glass chips from trimming excess PVB.

- Shrinkage of PVB caused by the hot glass (due to thermal difference between PVB and glass).

6. Prepressing

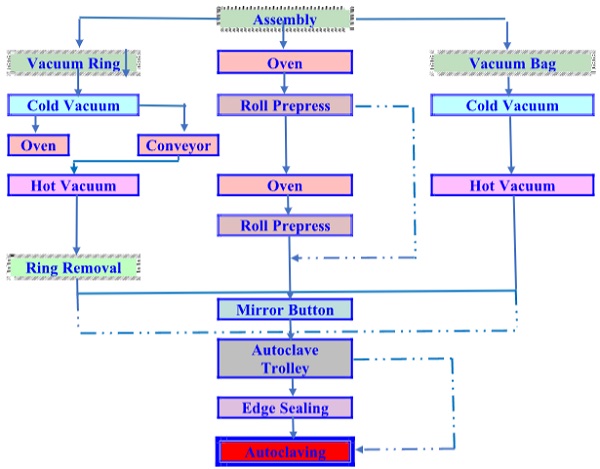

6.1. A look at different processes

6.1.1. Overall table:

6.1.2. The basic differences:

Vacuum:

- Optimal de-airing quality.

- No restrictions on the shape of the windscreens.

- Range of various shapes possible for one campaign (replacement market)

- Vacuum rings are very labour intensive.

- Vacuum bags:

- automated

- high investment.

Rolls:

- Good, but less effective de-airing.

- High speed.

- Large production runs of identical or similar shape windscreens.

- Automated.

6.2. Vacuum ring process

- Silicone rings are fitted on the perimeter of the windscreens. (some can be completely or partially made of a different polymer - risk of silicone contamination influencing the adhesion of “glue” during car assembly)

- Vacuum is applied to the ring to evacuate air:

◦ The ambient temperature vacuum is applied for 20 to 30 minutes.

◦ The rings must be cool to avoid edge pinching.

◦ The de-airing of rough pattern PVB is easier.

- The windscreens are heated whilst the rings are in place.

- Oven:

◦ Up to 100 deg. C (Air temp. = Glass temp.)

◦ The vacuum is maintained throughout the cycle.

- Vacuum conveyor:

◦ An “oven-tunnel”

- Air temperature:115 - 125 deg. C

- Glass Temperature at exit: app. 95 deg. C

- Cold de-airing: 20 minutes

- Oven Passage: 15 - 20 minutes

The vacuum is maintained throughout the cycle.

Ending of vacuum and ring removal at cooler temperatures ( < 40° C) helps to avoid “blow-ins” (edge defects).

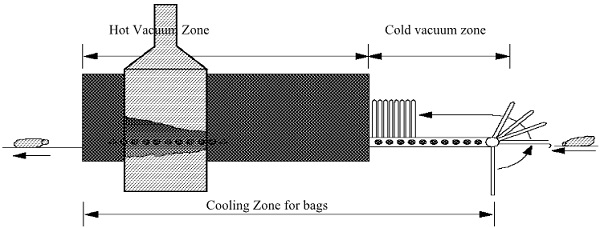

6.3. Vacuum bag process

- Old technology.

- Asahi process.(currently also Pilkington and Sekurit Saint-Gobain (Vetrotool)

- High investment but an excellent system.

- Important parameters:

◦ Temperatures of the bags.

◦ Temperatures of the glass.

◦ Life of the bags. (1-2 years)

◦ Specific vacuum of each bag.

◦ The heating cycle and temperature of the bags (especially at loading of the W/S sandwich).

- The system of the future:

◦ Highly curved windscreens.

◦ High production volumes

◦ Flexibility to deal with various W/S models within the same production run.

◦ Energy Consumption remains an issue.

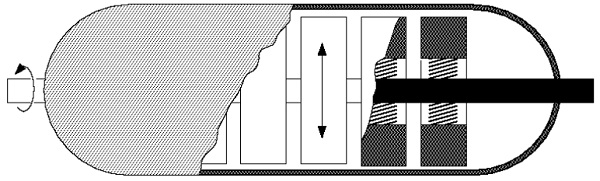

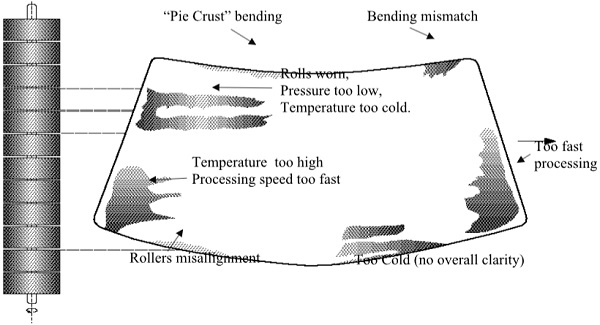

6.4. Roller process

6.4.1. Vertical rolls:

- Old system, “Artama”

- Spring-loaded segmented wheels on a fixed shaft contained in a rubber cover.

- A slow, labour intensive process. (automated by Pilkington)

6.4.2. Horizontal rolls:

- Made by Sack, Tecnoglass, Klöpper and Olbricht.

- Segmented roll system, with each roll on a separate axle, spring or hydraulic load.

- The windscreen pivots between the two layers of rolls.

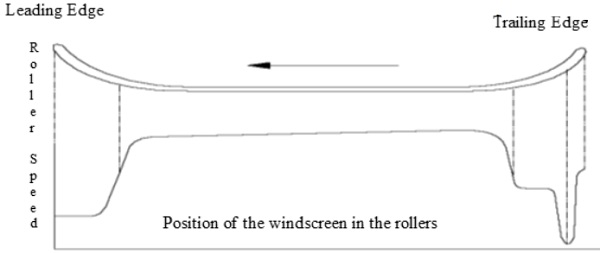

- The processing speed is programmable.

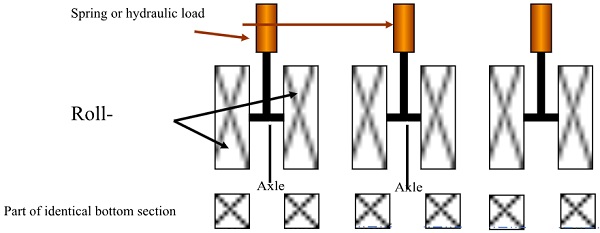

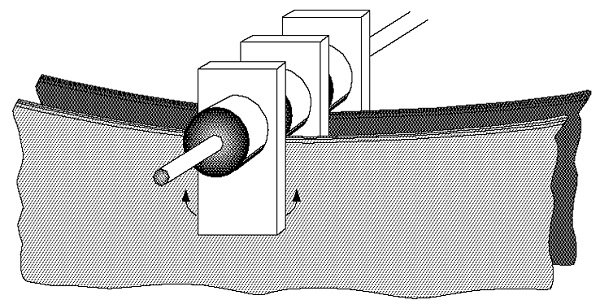

6.4.3. Single roll process:

- The principle: de-airing and tacking of PVB to glass in one single operation.

- Temperature: between 70 and 90 deg. C

- Speed: max. 5m/min.

- Programmable speed and differential heating necessary for good de-airing of trailing edge.

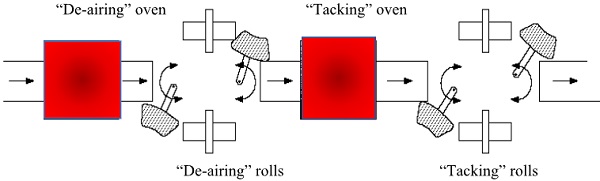

6.4.4. Double roll process:

- The principle: de-airing by first pair of rolls, sealing of edges by the second.

- Typical Configuration:

De-airing rolls:

- The glass temperature depends on the speed

- Between 50 and 60 deg. C

- The variable speed programme is important:

Faster rolling when risk of bubbles is low

◦ Applied on the flat part of the windscreen.

Slower rolling when the risk of bubbles is great. Applied on the curved parts of the windscreen, in particular on the trailing edge.

◦ Some adhesion is needed, not only deformation of the surface roughness:

- If the PVB is too hot or the speed too great, the rolls may jump over the air bubbles.

- If the PVB is too cold, the windscreen may open up after the rolling, allowing air to re-enter.

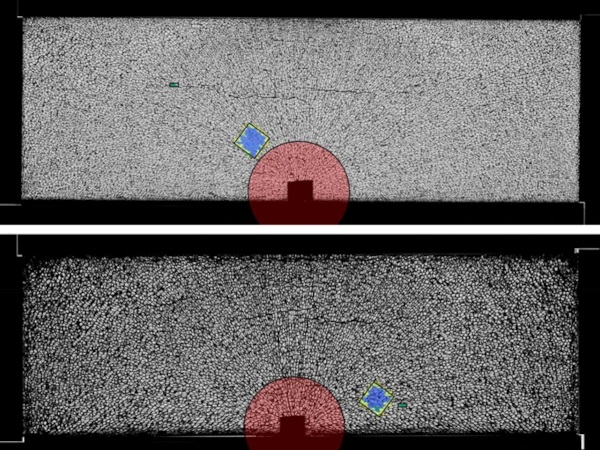

◦ The appearance gives an indication of the quality of calendering:

◦ Less transparent than vacuum prepress.

◦ Typical appearance.

“Tacking” rolls:

Edge sealing.

- To prevent compressed air penetration in between PVB and glass during autoclave cycle.

The air:

-is not removed

-is only moved to the trailing edge.

Glass temperature: 85-105 deg.C

6.5. Ovens in use

6.5.1. Convection (circulating air):

- The PVB is heated by thermal conduction through the glass.

- “Hot spots” at the edges.

6.5.2. Long wave IR:

- The IR heats the glass: the PVB is heated by thermal conduction.

6.5.3. Short wave IR:

- The glass is transparent to IR waves with a frequency higher then 3.5 µm.

- The PVB is not transparent at frequencies of 2.7µm.

- The PVB is heated through radiation.

- Heating from top and bottom necessary.

6.5.4. Micro-waves:

- Possible in theory, but not yet tested commercially.

6.6. Edge sealants

6.6.1. Use:

- Used to swell the PVB and to seal the edges before autoclaving.

- No stress on the glass as with the use of clips.

6.6.2. Types:

- Dowanol® TPM (Tripropylene glycol methyl ether)

6.6.3. Risks:

- Risk: autoclave fires. (low flashpoint)

- Risk of spontaneous ignition in the autoclave at the right concentrations.

- To be applied on hot glass, in a well de-aired area, to ensure evaporation of the excess.

6.6.4. Method of application:

- Applied with brushes, by vaporisation.

- NOT necessary when the bending is correct.

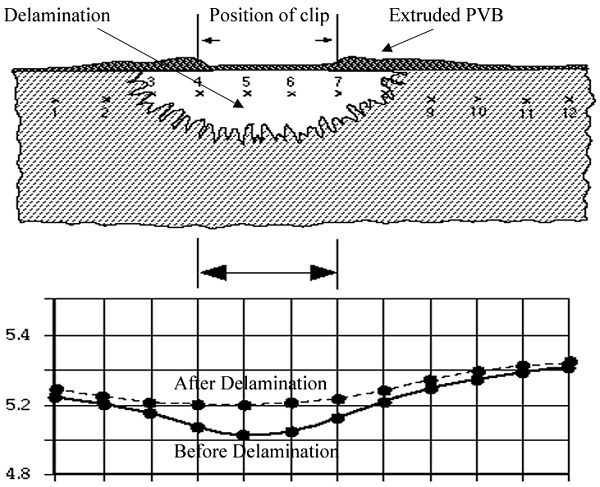

6.7. Use of clips

Frequently used in areas of poor sealing:

- Not a practice to be recommended, despite the possibility of recuperation.

- Can cause delamination.

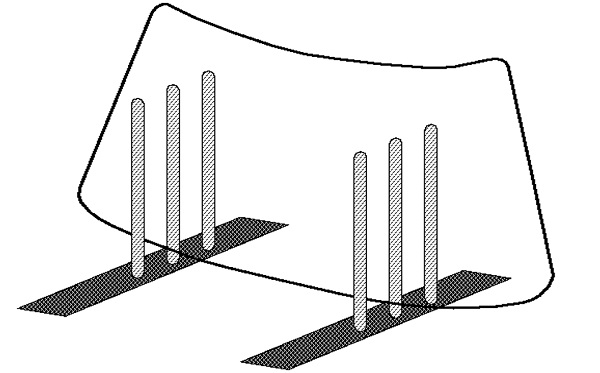

6.8. Windscreen stacking

6.8.1. Leaf separators:

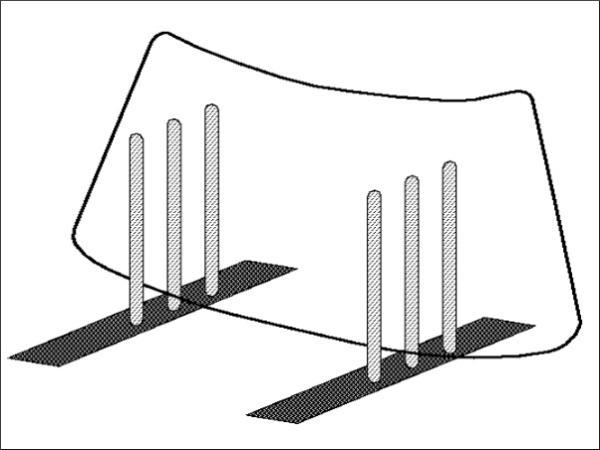

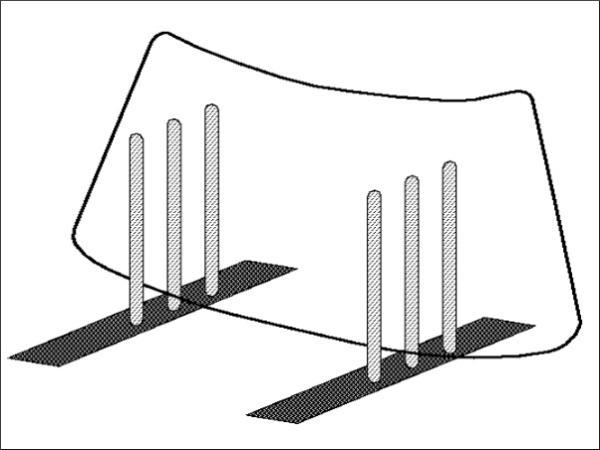

- Metal leaves (covered in plastic) are positioned on a fixed axis and hold the windscreens in a vertical position.

- Used for large volume production. (identical height W/S)

6.8.2. Rod separators:

- Can restrict the air flow in the autoclave.

- Possible distortion.

6.8.3. Block separators:

- Most commonly used.

- Wooden blocks can contribute to autoclave fires.

- ST nylon blocks.